iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

4 6

iTSSe

TSS

14

JTST

HIGHLIGHTS

The

Journal of Thermal Spray Technolo-

gy

(

JTST

), the official journal of the ASM

Thermal Spray Society, publishes con-

tributions on all aspects—fundamental

and practical—of thermal spray science,

including processes, feedstock manu-

facture, testing, and characterization.

As the primary vehicle for thermal spray

information transfer, its mission is to syn-

ergize the rapidly advancing thermal spray industry and relat-

ed industries by presenting research and development efforts

leading to advancements in implementable engineering appli-

cations of the technology. Articles from the February and April

issues, as selected by

JTST

Editor-in-Chief Christian Moreau,

are highlighted here. In addition to the print publication,

JTST

is available online through

springerlink.com. For more infor-

mation, visit

asminternational.org/tss.

MICROSTRUCTURE OF KINETIC

SPRAY COATINGS: A REVIEW

Changhee Lee and Jaeick Kim

Kinetic spray is used in various industries such as au-

tomotive, aviation, and defense because it can produce a

high-performing coating layer. However, because the prop-

erties of the kinetic-sprayed coating layer are significantly

affected by deposited microstructures, the deposited micro-

structures shouldbecontrolledtoacquireanadvancedcoating

layer and a deep understanding of microstructural evolution

must be achieved before controlling the coating layer’s micro-

structure. An overview of contents related to the microstruc-

ture of kinetic-spray deposition is offered. The most powerful

influencing factors in microstructural evolution of the kinet-

ic-spray coating layer are instant generation of thermal energy

and high-strain and high-strain-rate plastic deformation at the

moment of particle impact. A high-density coating layer with

low porosity can be produced, although some micro-cracks

are occasionally induced at the interparticle boundary or

at the particles’ inner region. Also, a microstructure which is

distinct from the inner particle region is created in the vicinity

of the particle-particle or particle-substrate interface region.

However, almost no crystal phase transformation or chemical

reaction is induced since the deposited particles are not heat-

ed directly by a thermal energy source.

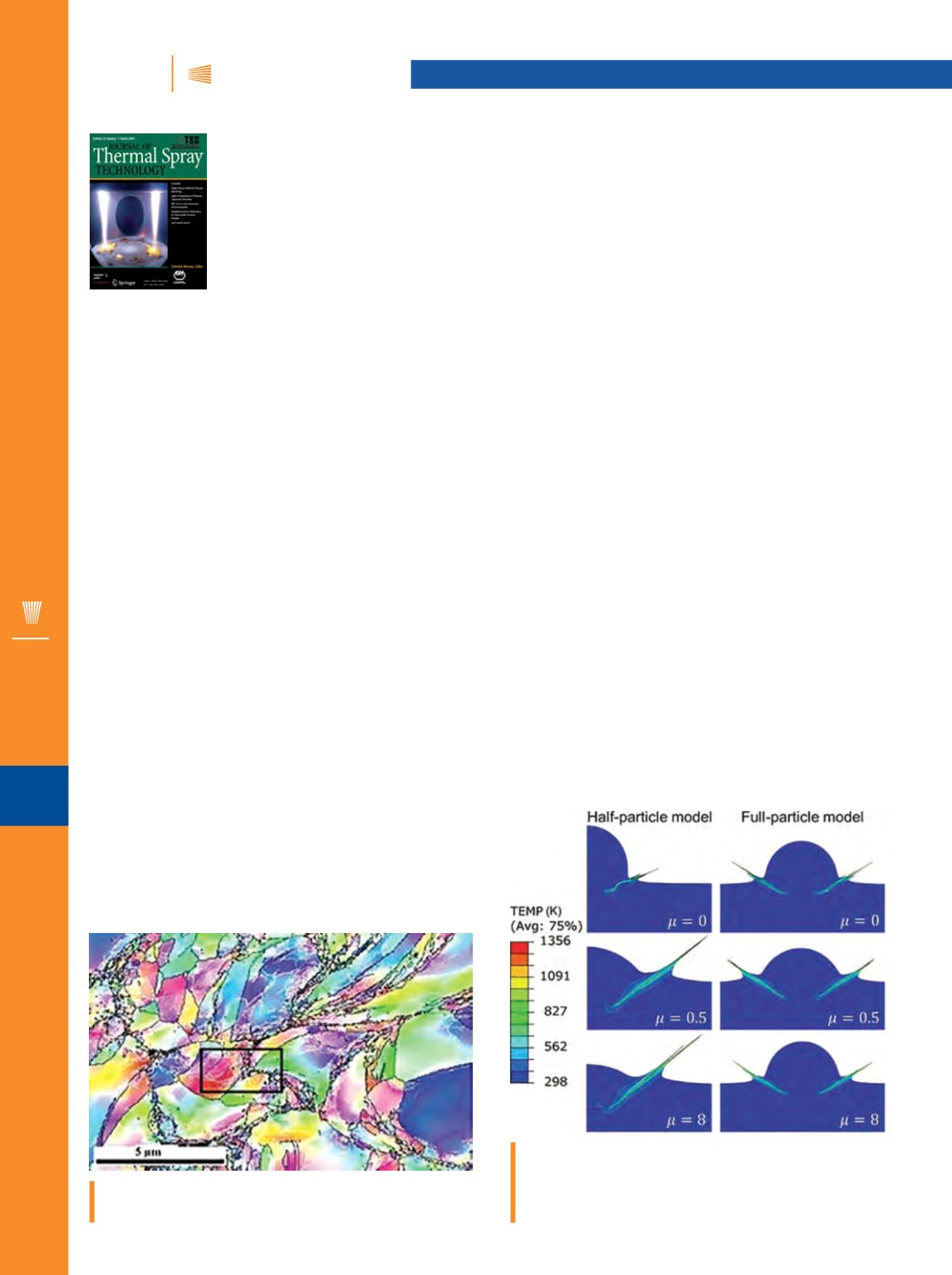

THE EFFECTS OF CONTACT CONDITIONS

ON THE ONSET OF SHEAR INSTABILITY

IN COLD-SPRAY

Fanchao Meng, Huseyin Aydin,

Stephen Yue, and Jun Song

Using ABAQUS/Explicit, the effects of contact conditions

between the particle and substrate, including tangential fric-

tion, normal constraint, and contact geometry on the plastic

deformation during the cold spray process are studied. The

onset of shear instability, an event often used to indicate the

establishment of bonding, was found to be very sensitive to

the choice of contact conditions. This suggests that the onset

of shear instability does not serve as an accurate means to

identify the plasticity threshold responsible for bonding. On

the other hand, it is demonstrated that the evolution of the

overall equivalent plastic strain (PEEQ) and the overall von

Mises stress, being linearly proportional toeachother, areboth

independent of contact conditions. Furthermore, it is shown

that an energy value, defined as the product of the PEEQ and

the von Mises stress integrated over all particle elements, can

quantitatively represent the energy dissipated via plastic de-

formation while being independent of contact conditions. The

PEEQ and associated energy value as defined may provide ro-

bust tools to assess the plasticity and the consequent bonding

during cold spray.

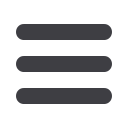

EBSD characterization of the as-sprayed Ni coating: (a) Euler

angle map.

Deformed particle/substrate configurations and temperature

contours at the onset of shear instability in a half-particle model

and full-particle model for three representative friction coeffi-

cients

μ

= 0, 0.5, and 8.