A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

2 2

at room temperature in either uniaxial

compression or using a double-shear

test fixture to approximately 5-8% engi-

neering strain.

SEM data were acquired using a

Carl Zeiss Sigma-VP FEG-SEM. Channel-

ing contrast images were taken at 10 kV

and 0° specimen tilt with a solid-state

backscattered electron detector, yield-

ing both channeling and atomic num-

ber contrast for visualization of slip

lines and

α

/

β

phase distribution. Sub-

sequently, EBSD maps were acquired

at 20 kV accelerating voltage and 70°

specimen tilt using an Oxford Instru-

ments NordlysNano EBSD detector.

During EBSD mapping, secondary elec-

tron and forward-scattered electron

detectors captured images of the EBSD

scan areas. Images and EBSD data were

collected from two locations for each

sample at a magnification sufficient to

examine approximately 50 grains.

After acquiring EBSD scans for

slip-trace analysis, the ATI 6-4 (condi-

tion 4) specimen was re-polished and

rescanned, saving EBSPs at 1344 x

1044 pixels for subsequent processing

with CrossCourt software (BLG Vantage

Software).

POST-ACQUISITION

DATA ANALYSIS

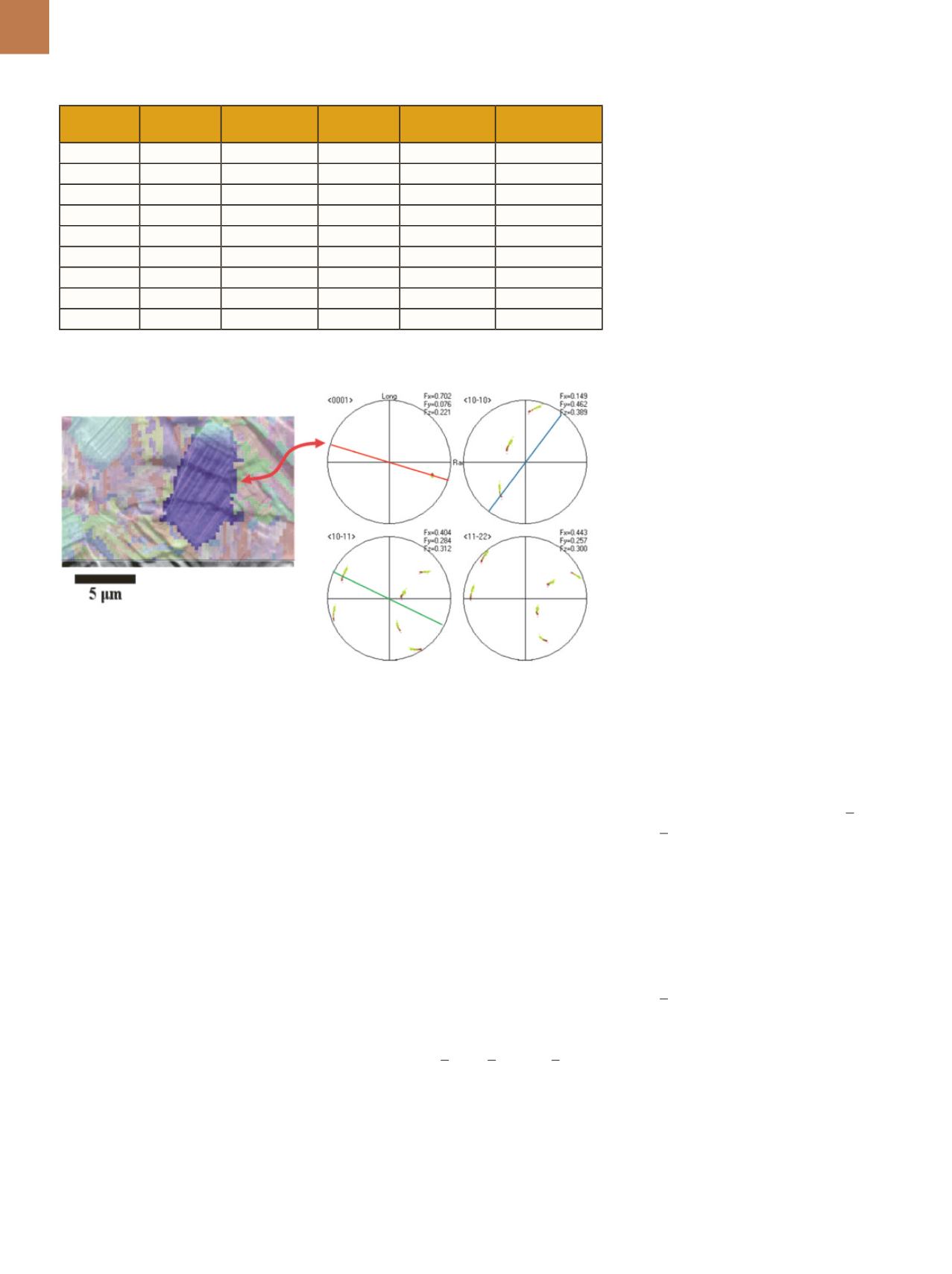

EBSD data from slip band analy-

sis was correlated with images using a

method described by T.R. Bieler, et al.

[2]

.

The trace of the slip line produced on

the polished surface was graphed onto

the {0002}, {1010}, {1011}, or {1122} pole

figures for the specific grain, and visu-

ally matched to intersections with the

plane normal, the intersection of which

identifies the slip system (basal, prism,

1st pyramidal, and 2nd pyramidal, re-

spectively) responsible for the defor-

mation. Between the two EBSD scans

per sample, 20 grains were analyzed for

each material and condition (Fig. 1).

In the HR-EBSD technique used

by CrossCourt 3 software

[3,4]

, the EBSP

of each pixel in a grain is compared

with a reference EBSP via two types of

cross-correlation analysis; one mea-

sures the unit cell distortion, and there-

fore, elastic strain at each pixel; and one

measures whole-body rotations, and,

therefore, plastic strains. The strains

are mapped onto the possible slip sys-

tems in the analyzed material

[4-6]

using

the configuration that yields the min-

imum dislocation line energy

[7]

. This

