32

ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

T

he Pittsburgh Reduction Co. signed the first

industrial contract to take electricity from

hydropower at Niagara Falls, N.Y., in 1893.

A new aluminum processing plant was built there,

which became operational in 1895. A second plant

was constructed at the Falls in 1896, followed by a

third plant—with its own electric power facility—

in 1906. With steadily increasing production ca-

pacity and decreasing costs, the Pittsburgh

Reduction Co. expanded rapidly throughout the

1890s. Production reached five million pounds in

1900, while the price decreased from 78 cents/lb

for ingots in 1893 to 33 cents/lb in 1900.

The need for sheet, plate, wire, and other prod-

uct forms meant installing equipment and hiring

specialists to fabricate these products at the plant

in New Kensington, Pa. When all the alu-

minum chemical reduction operations were

moved to Niagara Falls under Charles Martin

Hall, Arthur Vining Davis was put in charge

of working aluminum into other products.

This first decade of operations saw small an-

nual losses in the early years and very modest

profits at the end of the decade when pretax

earnings reached $322,000.

At this critical time in the aluminumbusi-

ness, the Pittsburgh Reduction Co. lost its dy-

namic leader, Alfred E. Hunt. With his

enthusiasm for the military, he led a company

of men into the Spanish AmericanWar. He was

posted to Puerto Rico where he contracted a

tropical illness that took his life shortly after his

return to the United States. RichardMellon was ap-

pointed president to succeed Hunt, but day-to-day

management tasks fell to Davis. The company con-

tinued to be controlled by Hall, Davis, the Mellons,

and a small group of original investors. Hunt’s fam-

ily inherited his shares in the company and his son

Roy joined the company upon college graduation.

Roy became a key manager under Davis and played

a significant role in the company’s fortunes.

Early aluminum applications

Aluminum production increased from five mil-

lion pounds in 1900 to 35 million in 1909. A major

application during this era was kitchenware, for

which aluminum was best known by the American

public. The Pittsburgh Reduction Co. acquired a

kitchenware producer in 1901 when it went bank-

rupt due to owing a substantial bill for aluminum.

This acquisition brought the company a pair of col-

lege students who had been selling pots and pans

door-to-door with great success. A new company

was organized to improve the quality and expand

this effort. The resulting kitchenware became well

known under the WearEver Cookware brand and

continues to be widely sold today.

One of aluminum’s early industrial uses was for

cable to transmit high-voltage electric current over

long distances. However, aluminum was not strong

enough to carry its weight from tower to tower. The

Pittsburgh Reduction Co. resolved this by adding a

steel wire to the center of the cable. After 1910, a

growing demand for aluminum came from the

newly developing automobile industry. It was easier

to manufacture customized bodies from ductile alu-

minum than steel. Yet this application, as with so

many others, turned out to be short-lived because

mass production required the lowest-cost material,

steel. The market for aluminum cast parts was a

substantial component of the early automobile in-

dustry, and a new casting process was developed in

which molten aluminum was poured into water-

cooled steel molds rather than into sand molds.

Raw materials

Expanded aluminum production after 1900 re-

quired the Pittsburgh Reduction Co. to seek both

Metallurgy Lane,

authored by

ASM life member

Charles R. Simcoe

,

is a yearlong series

dedicated to the early

history of the U.S. metals

and materials industries

along with key

milestones and

developments.

Aluminum: The Light Metal—Part II

The cost of electric power is the biggest expense involved in aluminum production.

Proximity to economical power sources determined the location of major aluminum

reduction plants.

