33

ADVANCED MATERIALS & PROCESSES •

OCTOBER 2014

lower-cost raw materials and more economical elec-

trical power. In addition, this search for backward in-

tegration was a necessary part of the company plan to

exclude competition after the Hall patents expired in

1909. Electrical power was the costliest ingredient in

aluminum production. By 1909, the company (re-

named the Aluminum Company of America, or

Alcoa for short) had secured water rights along the

Little Tennessee River. They built dams, power

plants, and a smelter around a small settlement they

called Alcoa, Tenn.

Because the known reserves of domestic bauxite

were inadequate, Alcoa searched overseas for all fu-

ture supplies. Their largest investment was in the

British and Dutch Guineas where vast reserves were

located. The company also began producing a syn-

thetic cryolite to replace the natural mineral, as the

only available source of natural cryolite was in Green-

land. The cryolite was used to dissolve alumina for

the electrolytic processing to make aluminummetal.

World War I

Alcoa had fully integrated from mine to alu-

minum metal by the time of increased demand after

1910, especially with the start of World War I. They

had also moved forward into production of many fin-

ished products. Alcoa became a major force in the

worldwide aluminum industry. Although there were

a number of competitors overseas, especially in

France and Switzerland, Alcoa was protected by high

tariffs during the prewar years and by wartime needs

after 1915. The company sold its inventory of alu-

minum to the European powers allied against Ger-

many in 1915 and 1916. Production was then

purchased for U.S. defense use in the remaining years

of the war. The bulk of all aluminum sold during this

period went into munitions. As a powder, it was

mixed with ammonium nitrate to form a high explo-

sive. Other defense applications helped promote

postwar uses for the metal, for example, specification

of aluminum alloys for the Liberty engine used in

most American aircraft built during the war.

Alcoa achieved pretax earnings of $4 to $6 million

during each year between 1909, when the patents ex-

pired, and 1914. Earnings increased to $9 million in

1915, and then $25 million in 1916, $20 million in

1917, and $15 million in 1918. By 1919, Alcoa had cor-

porate equity of $100 million, mainly from retained

earnings. Of this equity, $60 million was earned during

WWI. Alcoa’s strong position in later years was a di-

rect result of the enormous profits from the war.

Ongoing research

Numerous technical problems arose during the

war years for which Alcoa was unprepared. Castings

for the Liberty aircraft motor, engine pistons, and

many other applications posed special problems

throughout the aluminum foundry industry. The pri-

mary embarrassment for the company was its inabil-

ity to produce the new German alloy called

Duralumin. This alloy, which could be hardened by

precipitation of a second phase, was used on all Ger-

man Zeppelins built during the war. It was also being

manufactured and used by France and Great Britain

in limited aircraft applications.

The delay in undertaking research and develop-

ment was due to Hall’s reluctance to employ person-

nel trained in science, as this was his field of expertise

and he jealously guarded it. After Hall died of

leukemia in 1914 at the age of 51, management could

now remedy this important deficiency. The man they

hired was Francis C. Frary. He graduated in chem-

istry from the University of Minnesota and attended

the University of Berlin for two years before receiving

his doctorate from Minnesota. He taught there for

several years and then moved on to perform research

in industry. During the war, he went into the army to

work in chemical warfare and joined Alcoa in 1919

as director of research. Frary continued to head re-

search at Alcoa for the next 33 years, where he built

one of the best laboratories in the country. In 1946,

he received the Perkins Medal from the American

Chemical Society, which Hall had received in 1912.

For more information:

Charles R. Simcoe can be reached at

crsimcoe1@gmail.com.

For more metallurgical history, visit

metals-history.blogspot.com.

Francis C. Frary,

Alcoa’s first director

of research. His

team developed

numerous alloys

that became basic

structures for

aircraft and

industrial uses.

Courtesy of

electrochem.org.

WearEver aluminum cooking utensils were the Pittsburgh

Reduction Company’s first consumer products. Courtesy

of

wearever.com.

