of PZT coatings were evaluated by various

techniques, while the phases and microstruc-

tures of coatings were investigated by XRD,

SEM, and TEM, respectively. Results show

that coatings deposited on steel substrates have

a dense microstructure, and there was no phase

transformation during spraying. Additionally, the Curie tempera-

ture of PZT coatings was roughly 370°C by the investigation of di-

electric constant.

Milestones in Functional Titanium Dioxide

Thermal Spray Coatings: A Review

M. Gardon and J.M. Guilemany

The relationship between titanium dioxide and TS technolo-

gies is explored with a goal to provide detailed information related

to the most significant achievements, lack of knowhow, and per-

formance of thermal spray TiO

2

functional coatings in photocat-

alytic, biomedical, and other applications. The influence of

thermally activated techniques such as atmospheric plasma spray

and high-velocity oxygen fuel spray on TiO

2

feedstock based on

powders and suspensions is revised; the influence of spraying pa-

rameters on the microstructural and compositional changes and

the final active behavior of the coating were analyzed. Recent find-

ings on titanium dioxide coatings de-

posited by cold gas spray and the

capacity of this technology to prevent

loss of the nanostructured anatase

metastable phase are also reviewed.

Schematic of an APS gun, interaction

between TiO

2

particles and the plasma

jet, and a representative obtained coating.

Impact Behavior of Intrinsically Brittle

Nanoparticles: A Molecular Dynamics

Perspective

B. Daneshian and H. Assadi

Impact behavior

of intrinsically brit-

tle materials at the

nanoscale is a topic

of growing interest

in aerosol deposition

and cold spraying of

ceramic materials,

for instance. The be-

havior of single-

crystalline brittle

nanoparticles upon

impact on a rigid

substrate, within the

framework of a mo-

lecular

dynamics

model was exam-

ined. The model is

based

on

the

Lennard-Jones for-

mulation, where brittleness is brought about by using a relatively

small cut-off interaction distance. Simulations were carried out for

different values of particle size and velocity. Results show that de-

spite induced brittleness, particles start to deform without break-

ing into fragments, as particle size falls below a critical value.

Deformation of particles can be accompanied by poly-crystalliza-

tion and bonding to the substrate. Results are summarized into a

parameter selection map, providing an overview of the conditions

for successful deposition of intrinsically brittle materials.

CMAS-Resistant Plasma Sprayed Thermal

Barrier Coatings Based on Y

2

O

3

-Stabilized

ZrO

2

with Al

3

+ and Ti4+ Solute Additions

Bilge S. Senturk, Hector F. Garces,

Angel L. Ortiz, Gopal Dwivedi, Sanjay Sampath,

and Nitin P. Padture

Higher operating temperatures in gas-turbine engines made pos-

sible by thermal barrier coatings (TBCs) have a new problem: Environ-

mentally ingested airborne silicate particles (sand, ash) melt on hot

TBC surfaces, forming calcium-magnesium-alumino-silicate (CMAS)

glass deposits. Molten CMAS glass degrades TBCs, leading to pre-

mature failure. Use of a commercially manufactured feedstock pow-

der, in conjunction with the air plasma spray process, deposits

CMAS-resistant yttria-stabilized zirconia-basedTBCs containingAl

3

+

and Ti

4

+ in solid solution. Results from the characterization of these

new TBCs and CMAS/TBCs interaction experiments are presented.

The ubiquity of airborne sand/ash particles and demand for higher op-

erating temperatures in future high efficiency gas-turbine engines ne-

cessitates CMAS resistance in all hot-section components. The

versatility, ease of processing, and low

cost offered by the process could bene-

fit the development of these new

CMAS-resistant TBCs.

(

a) Cross-sectional SEM image of

APS 7YSZ TBC heat treated with

CMAS (1200°C, 24 h, in air) and

(b) corresponding EDS Ca elemental

map. Horizontal dashed lines indicate

position of the TBC top surface

before CMAS interaction.

ADVANCED MATERIALS & PROCESSES •

MAY 2014

54

i

T

S

S

e

10

JTST HIGHL IGHTS

SEM micrograph of PZT

powder prepared by

solid-state reaction.

