4

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 6

ASM International

9639 Kinsman Road, Materials Park, OH 44073

Tel: 440.338.5151 • Fax: 440.338.4634

Frances Richards,

Editor-in-Chief

frances.richards@asminternational.orgJulie Lucko,

Editor

julie.lucko@asminternational.orgEd Kubel and Erika Steinberg,

Contributing Editors

Jim Pallotta,

Creative Director

jim.pallotta@asminternational.orgKate Fornadel,

Layout and Design

Annie Beck,

Production Manager

annie.beck@asminternational.orgPress Release Editor

magazines@asminternational.orgEDITORIAL COMMITTEE

Jaimie Tiley,

Chair,

U.S. Air Force Research Lab

Somuri Prasad,

Vice Chair,

Sandia National Lab

Yu-Ping Yang,

Past Chair,

EWI

Ellen Cerreta,

Board Liaison,

Los Alamos

National Lab

Steven Claves,

Alcoa Technical Center

Mario Epler,

Carpenter Technology Corp.

Adam Farrow,

Los Alamos National Lab

Nia Harrison,

Ford Motor Co.

Yaakov Idell,

NIST

John Shingledecker,

EPRI

Kumar Sridharan,

University of Wisconsin

ASMBOARDOF TRUSTEES

Jon D. Tirpak,

President

William E. Frazier,

Vice President

Sunniva R. Collins,

Immediate Past President

Craig D. Clauser,

Treasurer

Ellen K. Cerreta

Kathryn Dannemann

Ryan M. Deacon

Jacqueline M. Earle

John R. Keough

Zi-Kui Liu

Sudipta Seal

Tirumalai S. Sudarshan

David B. Williams

Tom Dudley,

Interim Managing Director

STUDENT BOARDMEMBERS

Aaron Birt, Joseph DeGenova, Sarah Straub

Individual readers of Advanced Materials & Processes may,

without charge, make single copies of pages therefrom for per-

sonal or archival use, or may freely make such copies in such

numbers as are deemed useful for educational or research

purposes and are not for sale or resale. Permission is granted

to cite or quote fromarticles herein, provided customary

acknowledgment of the authors and source is made.

The acceptance and publication of manuscripts in Advanced

Materials & Processes does not imply that the reviewers,

editors, or publisher accept, approve, or endorse the data,

opinions, and conclusions of the authors.

I

recently returned from a whirlwind visit of Germany,

as a guest of Germany Trade and Invest, the country’s

economic development agency. The organization pro-

motes Germany as a business and technology location

and supports companies with global market information.

