EDITORIAL

iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

4 0

iTSSe

TSS

8

REVIEW RTICLE

NANOCOMPOSITE THERMAL SPRAY REVIEW

Jo Ann Gan

Christopher C. Berndt, FASM*

The following is an excerpt of the full review article, “Nanocom-

posite coatings: Thermal spray processing, microstructure and

performance,” from

International Materials Reviews,

Vol 60

(4), May 2015. The full 50-page review, with 394 references, can

be found at

maneyonline.com/loi/imrthrough mid-June. Copy-

right 2015 Institute of Materials, Minerals and Mining, and ASM

International.

N

anomaterial and nanocomposite processing have

made advances since the 1990s. The growth and op-

portunities this technology offers is based on research

and development funding trends, science citation index (SCI)

publications, and patent applications. This article reviews the

current state of thermal spray nanocomposite coating de-

velopment, while types of commercially available nanocom-

posite thermal spray feedstock materials, as well as those in

development, are assessed.

Thermal spray approaches to depositing nanocomposite

coatings including conventional plasma spray and high veloc-

ity oxygen fuel (HVOF) processes are discussed, as are more

recently developed processes of cold spray, suspension ther-

mal spray (STS), and solution precursor thermal spray (SPTS).

These processes are assessed in relation to their deposition

mechanisms and the specific nanocomposite materials used

for each technique. The unique microstructure of coatings

deposited by each method is highlighted in relation to pro-

cess and compositional control. The exceptional attributes

of nanocomposite coatings, such as mechanical strength and

toughness, wear resistance, and thermophysical and elec-

trical properties are also highlighted with regard to specific

applications.

NANOMATERIAL PROPERTIES

Nanomaterials demonstrate unique optical

[13,14]

, ther-

mal

[15,16]

, mechanical

[17,18]

, electrical

[19,20]

, and magnetic

[21,22]

properties that are not exhibited by their bulk counterparts.

The attributes of nanostructured materials that are size-de-

pendent arise from surface and grain boundary effects due to

a significant increase of surface-to-volume ratio and quantum

effects due to confinement of electron movement; changes in

the electronic structure and interatomic relation; and defect

presence

[12,23]

. Nanomaterials are found in many practical ap-

plications ranging from electronics to aerospace.

