A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 6

2 3

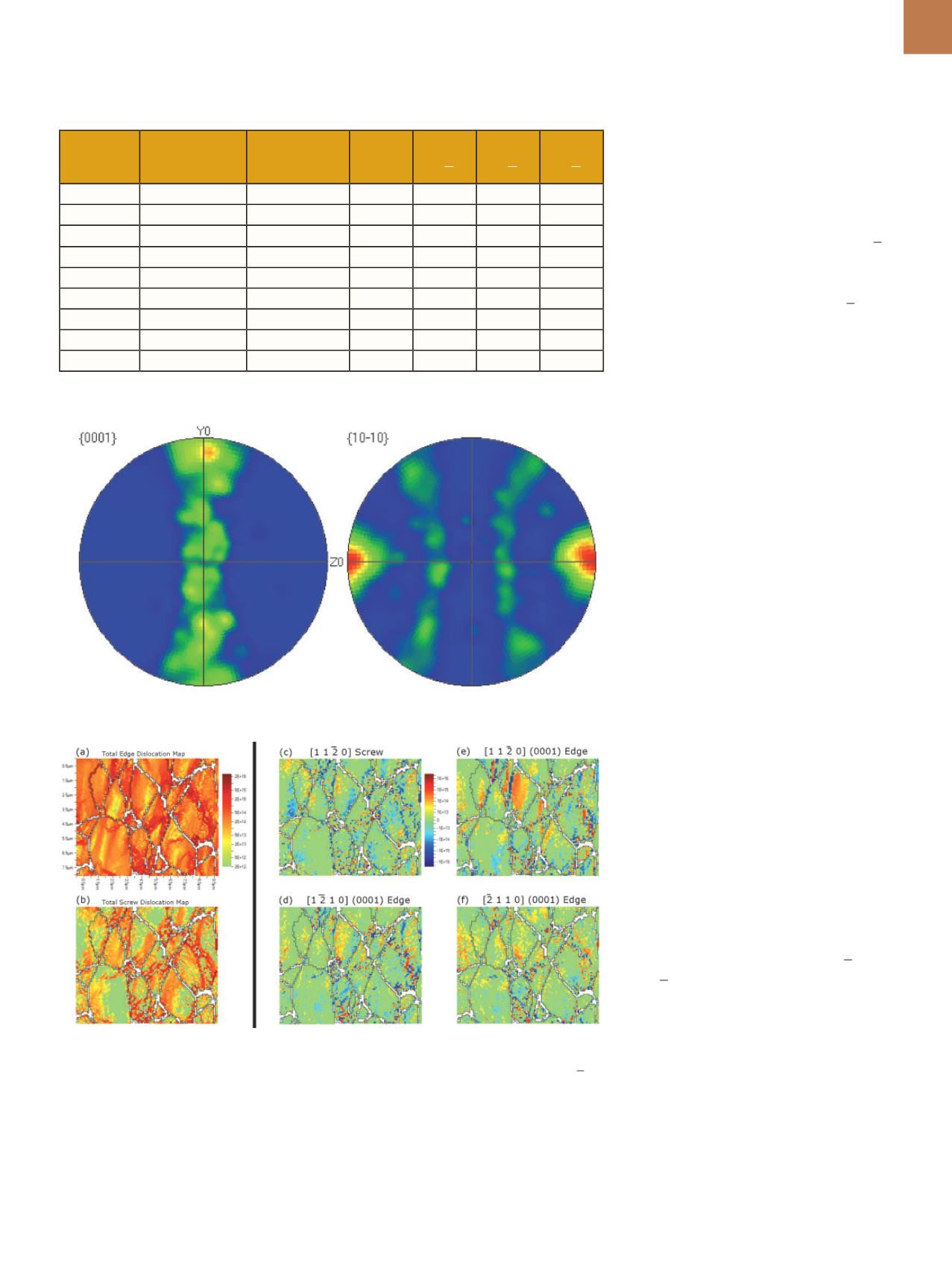

TABLE 2

—

FREQUENCY OF GRAINS WITH SLIP SYSTEM

ACTIVATION WITHIN MATERIAL AND CONDITION

Sample

number

Condition

Loading

direction

%

with

{0001}

%

with

{1010}

%

with

{1011}

%

with

{1122}

1

Q + A (a)

Longitudinal

10

30

30

50

2

Annealed (b)

Longitudinal

10

55

60

45

3

Annealed

Radial

20

20

55

40

4

Annealed

Shear

15

10

50

60

5

Annealed Longitudinal

15

55

55

70

6

Q + A

Longitudinal

10

15

60

55

7

Annealed Longitudinal

20

20

70

75

8

Q + A

Longitudinal

15

40

60

50

9

Annealed Longitudinal

10

50

75

35

(a) Q+A =

α

/

β

solution treated, quenched, and aged. (b)

α

+

β

annealed structure.

comparison, graphical slip band analy-

sis is a surface technique to study a sur-

face exposed to deformation. As such,

graphical slip band analysis might not

show the same results due to the nature

of the free surface during deformation.

Basedondata inTable 2, quenched

and aged microstructures demonstrate

a higher number of grains with {1122}

slip bands. Similarly, radial and shear

loading appears to decrease the num-

ber of grains demonstrating {1010} slip

bands. Finally, there is a significantly

greater number density of slip bands

and twinning in samples 6 and 7, which

had both lower aluminum content than

all other samples, and lower nominal

oxygen content than all samples except

sample 5. This confirms the general

trend that higher strength alloys tend to

have fewer activated slip bands, with a

greater overall intensity of deformation

on the remaining slip bands.

HR-EBSD results differ both from

that reported in the literature on disloca-

tion content visible in TEM and from slip

band EBSD mapping. The latter could

be explained by the differences of stress

state due to the free surface during de-

formation, while the former may be due

to image forces acting upon more mo-

bile edge dislocations in TEM foils during

analysis. The same trend with edge ver-

sus screwdislocation content in HR-EBSD

and TEM analysis has been observed in

other materials using CrossCourt soft-

ware. Further investigations could be un-

dertaken to prove the enhanced mobility

of edge dislocations in TEM foils using

ECCI on a TEM foil and a bulk sample to

compare the dislocation content.

HR-EBSD results show significant-

ly more basal slip thanmeasurement by

slip trace analysis, and less {1011} and

{1122} slip bands. This disparity might

be due to differences in the accuracy

of each technique, differences in EBSD

acquisition variables, or stress state at

the free surface; and could be further

explored by analyzing smaller strain

levels using both techniques. A differ-

ence in slip banding near surfaces could

be an important consideration for frac-

ture initiation mechanisms, such as in

fatigue, where cracks may originate at

either surface or subsurface sites.

Fig. 2 —

Pole figures generated from Sample 4. Wire longitudinal axis is aligned with Z0.

Fig. 3 —

Dislocation density analysis fromHR-EBSD technique for Sample 4. Direction of wire

longitudinal axis in maps is vertical. (a) Calculated edge dislocation content is larger than

(b) total screw dislocation content from all slip systems. (c) Screw dislocation content of [1120]

character. (d-f) Basal edge dislocation content fromdifferent vectors of basal dislocations.

materials, such as within the subsurface

of a fatigue sample

[8]

. The technique re-

quires preparation of only one polished

surface rather than two surfaces closely

spaced together like in TEM. Having

only one surface reduces the effect

of strain relaxation, which can occur

during soft-materials TEM analysis. By