CASE STUDY

iTSSe

TSS

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 5

4 1

iTSSe

TSS

9

REVIEW AR ICLE

microstructure of nanocomposite coatings manufactured by

conventional thermal spray processes as well as modern pro-

cesses such as cold spray, suspension, and SPTS. Prominent

nanocomposite materials deposited by thermal spray are as-

sessed in the

Nanocomposite coatings

section, with emphasis

on process-dependent phase transformations and their cor-

relations with nano/microstructure and coating properties.

The properties and applications of selected nanocomposite

coatings with a view towards future uses are presented in the

Properties and potential applications

section.

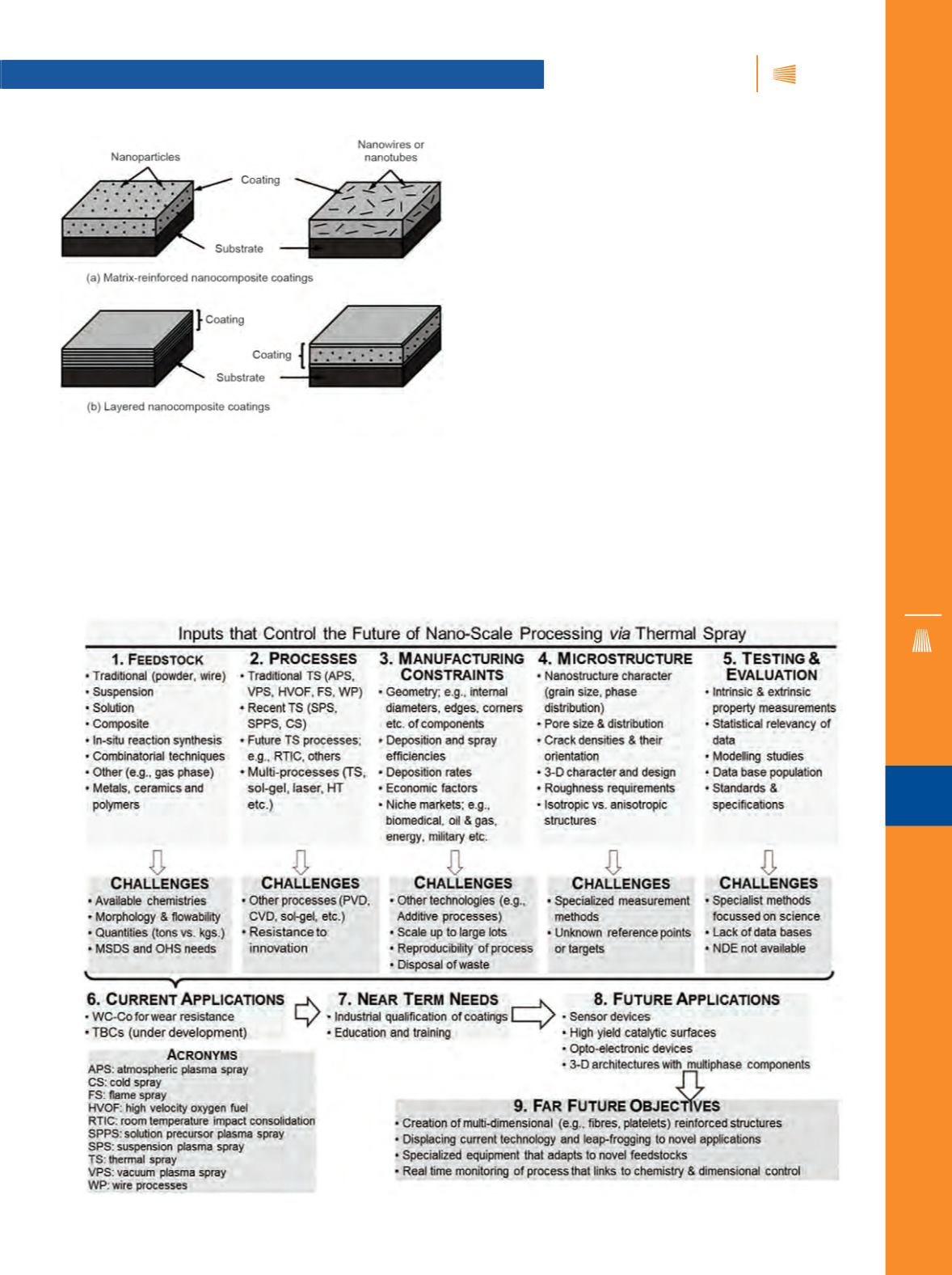

CHALLENGES AND OUTLOOK

Thermal spray can be segmented into five distinct group-

ings as shown in Fig. 40. The sequence is intended to be logi-

cal—thermal spray starts with an appropriate feedstock and

finishes with testing and evaluation for quality control purpos-

es before being implemented towards specific applications as

indicated in Box 6.

Nanostructured coatings exist in some microstructural

form for the majority of thermal spray coatings, necessitat-

ed by the rapid solidification process

[52,338]

. Thus, microstruc-

tural artifacts such as splat sizes, porosity, cracks, phase

Fig. 6 —

Schematics of nanocomposite coatings: (a) matrix-

reinforced, and (b) multi-layered.

Fig. 40 —

Input criteria that determine the outcomes for nanoscale materials manufactured by thermal spray methods.

powder, wire, or liquid form. (A section of this review is dedi-

cated to their production and characteristics.)

The

Thermal spray deposition: Process and microstruc-

ture

section highlights the formation mechanisms and nano/