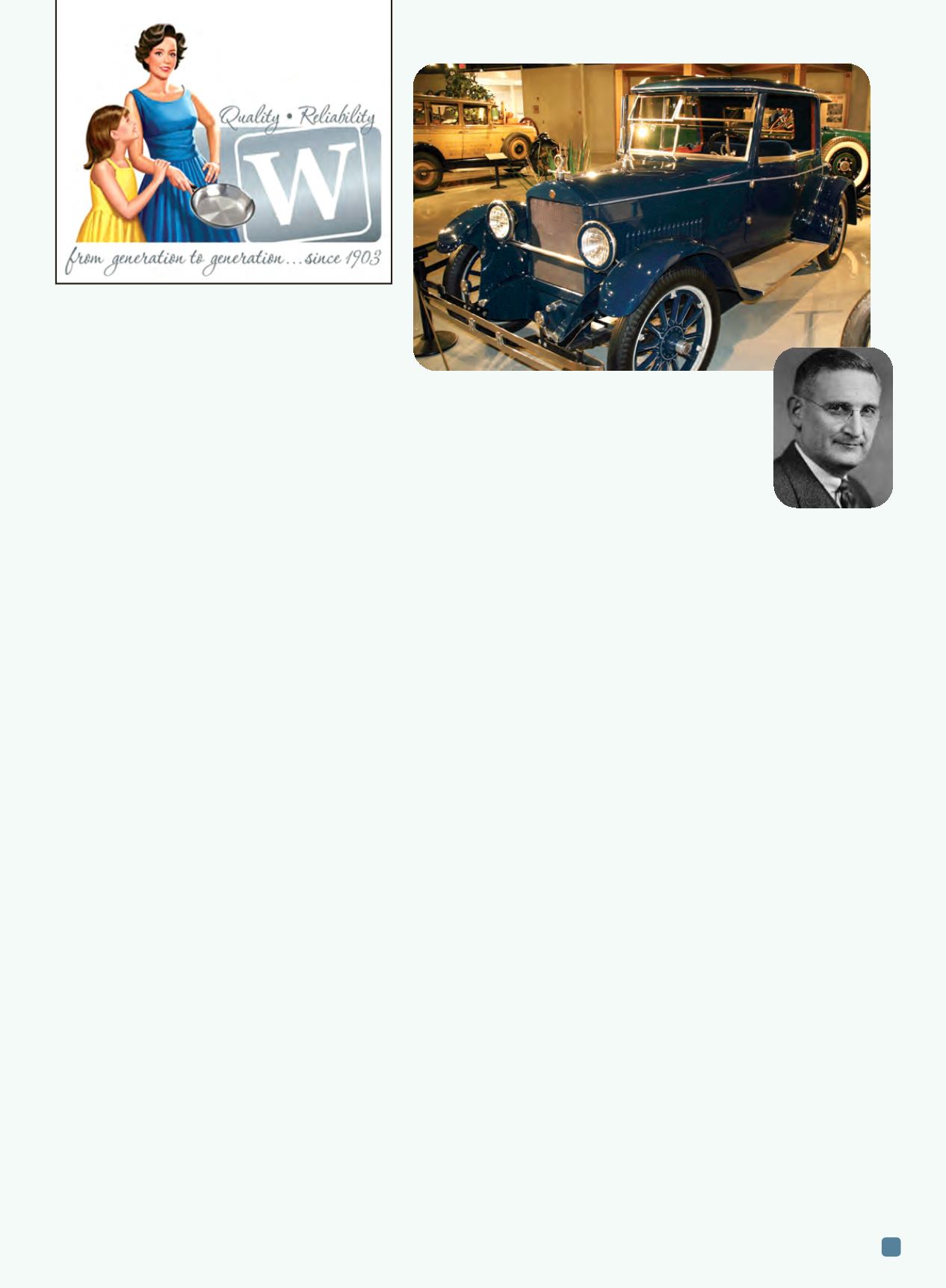

The 1924 Studebaker Light Six, part of the Studebaker

National Museum collection in South Bend, Ind., features

an all-aluminum body. Public domain image.