iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

3 8

iTSSe

TSS

6

BOOK PREVIEW

COMING SOON—HIGH PRESSURE

COLD SPRAY: PRINCIPLES AND

APPLICATIONS*

ASM International will publish a new technical book on high pressure cold spray in late 2015.

Here we preview this exciting new edition.

T

he new technical book on

High Pressure Cold Spray:

Principles and Applications

is a highly practical and use-

ful reference book that presents an in-depth look at the

high pressure cold spray process, and also describes applica-

tions in various industries. The book, to be published later this

year, is expected to be a trusted, “go-to” resource that is both

comprehensive and technically advanced.

Cold spray continues to be the fastest developing spray

technology of the past decade, and a significant number of sci-

entists, engineers, and technologists are joining the cold spray

community around the globe. The technology is relatively

young and work is being simultaneously pursued in universi-

ties, research centers, and many high-tech industries. As this

novel technology spreads quickly into many new application

areas, there is an urgent need for authoritative information.

The new book is expected to address this need and be

indispensable to universities, libraries, and those involved in

thermal spray. This comprehensive volume presents baseline

information on design and modeling, materials science of en-

gineered coatings, and specific applications in various high-

tech industries, and will also be a hands-on resource for cold

spray operators.

The new technical bookwas authored by a group of glob-

al cold spray experts and is edited by Charlie Kay and Jegan

Karthikeyan of ASB Industries, Barberton, Ohio, with an intro-

duction by Mark Smith of Sandia National Labs. Selected top-

ics include:

•

Theory, modeling and fundamental science by Thomas

Klassen and his group at Hamburg University, Germany

•

Cold spray equipment by Peter Richter Sr. of Impact

Innovations, Germany

•

Mechanical and metallurgical characterization of coat-

ings by Dheepa Srinivasan of General Electric, India

•

Applications of cold spray coatings in various industries,

including Nuclear (Eric Irissou, et al., NRC, Canada),

Defense (Tim Eden, Penn State University, College Park),

Automobile (Changhee Lee and Jaeick Kim, Hanyang

University, South Korea), Aerospace, Oil & Gas, and

Power Generation (Eklavya Calla and Dheepa Srinivasan,

General Electric, India)

Various applications of cold spray processes includ-

ing protective coating production, development of perfor-

mance-enhancing layers, repair and refurbishing of parts, and

NNS fabrication are elaborated in each industry with illustra-

tive case studies by cold sprayers actively involved in the field.

The book is a must-have resource for anyone involved in cold

spray technology, from coating design and development to

performance of coatings and coated parts in both the labora-

tory and industrial environments.

ABOUT THE EDITORS

Charles M. Kay, vice president,

ASB Industries,

Barberton, Ohio

Charles Kay has been with

ASB Industries for over 29 years,

which focuses on expanding the

reach of thermal spray technolo-

gy in new areas. He specializes in

identifying new application areas in various industries such

as steel, paper, power generation, and also catering to their

needs. He has co-authored many technical articles on cold

spray technology published in various peer-reviewed jour-

nals and conference proceedings. He has served as presi-

dent of the Thermal Spray Society and is an active member

of various TSS Committees.

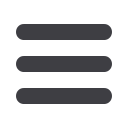

The high-pressure cold spray (HPCS) process uses a high-pres-

sure gas heater and a high-pressure powder feeder to inject the

spray powder upstream of the nozzle throat. The process gas is

initially heated in order to increase the flow velocity of the gas

in the spray nozzle and thus increase spray particle velocities.

Although the gas may start out at moderately high temperatures,

it cools very rapidly as it expands in the long diverging section

of the spray gun nozzle and the spray particle temperatures

therefore remain well below the melting point.

*Working title

Kay