Betterbamboobuildings

Scientists at Massachusetts Insti-

tute of Technology, Cambridge, along

with architects and wood processors

from England and Canada, are looking

for ways to turn bamboo (shown above)

into a construction material more sim-

ilar to wood composites, like plywood.

The idea is that a stalk, or culm, can be

sliced into smaller pieces, which can

then be bonded together to form sturdy

blocks—much like conventional wood

composites. A structural product of this

sort could be used to construct more re-

silient buildings—particularly in places

like China, India, and Brazil, where bam-

boo is abundant. The goal is to gain a

better understanding of these materials,

so bamboo can be used more effectively.

Researchers have analyzed the micro-

structure of bamboo and found that it is

stronger and denser than North Ameri-

can softwoods like pine, fir, and spruce,

making it a promising resource for com-

posite materials. Photo courtesy of Jen-

nifer Chu/MIT.

web.mit.edu.

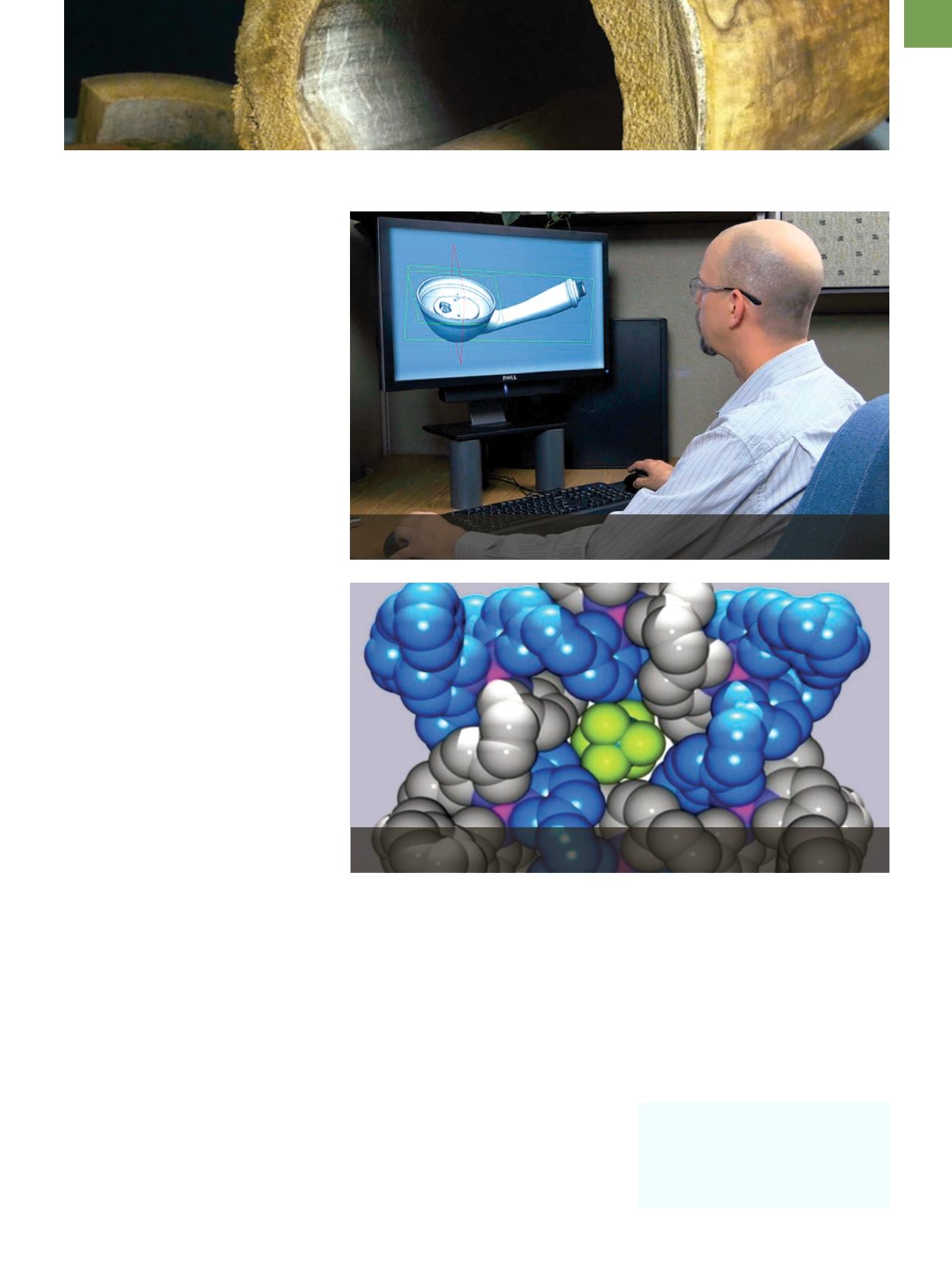

3D printing isoldhat

inshowerheads

Water Pik Inc., Fort Collins, Colo.,

has been using 3D printer technology

for nearly 20 years to speed design pro-

cesses and create high-performance

products. 3D printing allows designs to

be fine-tuned and is up to 10 times faster

than traditional prototyping. This gives

engineers time to refine designs to meet

rigorous performance requirements and

address consumer needs. The company

recently released a video highlighting the

prototyping process, which provides an

inside look at the 3D printer technology

in place. The video also demonstrates

how shower heads are tested to meet

rigorous OptiFLOW (the power behind

Waterpik shower heads) technology

performance standards.

waterpik.com/ shower-head/blog/3d-printer-video.Starof Davidshines as

moleculardiscovery

Consisting of two molecular trian-

gles, entwined about each other three

times into a hexagram, the Star of David’s

interlocked molecules are tiny—each tri-

angle is 114 atoms in length around the

perimeter. The molecular triangles are

threaded around each other at the same

time that the triangles are formed, by a

process called self-assembly—similar to

how the DNA double helix is formed in bi-

ology. The molecule was created at The

University of Manchester, UK, by Alex Ste-

phens. Professor David Leigh says, “It’s

the next step on the road to man-made

molecular chainmail, which could lead to

the development of new materials that

are light, flexible, and very strong. Just

as chainmail was a breakthrough over

heavy suits of armor in medieval times,

this could be a big step towards mate-

rials created using nanotechnology.”

www.manchester.ac.uk.

OMG!

outrageousmaterialsgoodness

A Waterpik shower head design is prepped for 3D printing.

Are you working with or have you

discovered a material or its properties

that exhibit OMG - Outrageous

Materials Goodness?

Send your submissions to Julie Lucko at

julie.lucko@asminternational.org.

Atoms in the Star of Davidmolecule. Courtesy of The University of Manchester.

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | F E B R U A R Y

2 0 1 5

7