A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 6

2 6

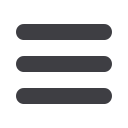

The device’s complex casing is

often made of magnesium or alumi-

num alloys. After years of service, the

housing becomes worn or damaged

beyond normal repair.

Many failures

are located at tight tolerance, heat-

sensitive areas such as stator bores,

exciter bores, pilots, mounting pads,

and mating faces (Fig. 3). These areas

are difficult to dimensionally restore

using conventional thermal methods

such as plasma flame spray.

With the

cold spray approach, these repairs are

both feasible and economically viable.

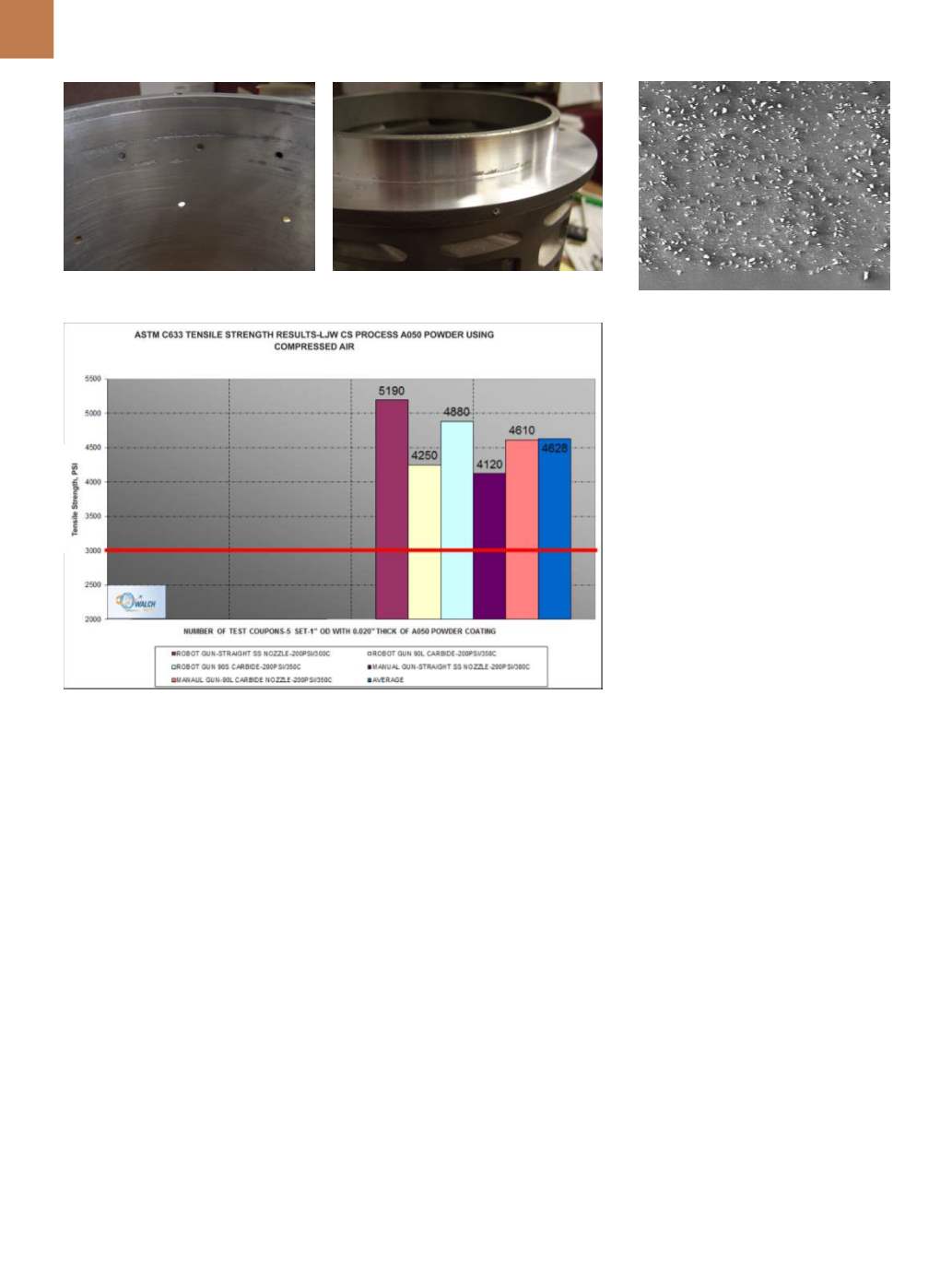

PROCESS QUALIFICATION

With regard to IDG repairs, pro-

cess qualification included selecting

optimum cold spray grade powders

(in this case, CenterLine SST A050) and

process parameters to produce coat-

ings within the required specifications.

Validation was successfully obtained

by ASTM C633 bond strength tests,

metallographic examination, and 90°

bend tests per the OEM’s repair vali-

dation specifications (Hamilton Sund-

strand SPR52). Bond strength results

indicate that all test samples failed at

stress levels well above the minimum

level required (Fig. 4). Metallographic

examination reveals a microstructure

with porosity levels of less than 2%, no

cracking, and no lack of bonding. A typ-

ical microstructure is shown in Fig. 5.

Further, 90° bend tests with the coating

in tension bent around a 0.25-in. radius

exhibit no spalling or chipping.

REPAIR PROCEDURE AND

QUALITY ASSURANCE

The following steps were taken

to ensure proper surface preparation,

repair, and inspection:

(a) Existing corroded and/or damaged

surfaces were removed.

(b)Spray deposition was facilitated by

pre-machining as necessary.

(c) Grit blasting or other methods

were used to prepare surfaces and

increase surface roughness.

(d)Robotic gun or manual cold spray

took place (Fig. 6a).

(e) Repairs were post-machined per

OEM engineering specifications

(Fig. 6b).

(f) Visual and dimensional inspection

occurred.

(g) Nondestructive examination took

place.

(h) Painting and/or anodizing was

performed as required to improve

corrosion performance (Fig. 7).

The main justification for using

cold spray in the restoration of these

types of components is its ability to

extend component lifespan at a fraction

of their OEM replacement cost, assum-

ing that the part is commercially avail-

able. In many instances, components

are no longer available, thus making

even stronger economic sense for cold

spray restoration. Figure 8 shows exam-

ples of the relative cost of replacement

of IDGs versus the cost of cold spray

restoration to meet required OEM

specifications.

CONCLUSION

Cold spray has become an essen-

tial tool that complements traditional

thermal spray methods for repair

and restoration of IDG housings used

Fig. 3 —

Pitting corrosion damage in a Boeing 747 APU generator housing. Courtesy of L.J. Walch.

Fig. 4 —

ASTM C633 qualification test results. Courtesy of L.J. Walch.

Fig. 5 —

Microstructure of SST A050

cold spray composite deposit showing

well-dispersed aluminum oxide particles

in an aluminummatrix. No lack of bonding

with porosity less than 2%. Substrate is

aluminum 6061. Courtesy of CenterLine

Windsor Ltd.