FEATURE

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 5

6 7

11

existing boilers to fulfil excess steam demand. Therefore,

the cogenerator stays at full steam, maximizing the “free”

nitrogen delivered. ERC users include steel and copper-tube

manufacturers, aluminum manufacturers and many other

metal processing companies. Typical payback for supplied

ERC units ranges from six months to one year. ERC conducts

surveys at prospective plants todetermine the potential eco-

nomic value.

PROTECTIVE ATMOSPHERE

The high purity atmosphere produced by ERC cogen-

erators is well suited for annealing and many other metal-

processing applications. The output contains not only ni-

trogen (N

2

), but also the required reducing gases (H

2

and

CO) necessary for successful processing of metals to pro-

duce a superior bright finish. For annealing medium- and

high-carbon steels where decarburization must be avoided,

enhanced purification is provided to further reduce CO

2

, H

2

O

and O

2

to levels approaching those of 99.999% liquid nitro-

gen. The atmosphere is much more robust than straight ni-

trogen due the presence of H

2

and CO, and tolerates furnace

leaks and other sources of CO

2

, H

2

O and O

2

, while still pro-

ducing a superior metal finish.

GREEN TECHNOLOGY

Besides the direct economic benefit from nitrogen sav-

ings, the ERC unit can result in reduced emissions. Given that

the products of combustion from steam boiler operation

are not vented, but instead are recycled to the heat treat-

ing furnace, total emissions of the heat treating facility are

minimized. Especially when replacing nitrogen/endother-

mic systems, a study should be conducted to determine the

magnitude of a reduced carbon footprint, and the value of

potential credits to the facility.

CASE STUDY: QUALITY/COST UPGRADE

In 2010, a steel-tube manufacturer (PTC Alliance, Fair-

bury, Ill.) upgraded an existing furnace to enable processing

medium-carbon steel tubes, producing a bright finish with-

out decarburization on the inside or outside of the tubes.

Prior to the upgrade, the furnace was used to process low-

carbon steel tubes, and did not have the capability to pro-

duce tubes free of decarburization (whichwas not a problem

for themarket theywere serving). The goal of the project was

to convert the furnace to enable processing high-strength

automotive products.

The company consulted the furnace manufacturer

about making the necessary furnace conversion, and it was

recommended to take the traditional approachof converting

to nitrogen/endothermic atmosphere. Instead, the tube pro-

cessor selected an ERC cogenerator with enhanced purifica-

tion and RAD-CON atmosphere control system. The resulting

bright finish on the steel tubes exceeded expectations, and

met all decarburization specifications on the inside and out-

side of the tube. Today, the plant continues to successfully

produce tubes for this application.

OTHER APPLICATIONS

Other manufacturers that installed ERC cogenerators

over the past two decades include carbon-steel tube man-

ufacturers, steel-coil producers, companies producing steel

laminations for motors, aluminum producers, steel rod and

bar suppliers, steel golf-shaft manufacturers, copper and

brass tubing manufacturers, and producers of sheet steel.

For more information:

Christopher J. Messina, presi-

dent, RAD-CON Inc., Cleveland, OH, 440.463.4224 (mobile),

chris.messina@rad-con.com,

www.rad-con.com, or Bud

Weiland, ERC International Inc., part of the RAD-CON Group,

Cleveland, 440.610.6239 (mobile).

(a)

(b)

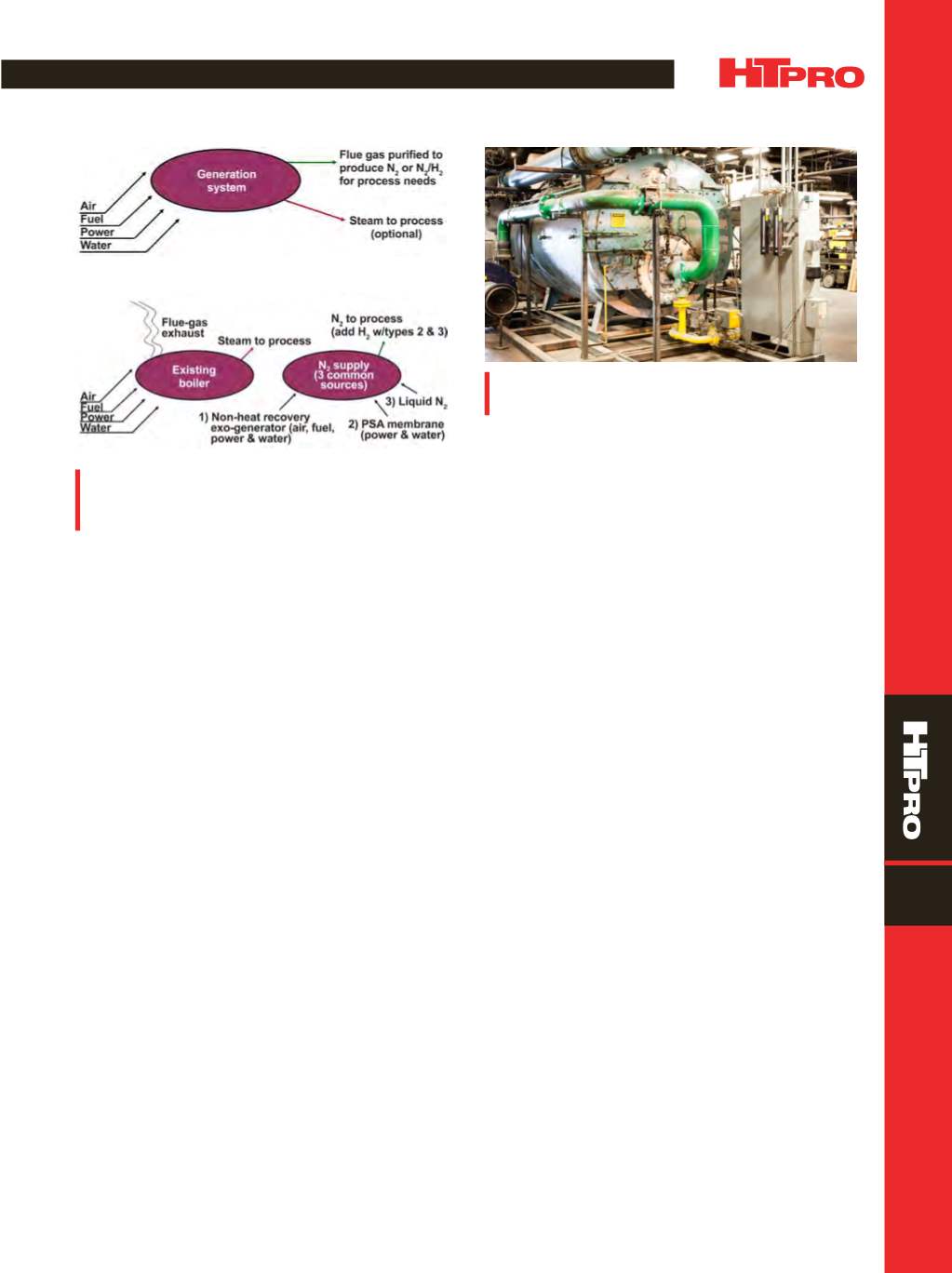

Facility with a traditional atmosphere-generation system (a)

and facility with the “atmosphere advantage” ERC cogenera-

tion system (b).

Steam/exo gas cogenerator for processing alloy-steel tubes at

PTC Alliance in Fairbury, Ill.