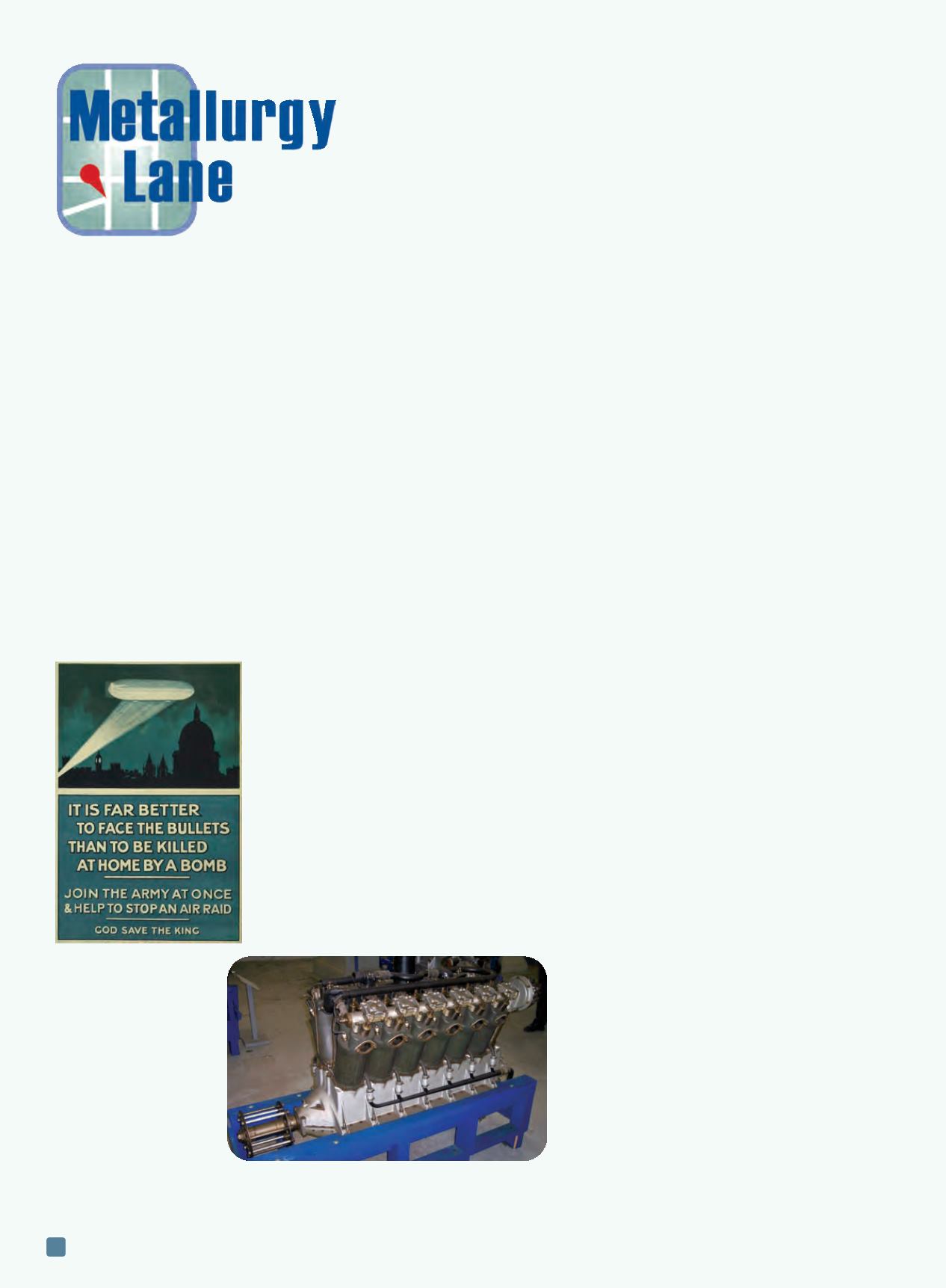

Liberty L-12 aircraft engine. Cast aluminum was used

for its light weight. Courtesy of Stahlkocher/Wikimedia

Commons.

British WWI military

recruiting poster

features a Zeppelin

above London at night.

German Zeppelins

represent the first major

use of the precipitation

hardening alloy

Duralumin. Public

domain image.