FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

6 6

10

REDUCING THE COST OF HEAT TREATING ATMOSPHERES

Conserving utilities is the simplest, most practical way for heat

treaters to reduce costs and remain competitive.

Bud Weiland,

ERC International Inc., Cleveland

W

hile natural gas costs have been declining since

2014, bulk nitrogen costs have not followed the

same track. As nitrogen supply becomes an in-

creasing portion of the total cost to process metal prod-

ucts, technologies to generate nitrogen on-site become

viable. Many of the largest industrial gas suppliers will

install on-site air separation plants for producing nitrogen

for their larger consumers, but these arrangements typi-

cally come with high-commitment take-or-pay contracts.

For consumers in the middle range (e.g., 10-60,000 scfh

nitrogen requirements), bulk liquid nitrogen is the least

expensive among expensive options. By comparison, co-

generation technology, producing two utilities using one

process, has the potential to greatly reduce costs at facili-

ties that can fully use both utilities.

BENEFITS OF COGENERATION TECHNOLOGY

ERC International supplies cogeneration equipment

to manufacturing facilities that consume both nitrogen and

steam, with the largest market presence in the metals pro-

cessing industries. The fastest return on investment is seen

by facilities using delivered liquid nitrogen and plant steam.

There is also added value to facilities generating their own

endothermic gas, a carbon-intensive atmosphere used in

the heat treating industry. The typical ERC user is a metal

processor that has large heat treating furnaces, consumes ni-

trogen in the range of 10-60,000 scfh, and uses steam (or hot

water) for heating acid pickling tanks. For bright annealing

and annealing of medium carbon alloy steels, endothermic

gas is sometimes blended with nitrogen. All of these utilities

(nitrogen, steam, and the total supplies for the endothermic

generator) are delivered by one ERC cogeneration unit.

ECONOMIC BENEFIT

The economic benefit comes from replacing the cost

of nitrogen and endothermic gases with just the cost to

run the purification section of the cogenerator. The fuel to

run the steam section of the cogenerator (natural gas or

propane) is equal to the fuel being used to generate plant

steam and, thus, is cost neutral. The difference is that the

cogenerator products of combustion are carefully controlled

to be suitable for purification into a very good atmosphere

gas compared with conventional plant boilers that are just

venting their products of combustion. Users keep their

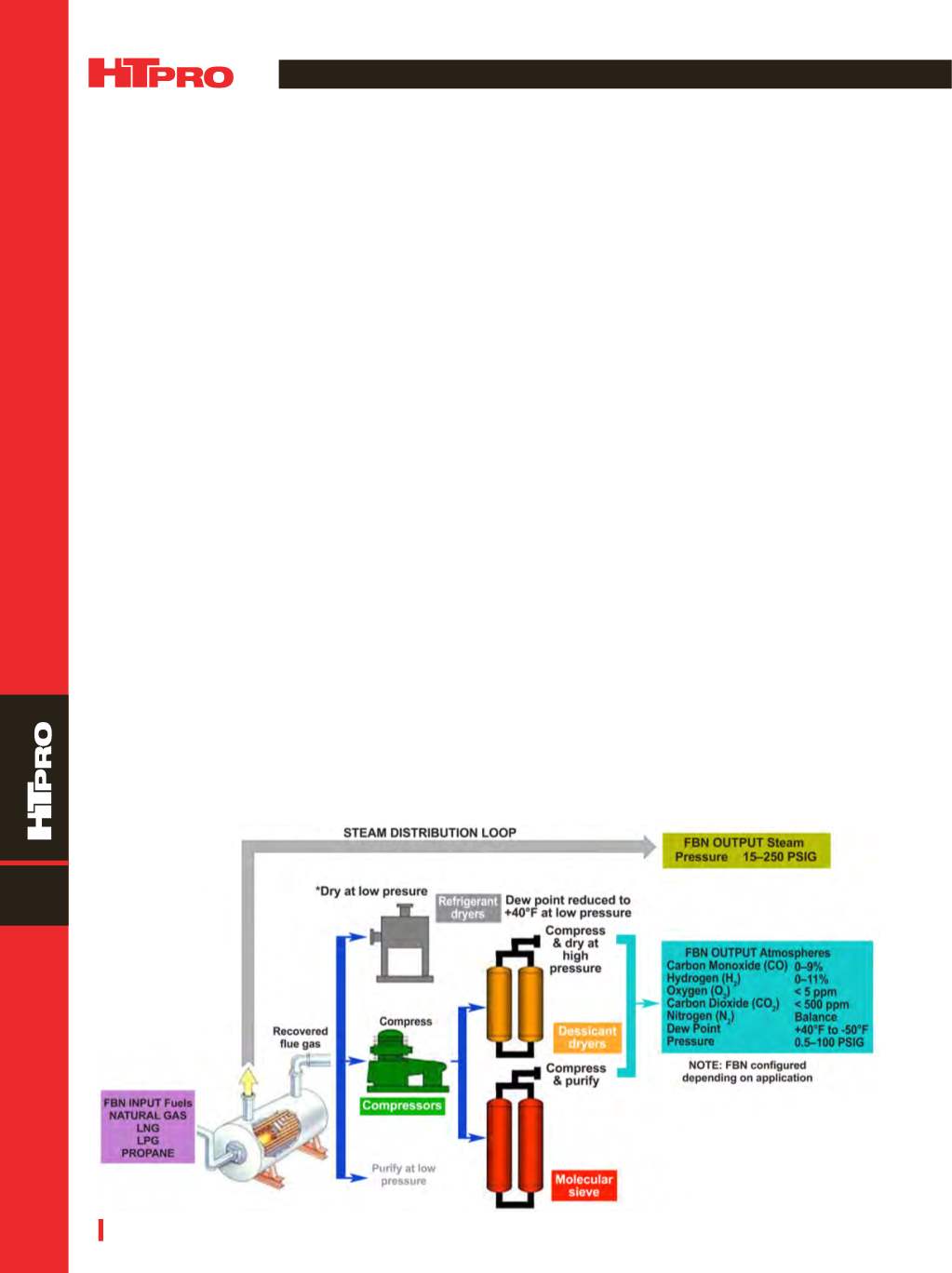

Schematic of ERC International fuel-based nitrogen cogeneration system.