A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

4 1

9

FEATURE

RGA SCANS OF VACUUM FURNACE

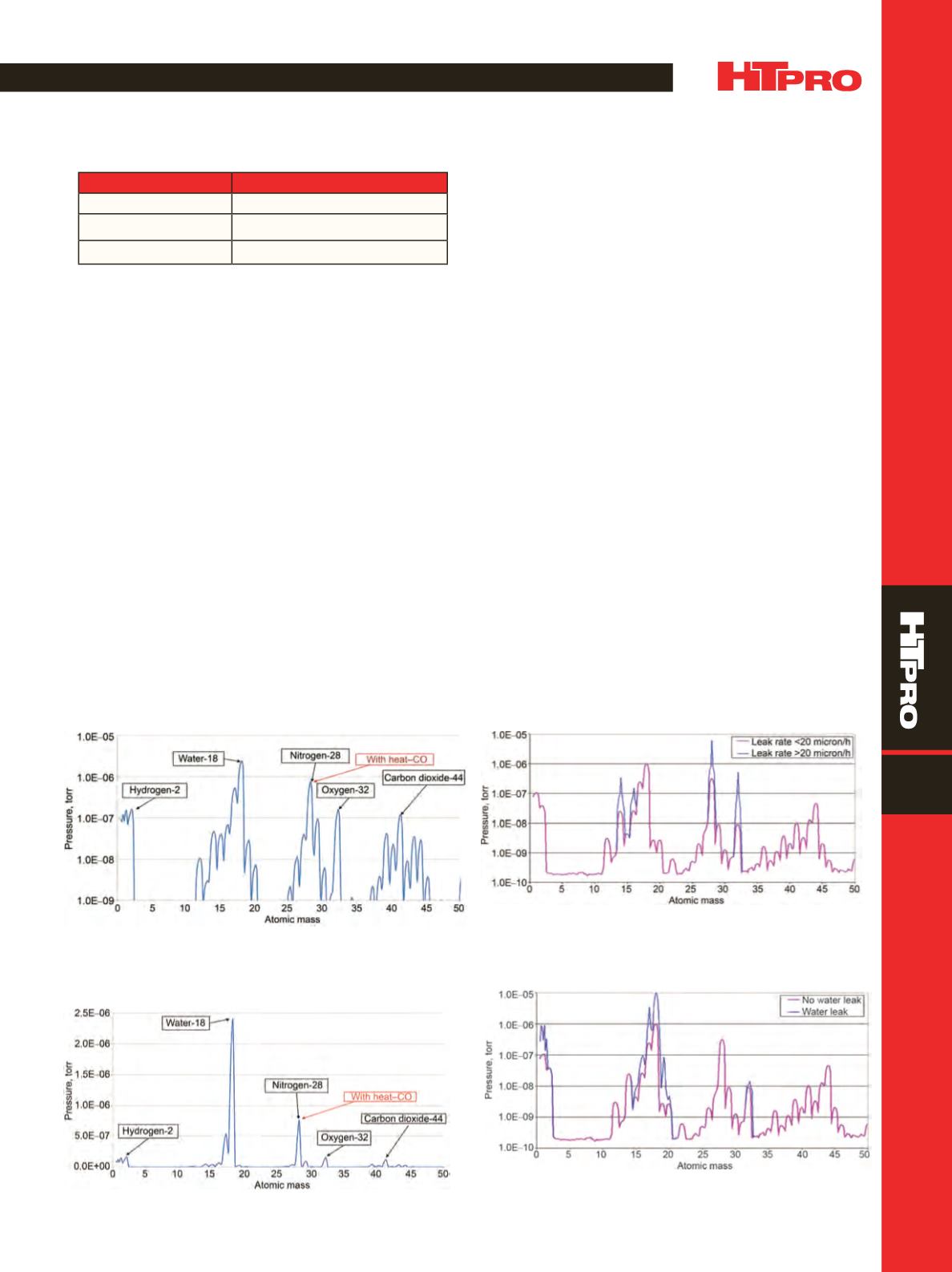

Logarithmic and linear plots of residual gases detect-

ed using RGA in a typical vacuum furnace pumped down to

the 10

−

4

torr range are shown in Figs. 3 and 4, respectively.

In Fig. 3, water has an atomic mass of 18 (hydrogen = 1

×

2

= 2, plus oxygen = 16 for a total of 18). The logarithmic plot

clearly shows residual gases compared to residual water va-

por, while the linear scale plot (Fig. 4) shows that water is the

major player.

TYPES OF VACUUM FURNACE LEAKS

Vacuum furnaces are prone to air and water leaks. An

RGA is used to help determine what type of leak is occur-

ring. Most involve some type of air leak due to bad seals and

joints. An air leak less than 20 microns/h is acceptable, while

a higher leak rate indicates a more serious problem. Figure 5

shows two RGA plots that reflect acceptable and unaccept-

able conditions. The atomic masses of nitrogen and oxygen

peak with a serious air leak.

Figure 6 is anRGA plot of a furnacewater leak. The high-

est peak is for the water residual component.

ALL-METAL VS. GRAPHITE HOT ZONES

Many vacuum furnace processes require a very deep

vacuum and minimal residual carbon gas to prevent con-

tamination of the final product surface. Identical laboratory

furnaces with 10-in. diameter by 18-in. long hot zones were

used to determine relative residual gases remaining in the

furnaces. One furnace had a graphite-insulated hot zone

with graphite elements, and the other had an all-metal mo-

lybdenum/stainless steel shielded design withmolybdenum

elements. The furnaces had identical pumping systems us-

ing Varian 8-in. diffusion pumps.

Prior to residual gas analysis, both furnaces were pre-

pared as follows:

1. Bake out at 2250°F for 2 h and vacuum cool to <125°F

2. Open furnace door for 5 min

3. Pump down to 5 x 10

−

5

torr

4. Ramp up at 20°F/min to 2200°F

5. Hold for 1 h

Figure 7 shows a log scale plot of ambient temperature

residual gas analysis results for both furnaces. Results indi-

cate that air components and carbon are more prevalent in

the graphite-insulated furnace. This is expected due to the

higher surface area of the graphite felt material than the

Major gas loads present inhighvacuumare shownhere:

Pressure, torr

Major gas load

10

−3

Water vapor (75-95%)

10

−7

H

2

O, CO, CO

2

10

−10

CO, H

2

Fig. 3 —

Residual gas analysis log scale plot of residual gases.

Fig. 4 —

Residual gas analysis linear scale plot of residual gases.

Fig. 5 —

Residual gas analysis for a furnace with an acceptable air

leak rate and serious leak rate.

Fig. 6 —

Residual gas analysis for a furnace with and without a

water leak.