ADVANCED MATERIALS & PROCESSES •

MAY 2014

51

i

T

S

S

e

7

and involves systematic removal of material from bulk

shapes by cutting or drilling to arrive at a final shape. Ad-

ditive manufacturing, on the other hand, builds shapes by

precisely adding and consolidating layers of materials fol-

lowing a 3D digital model

[1]

. Depending on the nature of

the materials involved (e.g., polymers vs. metals) as well as

the application, a wide range of consolidation techniques

may be used including photopolymerization, material jet-

ting, binder jetting, extrusion, powder bed fusion (laser

processing

[3-5]

), direct energy deposition (welding

[2]

and

laser processing

[3-5]

).

Currently, additive manufacturing is mostly used to

create functional prototypes or components made of

polymeric materials because consolidation techniques

for polymers are economical and readily available. At the

other end of the spectrum, additive manufacturing of

functional metallic parts has been limited by the metal-

lurgical challenges associated with consolidating metals

and other elevated temperature engineering materials of

interest. Today, selected metals, such as titanium, cobalt,

chromium, and nickel-base alloys, can be used to create

high-value custom engineered components for aviation

[6]

and medical uses.

The geometrical quality of a complex 3D shape is

dictated by spot size resolution (the smaller the better),

which is why laser beams on powder beads are the pre-

ferred method for producing intricate geometries made

of special alloys. Currently, the smallest spot size for

cold spray deposition is about 4.0 mm, which is suffi-

cient for 3D dimensional restoration of an assortment of

metallic components in the world of remanufacturing or

rapid prototyping (Fig. 3). However, a much smaller

cold spray footprint would be required to produce a

highly finished shape. Manufacturers are already work-

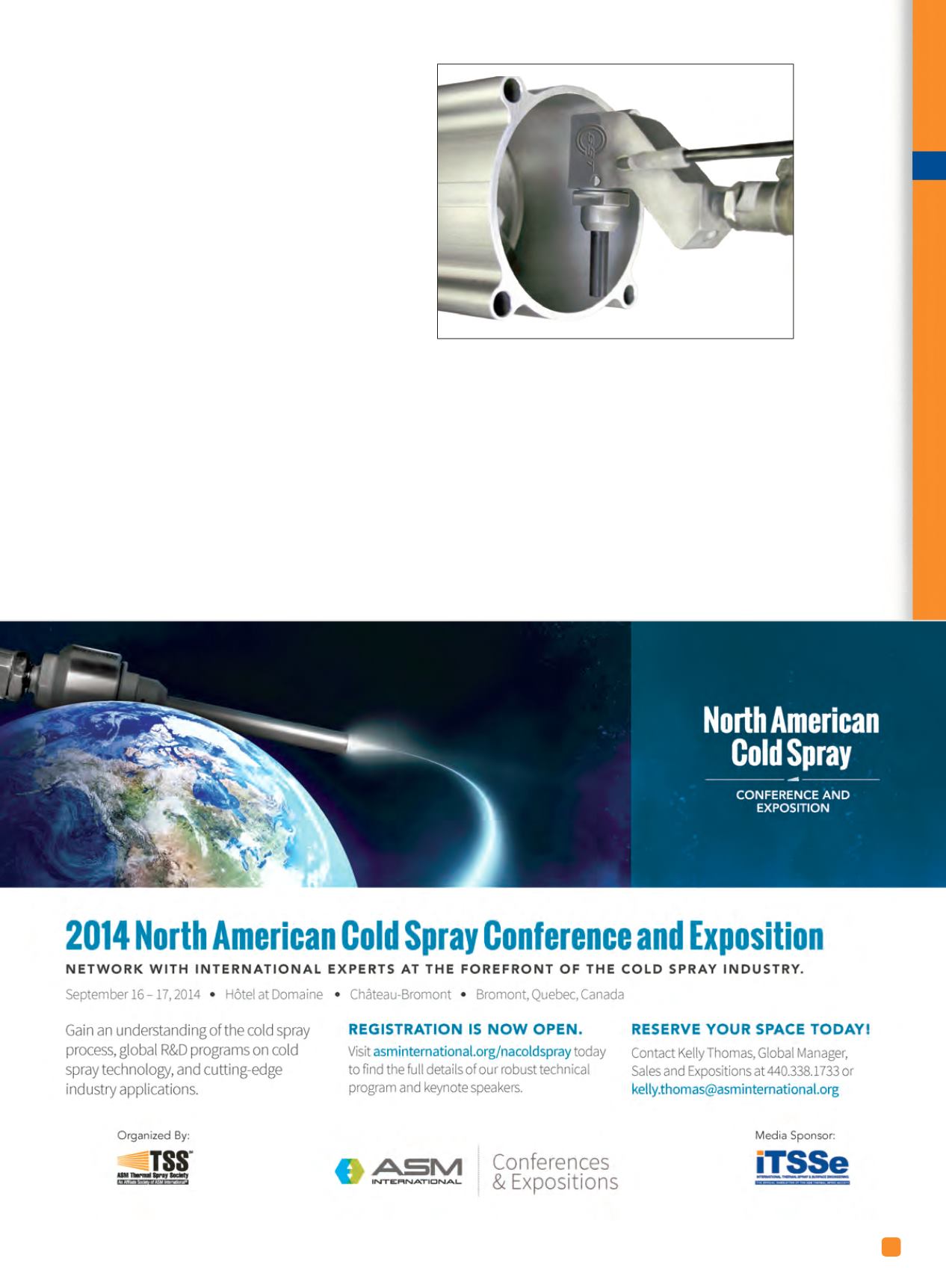

Fig. 2 —

Special right-angle nozzle assembly developed to

access hard-to-reach surfaces.