FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

6 4

8

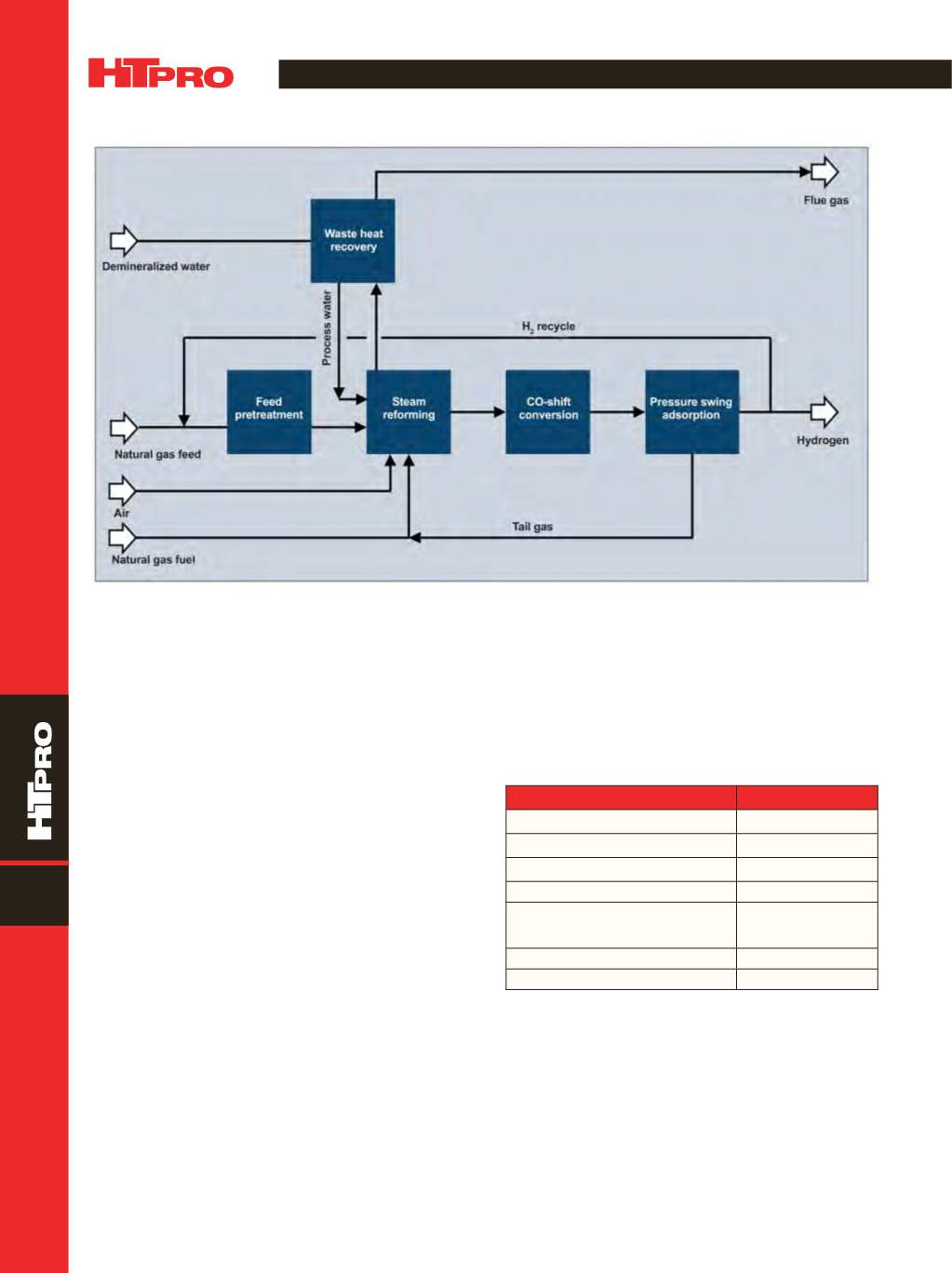

The overall reforming reactions are endothermic (re-

quire heat), which is supplied by the combustion of fuel. Tail

gas from the pressure swing adsorption (PSA) systemmeets

most of the fuel requirement with the rest being supplied by

natural gas.

The hydrogen-rich stream is purified using pressure

swing adsorption. PSA is a physical process that depends on

selective physical binding of gas molecules. Hydrogen is es-

sentially not adsorbed by the proprietary adsorbent materi-

al, amixture of carbonmolecular sieve and zeolites, because

it is nonpolar and highly volatile. The system operates on a

repeated cycle consisting of two basic steps: adsorption and

regeneration. Regeneration consists of depressuring, purg-

ing, and repressuring.

PLANT DESIGN

Inputs to the modular plant are natural gas, demin-

eralized water, and electric power. Outputs are high purity,

gaseous H

2

. There is no export steam. This plant produces H

2

with the following specifications:

•

Flow rate: 165-330 Nm

3

/h

•

Purity: 99.999+%

•

Pressure: 13.8 barg

The plant is designed to be easily shipped all over

the world. It can be hauled on a flatbed truck, thereby

simplifying logistics and transportation. Figure 4 shows a

14 m long by 3 m wide by 4 m high partly assembled plant

module in transit.

Plants are heat integrated for high thermal effi-

ciency. Typical operating characteristics for a 330 Nm

3

/h

(0.3 MMSCFD) plant are:

Operating parameter

H

2

capacity, Nm

3

/h

330

H

2

purity, %

99.999

CO + CO

2

, ppm

<1

Pressure, barg

13.8

Natural gas /H

2

MM cal/Nm

3

H

2

(HHV)

4.4

Power, kW

60

Demineralized water, kg/h

550

These resultswere achieved in actual commercial oper-

ation over an extended time.

Advantages of the Hydroprime plants include:

•

Simple, quick site installation

•

Outdoor installation

•

Excellent accessibility for maintenance

•

Small footprint

The plants are standardized with fully automatic fail-

safe controls, allowing unattended operation with remote

start-up and 24/7monitoring. This enables quick response to

Fig. 3 —

Flow diagram of steammethane reforming (SMR) process.