A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

3 9

7

TECHNICAL SPOTLIGHT

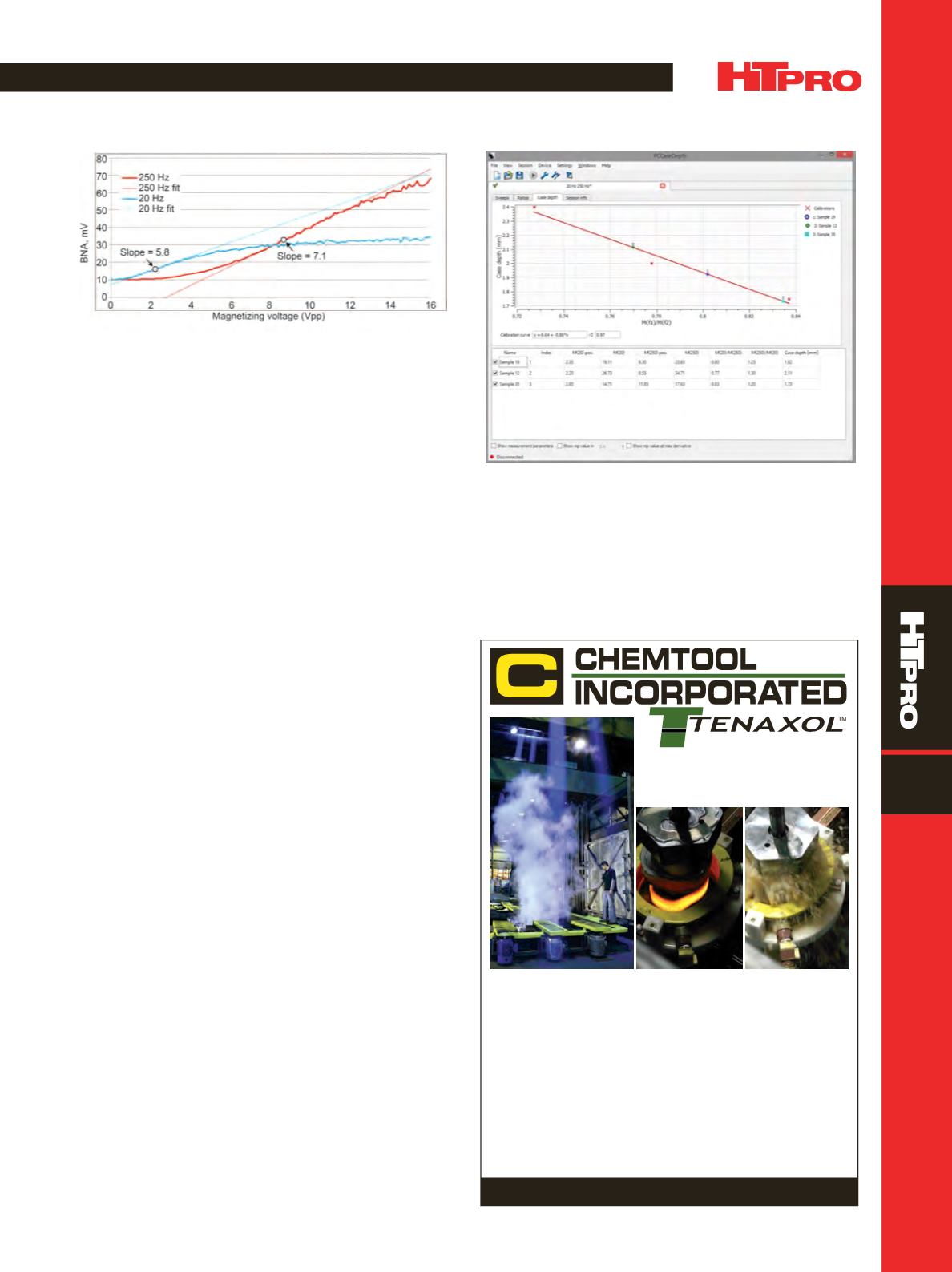

a given frequency. The slope

m

with respect to magnetiz-

ing voltage is calculated from this relationship to find the

maximum value,

m

max

.

This leaves a maximum MVS slope for both deep and

shallow frequency measurements. Calculating the ratio

of the two

m

max

values effectively corrects for the surface.

This value is correlated to case depth in a manner similar

to the way other NDT methods are correlated to properties

(Fig. 3).

Correlation typically involves generating a sample set

with known varying case depths and measuring them us-

ing the MVS slope-ratio method. Case depths are verified

via traditional methods (sectioning and metallography)

to establish the relationship between MVS slope ratio and

case depth. This enables associating MVS slope ratio val-

ues with specific case depths.

PROS AND CONS

Sectioning and metallography are used extensively

to measure case depth. This is labor intensive, slow, and

expensive. In contrast, the BN MNS slope-ratio method is

fast, inexpensive and easy. A measurement takes approx-

imately 30 seconds. Equipment is low maintenance and

requires no consumables, and once equipment and cor-

relation are set up, it requires minimal training to make

a measurement. In addition, this nondestructive method

saves labor used to section parts and eliminates scrap.

However, one disadvantage that the BN MVS slope-

ratio method has compared with traditional destructive

methods involves accuracy. It is common to have an r

2

≥

0.85 when correlating MVS slope ratio to case depth, but it

will not be accurate beyond tens of microns. As with other

NDT methods, accuracy varies on a case-by-case basis.

For more information:

James Thomas, American Stress

Technologies Inc., 540 Alpha Dr., Pittsburgh, PA 15238,

412.784.8400,

james.thomas@astresstech.com,

www. astresstech.com.

Fig. 2 —

Magnetizing voltage sweeps with fittedmaximum slopes.

Fig. 3 —

Case depth-measurement software including calibration

curve.

PIONEERS IN POLYMER QUENCHANTS... Tenaxol TM has been the leading brand in polymer quenchants for heat treaters. Chemtool Incorporated brings you a wide assortment of polymer products, plus a complete line of quenching oil lubricants and other quality offerings. Take a look at all we can do to help your operation get more productive...right here... www.tenaxol.com CHEM TOOL INCORPORATED 815-957-4140 Representatives Throughout North AmericaTenaxol AD5088 HTPro 2015

...and we have a lot more for you!