FEATURE

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A R C H 2 0 1 6

4 4

10

three vacuum heat treating processes per various aerospace

standards—vacuum annealing, vacuum aging, and vacuum

stress relieving.

Typically, prior to heat treating, EBAM baseplates are

severely warped due to high heat concentration of the elec-

tron beam on one side of the base material. To counteract

the warping, AM companies are trying to simultaneously

print on both sides of the base plate. Until the distortion can

be better controlled, vacuum annealing and vacuum stress

relieving processes are used to “creep form” the parts back

into shape so they can be finish machined. Graphite plates,

molds, and stainless steel weights are used to help accom-

plish this task (Fig. 7).

Because BJP involves very little heat during manufac-

turing, downstream heat treating is often challenging. As

with metal injection molding (MIM) metallurgy, the BJP part

must be fully densified by vacuum sintering. Sintering tem-

peratures are often within 10°F of the melting point of the

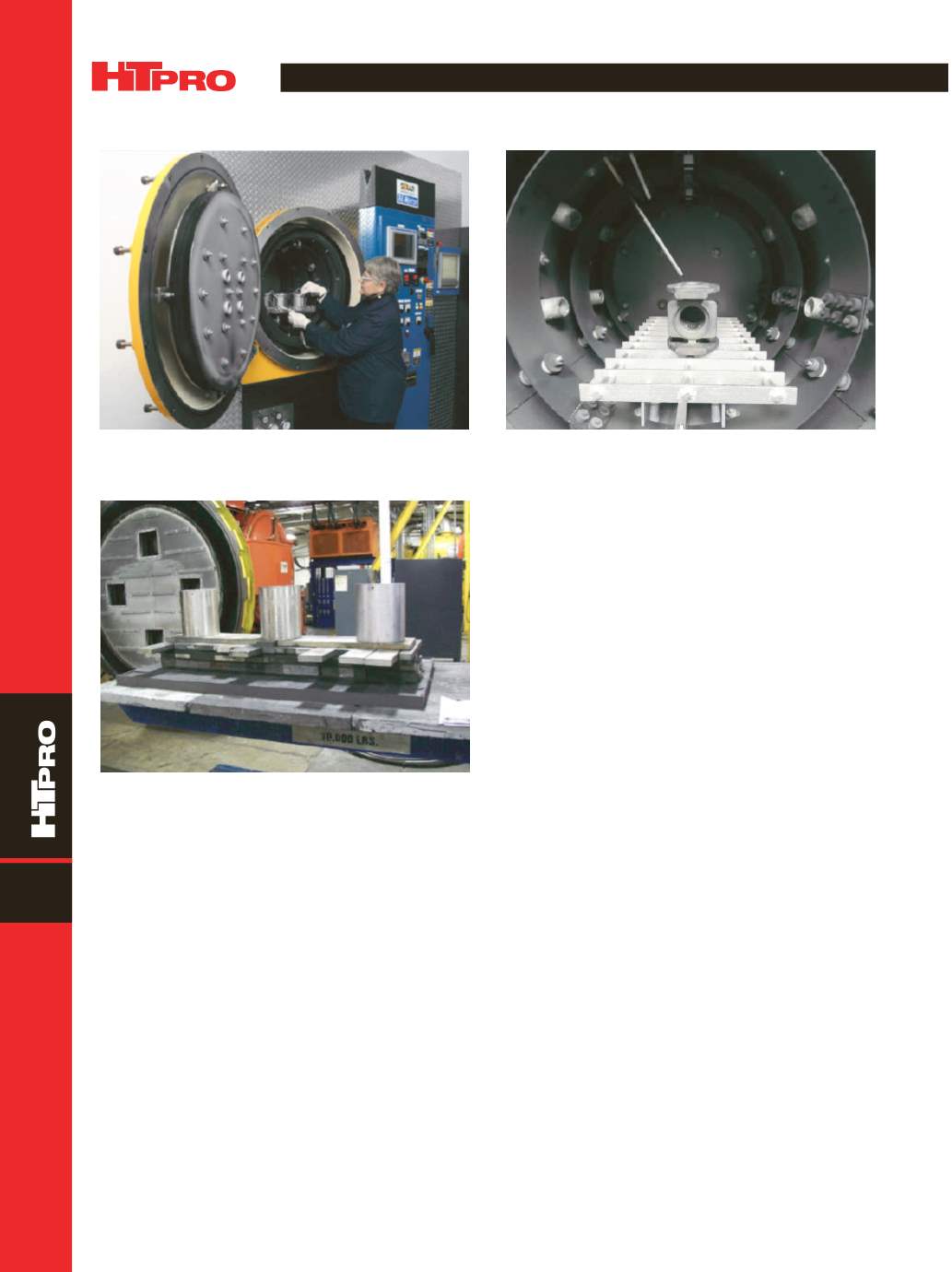

Fig. 5 —

AM-capable vacuum furnaces range from lab size to

48 ft long.

Fig. 6 —

Heat treating a BJP-printed part requires precise tem-

perature measurement.

base material, so precise pyrometric control is critical. In

addition, slow ramp-up rates and various holding times are

crucial to bake off residual binders remaining within the de-

lubed parts.

CONCLUSIONS

Global 3D printing industry revenues from products

and services exceeded $2.2 billion in 2014. Revenues for the

global market are expected to exceed $21 billion by the year

2020, according to the

Wohlers Report on Additive Manufac-

turing and 3D Printing.

The aerospace industry is not the only niche market

where AM is making its mark. AM in the medical device mar-

ket has also grown significantly. The technology’s geometric

design freedomisparticularlyuseful inorthopedics, enabling

the design of more natural anatomical shapes while printing

the porous surfaces required for bone grafting purposes.

Additive manufacturing is not yet the manufacturing

panacea portrayed by its enthusiasts. Today, 3D printing is

not likely to replace traditional machining, because AM only

eliminates some—and not all—machining. Even the best

finish produced by printing requires final machining and/

or grinding, especially for parts that need to be assembled

to other components. Additive manufacturing is not about

forcing manufacturers and heat treaters to abandon conven-

tional manufacturing processes used for decades. However,

it offers an exciting alternative manufacturing method, espe-

cially when savings can be realized in design flexibility and

fewer manufacturing steps—or even billions of dollars in jet

fuel.

For more information:

Robert Hill is President, Solar At-

mospheres of Western PA, 30 Industrial Rd., Hermitage, PA

16148, 724.982.0660, ext. 2224,

bobh@solarwpa.com,

www. solaratm.com.

Fig. 7 —

Creep-forming is used to flatten a warped EBAM titanium

baseplate by placing weights on the part during heat treatment.