yields the lower bound of the geomet-

rically necessary dislocations (GND) re-

quired to produce the observed misori-

entation, with a detection threshold as

low as 10

12

lines/m

2

.

RESULTS

Multiple slip bands from each

family of slip systems were observed

in nearly all grains, conditions, and al-

loys. The frequency of each slip system

within a given material and condition

is shown in Table 2. Basal slip occurred

infrequently among all samples, and

loading orientation appeared inconse-

quential when comparing samples 2, 3,

and 4. Conversely, activation of prism

slip bands was significantly different be-

tween samples 2, 3, and 4, demonstrat-

ing that prism slip activation is texture

dependent based on the texture shown

in Fig. 2. It also appeared that {1010} and

{1011} slip bands formedmore frequent-

ly in annealed microstructures.

Figure 3 shows the results of recon-

structing dislocation content using HR-

EBSD analysis. Relevant Burgers vector

and line direction components were cal-

culated using the CrossCourt software

for each slip system, indicating that the

[1120] dislocations of both edge and

screw character were in greater number

density than other directions. However,

no maps show clear signs of slip band

formation, suggesting a difference in

activation energy or interaction of slip

bands within the bulk of the specimens.

DISCUSSION

The HR-EBSD technique is a good

fit for analyzing dislocations in bulk

TABLE 1

—

TEST MATERIALS AND CONDITIONS

Sample

number Material

Max. O

2

content, %

Product

form Condition Loading

direction

1

ATI 6-4

0.20

Wire

Q + A (a)

Longitudinal

2

ATI 6-4

0.20

Wire Annealed (b)

Longitudinal

3

ATI 6-4

0.20

Wire

Annealed

Radial

4

ATI 6-4

0.20

Wire

Annealed Double shear

5

ATI 6-4 ELI

0.13

Wire

Annealed Longitudinal

6

ATI 3-2.5

0.12

Wire

Q + A

Longitudinal

7

ATI 3-2.5

0.12

Wire

Annealed Longitudinal

8

ATI 425

0.30

Wire

Q + A

Longitudinal

9

ATI 425

0.30

Plate

Annealed Longitudinal

(a) Q+A =

α

/

β

solution treated, quenched, and aged. (b)

α

+

β

annealed structure.

Fig. 1 —

Slip line traces translated from the forward-scattered electron image onto the crystallo-

graphic pole figures of the purple grain (red arrow). Each colored line corresponds to a family of

slip lines in the image and with a single family of crystals.