FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

4 2

10

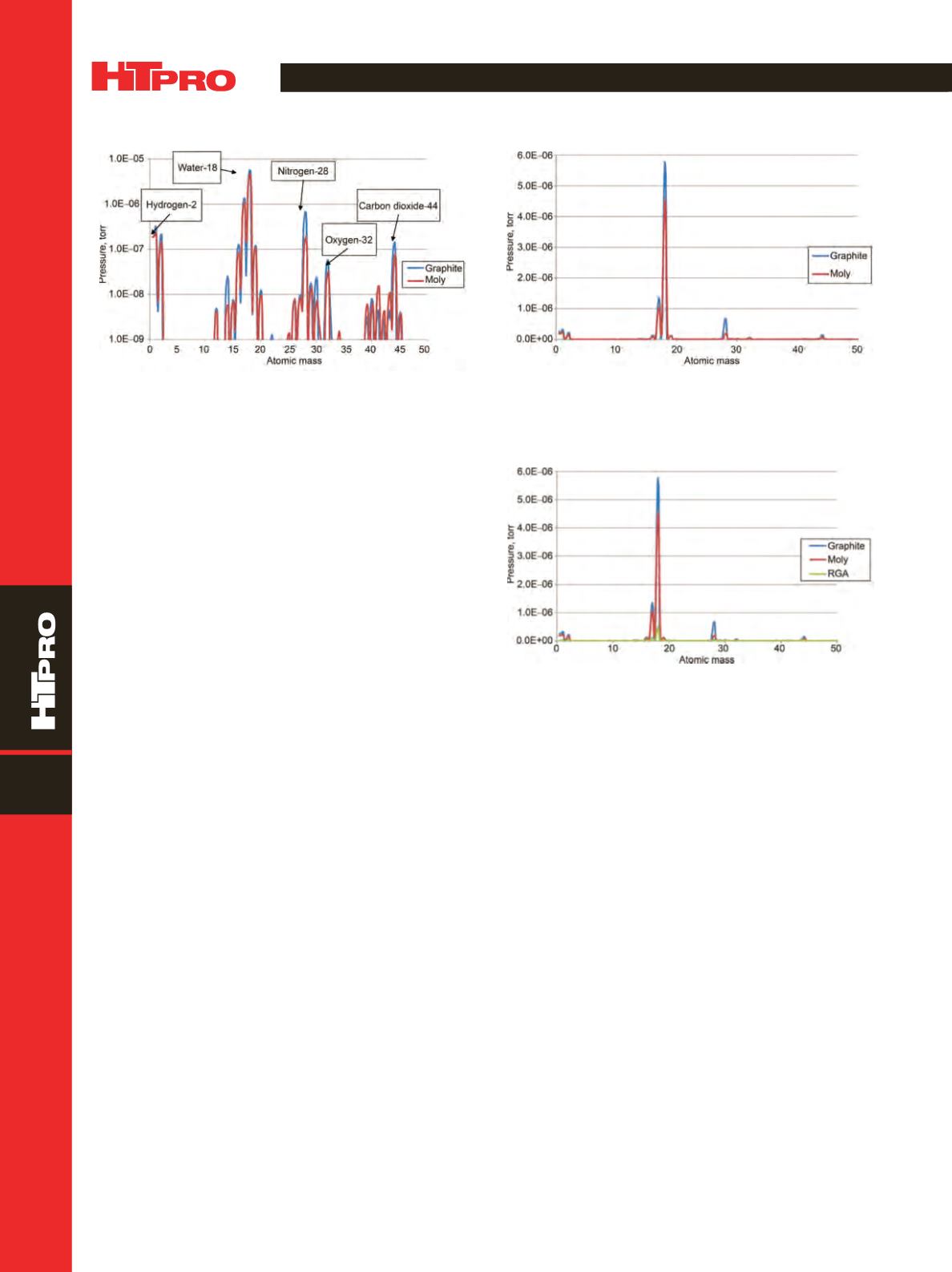

Fig. 8 —

Linear scale plot of residual gas analysis results in graph-

ite and all-metal (molybdenum) hot zones at ambient tempera-

ture and 5 x 10

−

5

torr.

Fig. 9 —

Linear scale plot of residual gas analysis results, includ-

ing traces of residual gases remaining in the residual gas analyzer

(RGA), for graphite and all-metal (molybdenum) hot zones at

ambient temperature and 5 x 10

−

5

torr.

all-metal design, and also to its retention of water vapor and

collection of air components when the furnace is open. In ad-

dition, the graphite carbon molecules contribute to the car-

bon dioxide residual gas. Figure 8 shows a linear RGA plot of

the above ambient temperature tests. Figure 9 includes trac-

es of residual gases that remained in the residual gas analyzer.

Residual gas trends with changes in vacuum and tem-

perature are shown in Fig. 10. Water, air, and carbon values

are higher in the graphite design.

Residual gases in the all-metal and graphite hot zones

when the furnaces are held at a temperature of 2200

°

F are

shown in Fig. 11. The graphite hot zone shows a signifi-

cantly larger number for water and air when held at this

temperature.

ANALYSIS OF RGA RESULTS

Results show that a molybdenum all-metal hot zone

should be used for processing materials that must meet crit-

ical surface contamination requirements. However, these

critical materials represent a very small portion (<10%) of all

the materials being processed in vacuum today.

To successfully minimize or eliminate surface contam-

ination in a furnace with a graphite hot zone, the following

conditions must apply:

•

Work must be clean

•

The furnace must have a proven low leak rate

•

The furnace must be able to achieve a low vacuum

initial pump down

•

The furnace must be baked out on a consistent

schedule to minimize internal contamination

Figure 12 shows an example of a critical material (tita-

nium bulkhead forgings) that can be processed in a graphite

hot zone furnace. A final acceptable surface condition can

be achieved in a graphite furnace that has been properly

prepared.

Fig. 7 —

Log scale plot of residual gas analysis results in graphite

and all-metal (molybdenum) hot zones at ambient temperature

and 5 x 10

−

5

torr.

Disadvantages of amolybdenumall-metal design com-

pared with a graphite design include:

•

Roughly 30% higher material cost than graphite

•

Less efficient and requires a larger, more expensive

power supply

•

About 50% lower projected service life

•

Embrittlement of the molybdenum as it ages (grain

growth)

•

Distortion including creep and buckling due to metal-

lization reactions

•

Difficult to repair compared with the graphite design

Differences in power requirements between molybde-

num and graphite hot zones are illustrated in Fig. 13, which

shows power consumedduringheatingof furnaces to2200

°

F

for the above test preparation and holding at temperature

for two hours. The graphite hot zone furnace is approxi-

mately 30% more efficient than the molybdenum hot zone

furnace, which represents a considerable savings on power

costs over the life of the hot zone.