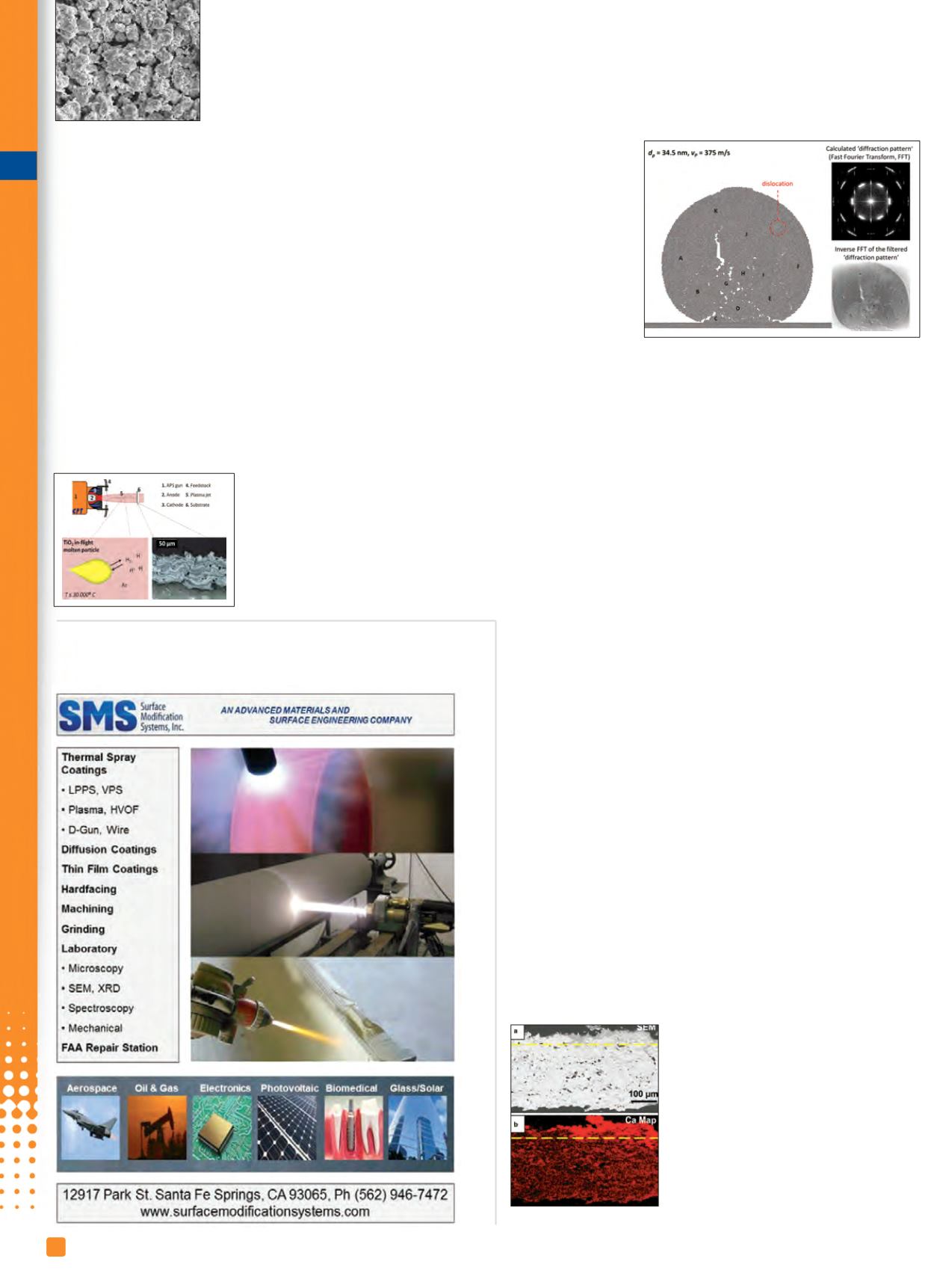

Snapshot of the atomic positions and its

respective Fourier transform (calculated

diffraction pattern) for a 34.5-nm brittle

particle impacting a rigid substrate at a

velocity of 375 m/s. Formation of

sub-grains, labeled by letters, and

dislocations are evident. Grain structure is

clearer in the inset showing the inverse

Fourier transform of the filtered diffraction

pattern.