During the tour, we visited several companies, universi-

ties, research institutions, and finally, Hannover Messe, the

world’s largest industrial trade fair. For the first time in the

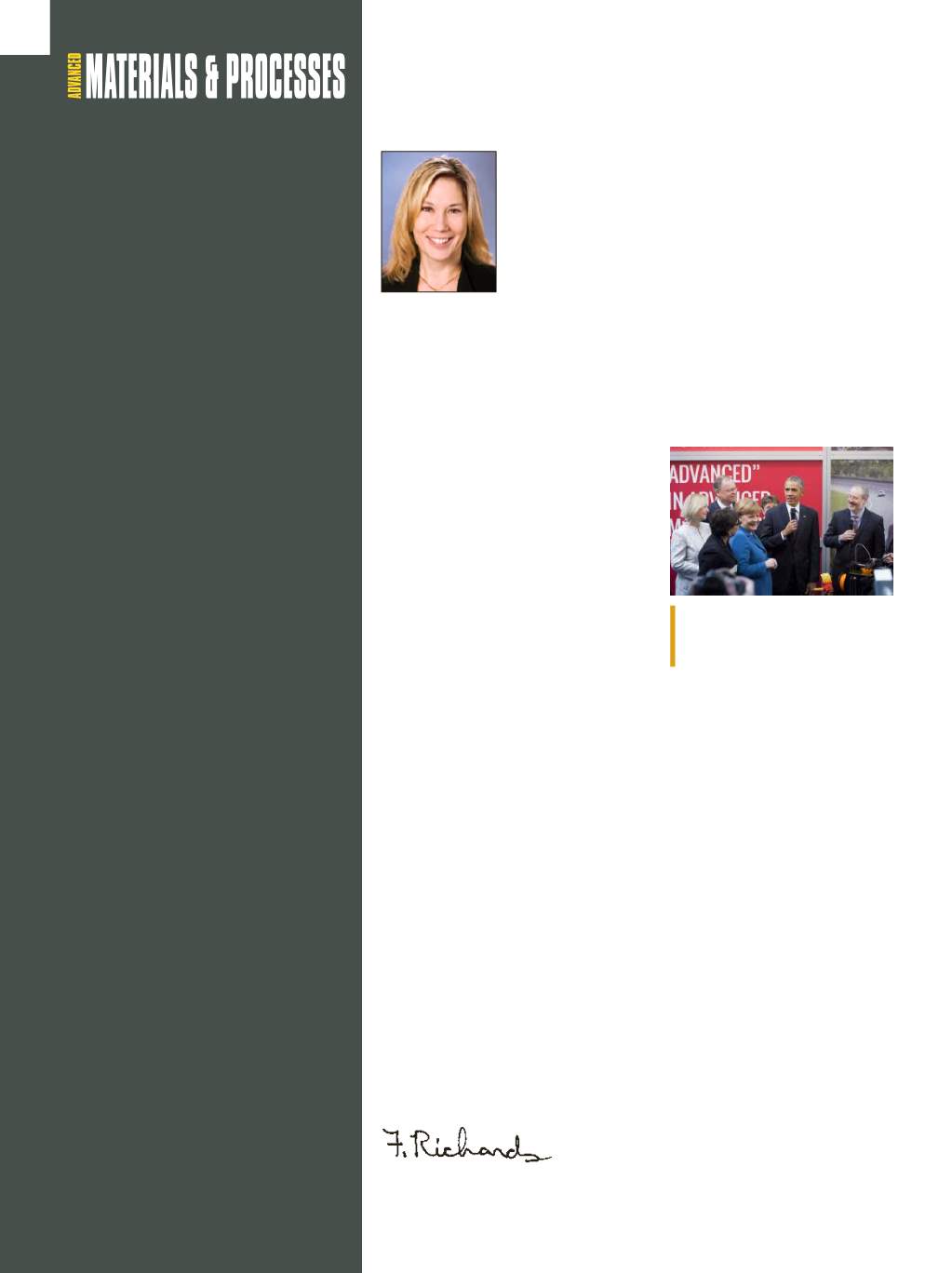

fair’s history, the U.S. was the partner country. As part of the festivities, President

Obama and German Chancellor Merkel did a special “walkaround” during the

opening morning of the exhibit. Obama’s participation at this event was the first

for a sitting U.S. President.

Hannover Messe is actually five shows in one, with separate pavilions for

industrial automation, industrial supply, digital factory, energy, and research

and technology. The overall theme was

Industry 4.0, which the U.S. often calls the

Internet of Things (IoT) or the Industrial In-

ternet. In any case, Germany is on it: The

country is investing heavily in making sure

all of its companies, universities, and re-

search organizations are on the same page

regarding what is widely being called the

fourth Industrial Revolution. As Kuka Ro-

botics’ chief technology officer said during

a panel discussion, “Data is the new oil.”

New algorithms for collecting and making

sense of data—aka

big data

—is the starting point. The premise is that by ana-

lyzing huge volumes of data, more intelligent manufacturing can be achieved,

among other goals.

Another key idea is decentralized control, where every part of a production

system has its own intelligence. From this type of setup, companies will be able

to nimbly move from mass production to mass customization. During our tour,

we visited a few companies doing just that. Kärcher, a manufacturer of cleaning

equipment, makes hundreds of slightly different versions of its machines with

very little changeover involved, simply by managing all of its production assets

digitally as orders arrive. Another company called Sensitec, located on a former

5000-employee IBM campus near Frankfurt, is fabricating its own wafers and

building customized sensors with just 170 employees. Some of these sensors

live on NASA’s Mars rovers including Curiosity, Spirit, and Opportunity. They are

also used on wind turbines, electric vehicles, train wheels, and robot joints. More

than 90% of these sensors are custom built, just the kind of tool able to collect

the data required by Industry 4.0.

Overall, the tour made me wonder what the materials community is doing

with regard to IoT initiatives. If a lesson can be learned from the Germans, it is

one of having a united and organized approach to moving its industry forward

into the digital future. If you have an opinion on how these ideas will impact ma-

terials science and engineering, we’d like to hear it.

frances.richards@asminternational.orgTHE INTERNET OF THINGS—

YES, ‘IT’S A THING’

German Chancellor Merkel and

President Obama visit with

MakerGear at Hannover Messe.