iTSSe

TSS

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

4 8

iTSSe

TSS

16

JTST

HIGHLIGHTS

EFFICIENT LARGE-SCALE COATING

MICROSTRUCTURE FORMATION

USING REALISTIC CFD MODELS

Thomas Wiederkehr and Heinrich Müller

To understand the physical effects during thermal spray

coating layers formation and the deduction of the macro-

scopic properties of a coating, microstructure modeling and

simulation techniques play an important role. A coupled sim-

ulation framework consisting of a detailed, CFD-based single

splat simulation, and a large-scale coating build-up simulation

capable of computing large-scale, 3D, porous microstructures

by sequential drop impingement of more than 10,000 individ-

ual particles on multicore workstation hardware is presented.

Due to the geometry-based coupling of the two simulations,

the deformation, cooling, and solidification of every particle

is sensitive to the hit surface area and thereby pores develop

naturally in the model. The single splat simulation uses the

highly parallel Lattice-Boltzmannmethod, which is well suited

for GPU acceleration. In order to save splat calculations, coat-

ing simulation includes a database-driven approach that reus-

es already computed splats for similar underground shapes at

the randomly chosen impact sites. For a fast database search,

three different methods of efficient pre-selection of candi-

dates are described and compared against each other.

technique. Coatings were produced with a laser power of

2.5 kW, powder-laser spot trailing by 5 s. Coatings were ana-

lyzed for microstructures, microhardness, composition, and

bio-corrosion using SEM-EDS, XRD, hardness tester, and a

Metrohm PGSTAT101 machine. SEM images indicate least

pores and crack-free coating with dark-spots of Ti-HAP for the

20 wt%, HAP as opposed to the 80 wt%, HAP coating, which

was solid, porous, and finely cracked and had semi-melted

Ti-HAP particles. EDS mappings show high content of HAP for

the 80wt%, HAP coating. The diffraction patterns were similar,

even though the Ti-HAP peak was broader in the 80 wt%, HAP

coating and the HAP intensities were lower for this coating ex-

cept for the (004) peak. Hardness values taken at the interface

inferred that the 80wt%, HAP coatingwas least bonded. It was

possible to conclude that when this phase material increased

the hardness dropped considerably. Bio-corrosion tests indi-

cated that the presence of HAP in coatings leads to a kinetical-

ly active coating as opposed to pure titanium coating.

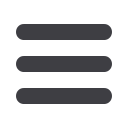

Illustration of the 19 directions e

α

of the D3Q19 lattice model.

MICROSTRUCTURAL AND MECHANICAL

EVALUATION OF LASER-ASSISTED COLD

SPRAYED BIO-CERAMIC COATINGS:

POTENTIAL USE FOR BIOMEDICAL

APPLICATIONS

Monnamme Tlotleng, Esther Akinlabi, Mukul Shukla,

and Sisa Pityana

Bio-composite coatings of 20 wt%, HAP and 80 wt%,

HAP were synthesized on Ti-6Al-4V substrates using LACS

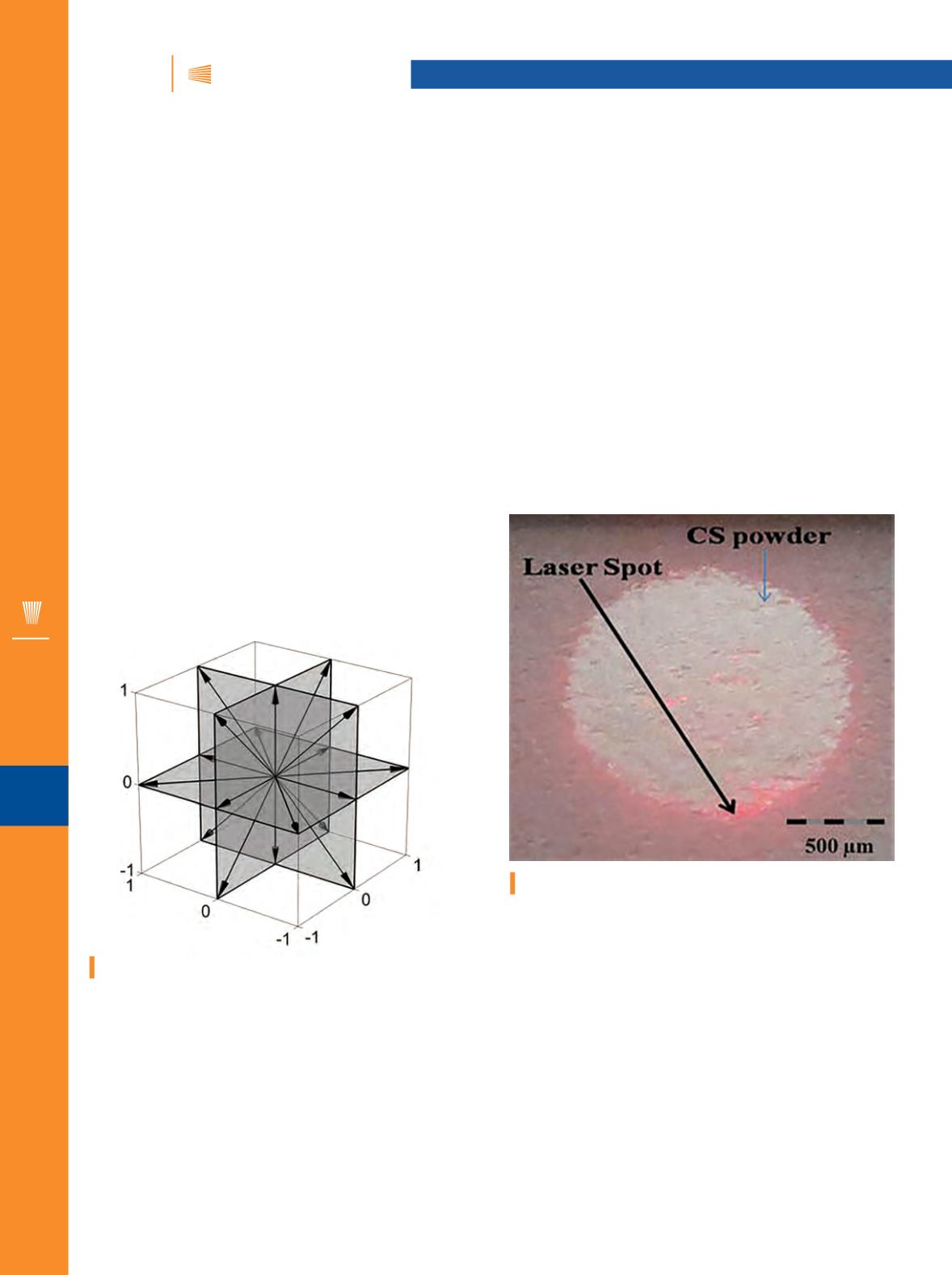

Optimized powder-laser spot interaction.

COMPOSITIONAL DEVELOPMENT AS A

FUNCTION OF SPRAY DISTANCE IN

UNSHROUDED/SHROUDED PLASMA-

SPRAYED CR

3

C

2

-NICR COATINGS

S. Matthews

Thermal spray of Cr

3

C

2

-NiCr composites generates vary-

ing degrees of carbide dissolution into the Ni binder. During

high-temperature exposure, the carbide dissolution zones

precipitate high concentrations of small carbides that devel-

op into finely structured networks. This raises the possibility

of producing unique tailored carbide composite structures

through generation of controlled carbide dissolution and

appropriate heat treatment. The first step in this process is