ADVANCED MATERIALS & PROCESSES •

MAY 2014

50

i

T

S

S

e

6

Considering Cold Spray

for Additive Manufacturing

T

hermal spray encompasses a variety of coating

processes that apply metals, polymers, ceramics, cer-

mets, and other materials onto metallic, polymeric, com-

posite, and ceramic substrates. One of these processes is

cold spray, which propels feedstock material against a sub-

strate with enough kinetic energy to produce a dense coat-

ing or freeform at relatively low temperatures.

Cold spray is beneficial in applications that use heat-

sensitive substrate materials or those with difficult-to-reach

spray areas. One example involves spraying inside small-

diameter, heat-sensitive tubes or bores to provide corrosion

resistance. Cold spray produces deposits that are oxide-free

and fully dense with acceptable mechanical properties. The

process requires heating of a pressurized carrier gas (typi-

cally nitrogen or air) that is passed through a “DeLaval”

convergent-divergent nozzle. The divergent section of the

nozzle creates a supersonic gas jet as the carrier gas ex-

pands toward the nozzle exit. The spray material (in pow-

der form) is injected into the gas jet either upstream or

downstream of the nozzle throat.

Depending on the process temperature, each material

requires a specific minimum particle velocity in order to

successfully form a well bonded and dense deposit. The

latter depends on the material’s ability to plastically de-

form upon impact. Therefore, the less ductile the spray ma-

terial, the more particle velocity required to produce

bonding. In practice, a cold-spray-grade powder mix must

contain, at least, one material that can easily deform upon

impact with the substrate surface.

Commercial cold spray systems, including upstream

and downstream injection systems, have been available for

more than a decade. Cold spray was primarily designed for

use in applications that are extremely sensitive to high

process temperatures. Examples include:

• Dimensional restoration of bearing surfaces of cast

aluminum and cast iron for automotive, marine,

locomotive, and earthmoving equipment

• Manufacturing of electrically conductive buses on the

delicate surface of coated conductive glass for heated

glass applications

• Deposition of pure aluminum inside semiconductor

processing chambers to reduce contamination

• Repair of corroded surfaces in magnesium

components for commercial and military aircraft

• Restoration of corrosion damage in nuclear reactor

vessels

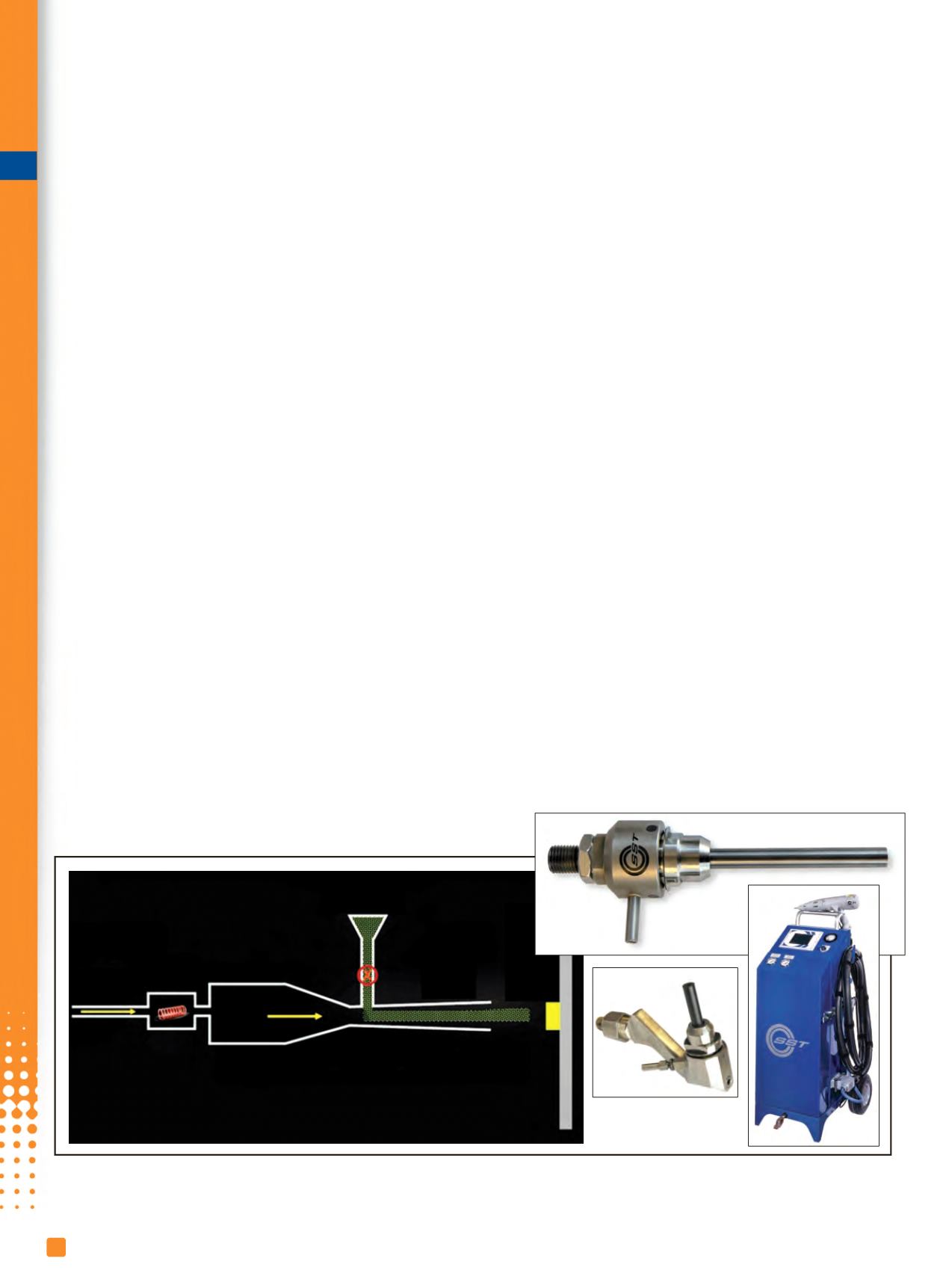

In downstream injection cold spray, the spray powder

is injected into the nozzle tube downstream of the throat.

The major benefits of this approach include the ability to

design and build smaller guns for greater accessibility and

maneuverability and the ability to manufacture practical,

low cost, durable engineered consumables that experience

minimal erosion from the spray materials (Fig. 1).

In order to spray inside hard-to-access constrained

spaces, some manufacturers developed special nozzle as-

semblies as seen in Fig. 2. Given the required short stand-

off distance (8-15 mm) and the low temperature of the

process, cold spray is considered superior to other thermal

processes with regard to surgically depositing material onto

hard-to-reach heat-sensitive surfaces, and without the need

for masking.

As manufacturing processes move forward, cold spray

is becoming more attractive as an enabling technology for

3D printing or additive manufacturing. Traditional manu-

facturing relies on subtractive manufacturing techniques,

Julio Villafuerte*

CenterLine (Windsor) Ltd.

Windsor, Ontario

*Member of ASM International and ASM Thermal Spray Society

Fig. 1 —

Downstream injection system SST Series P with manual gun, showing modular easy-access nozzles. All images courtesy of CenterLine

(Windsor) Ltd.

Powder

feeder

Gas supply

Gas heater

Carrier gas

DeLaval

nozzle

Substrate

High-velocity powder

Coating