Two basic approaches to producing nanostructured

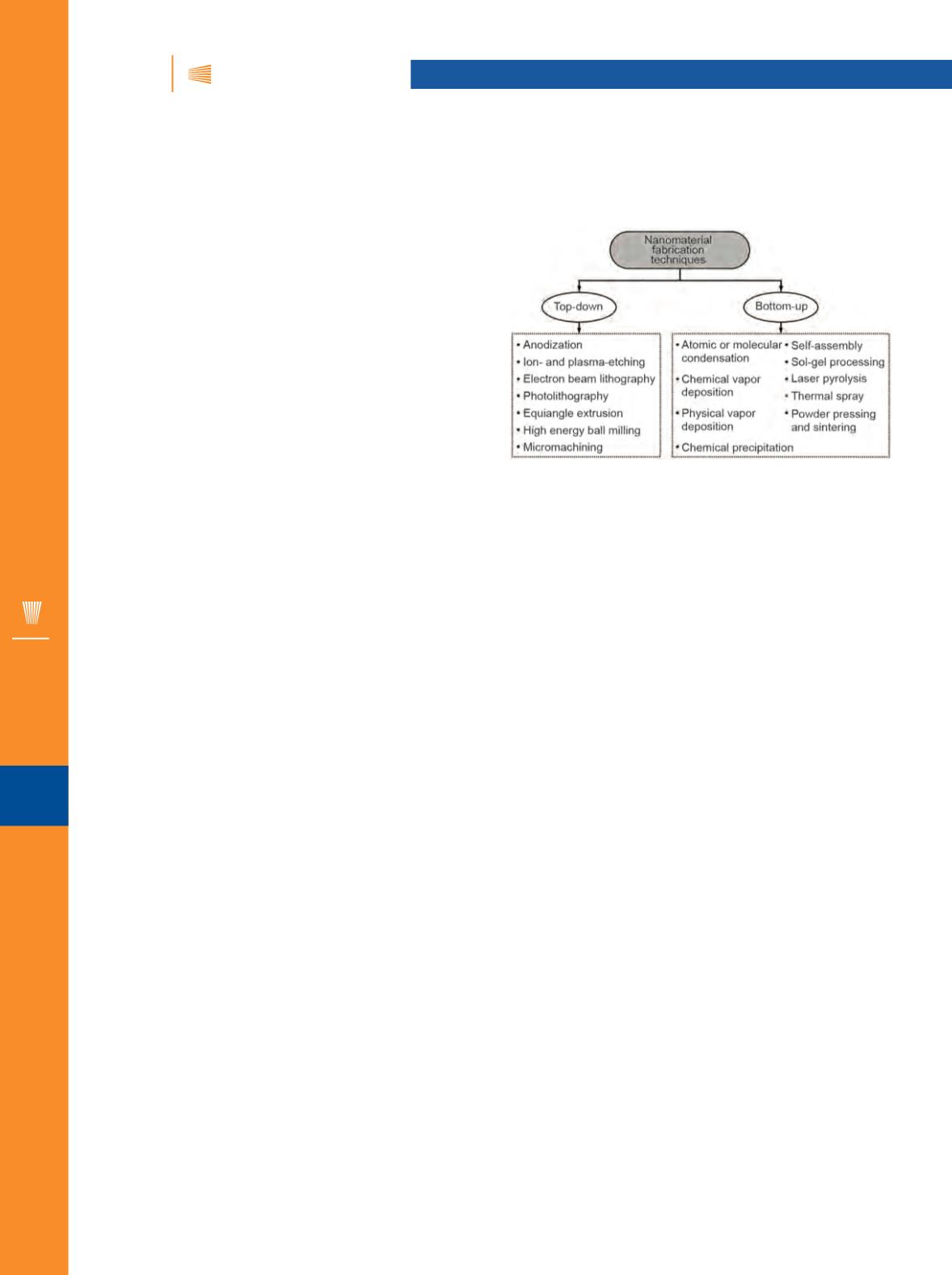

materials include top-down and bottom-up methods (Fig. 3).

The top-down approach involves the breakdown of a bulk

material structure to reduce crystal size to sub-micrometer or

nanoscale. The bottom-up approach involves processing or

building up a material from the atomic scale or nanoclusters

to retain the original nanoscale structural units.

The focus here is on thermal spray to deposit nanocom-

posites—a bottom-up approach. It might be argued that the

impact process during thermal spray coating formation causes

fragmentation of micrometer-sized particles to the nanoscale,

which is a top-down approach. However, because this is not

the preferred formation process that would retain a lamellar

structure, the bottom-up approach is considered dominant.

NANOCOMPOSITE COATING ADVANTAGES

Despite their advantages, bulk nanocomposites can be

expensive to produce due to nanomaterial production costs

and technical limitations in preserving a nanostructure in a

consolidated product due to excessive grain growth

[40]

. Nano-

composite coatings use lesser amounts of nanostructuredma-

terials because they are quite thin—several micrometers up to

a millimeter depending on the deposition technique, and can

potentially cover large areas. Therefore, nanocomposite coat-

ings offer an alternative that takes advantage of the many re-

markable properties of nanomaterials without the production

costs of bulk nanocomposites. There are two types of nano-

composite coatings: matrix-reinforced, where the reinforcing

phase is within nanoscale, and layered coatings, where the

thickness of individual layers arewithin nanoscale dimensions

(Fig. 6).

Thermal spray processes and nanocomposites have al-

ready been reviewed independently; therefore nanocompos-

ite coatings deposited by thermal spray processes in relation

to their processing, microstructure, and performance will be

reviewed here. Feedstock materials for thermal spray come in

*Member of ASM International and Thermal Spray Society

Fig. 3 —

The top-down and bottom-up approaches for nanomate-

rials fabrication.