Understanding failure

inglassymaterials

Researchers at University of Penn-

sylvania, Philadelphia, discovered an

important commonality that seems to

extend through the wide range of glassy

materials. They demonstrated that the

scaling between a glassy material’s stiff-

ness and strength remains unchanged,

implying a constant critical strain that

these materials can withstand before

catastrophic failure, despite the extreme

variation found among the physical

properties of different glasses. This con-

stant critical strain provides insight into

the fundamental “seed” out of which

glass failure grows—a small group of the

glass’s constituent particles or atoms

that change shape in a collective way.

Despite the disorder that epitomizes

glass, this coordinated activity appears

to be universal among many glassy sys-

tems, such as certain metals, polymers,

and colloids, and is an important starting

point for designing more durable materi-

als.

For more information: Daniel Gianola,

215.898.7246,

gianola@seas.upenn.edu,

www.seas.upenn.edu.

Inaugural photonic

pressure sensor

outshinesmercurymodel

A unique pressure-sensing device

recently surpassed the performance of

the best mercury-based techniques in

resolution, speed, and range at a frac-

tion of the size, according to scientists

at NIST, Gaithersburg, Md. The new in-

strument, called a fixed-length optical

cavity (FLOC), works by detecting sub-

tle changes in the wavelength of light

passing through a cavity filled with ni-

trogen gas.

The FLOC system is poised to de-

pose traditional mercury pressure sen-

sors (manometers) as the standard used

to calibrate commercial equipment,

according to researchers. The new de-

sign is also a promising candidate for a

factory-floor pressure instrument that

could be used by a range of industries, in-

cluding semiconductor, glass, and aero-

TESTING | CHARACTERIZATION

BRIEFS

Nikon Instruments Inc.,

Melville, N.Y., entered a strategic partnership with

JEOL,

Peabody, Mass., to develop techniques to address correlative light and electron

microscopy. Along with progress in super-resolution technologies, there is growing

interest in correlating light microscopy data with electronmicroscopy data to further

push the limits of resolution. The alliance plans to develop tools to combine the

advantages of both methods.

nikoninstruments.com,

jeolusa.com.

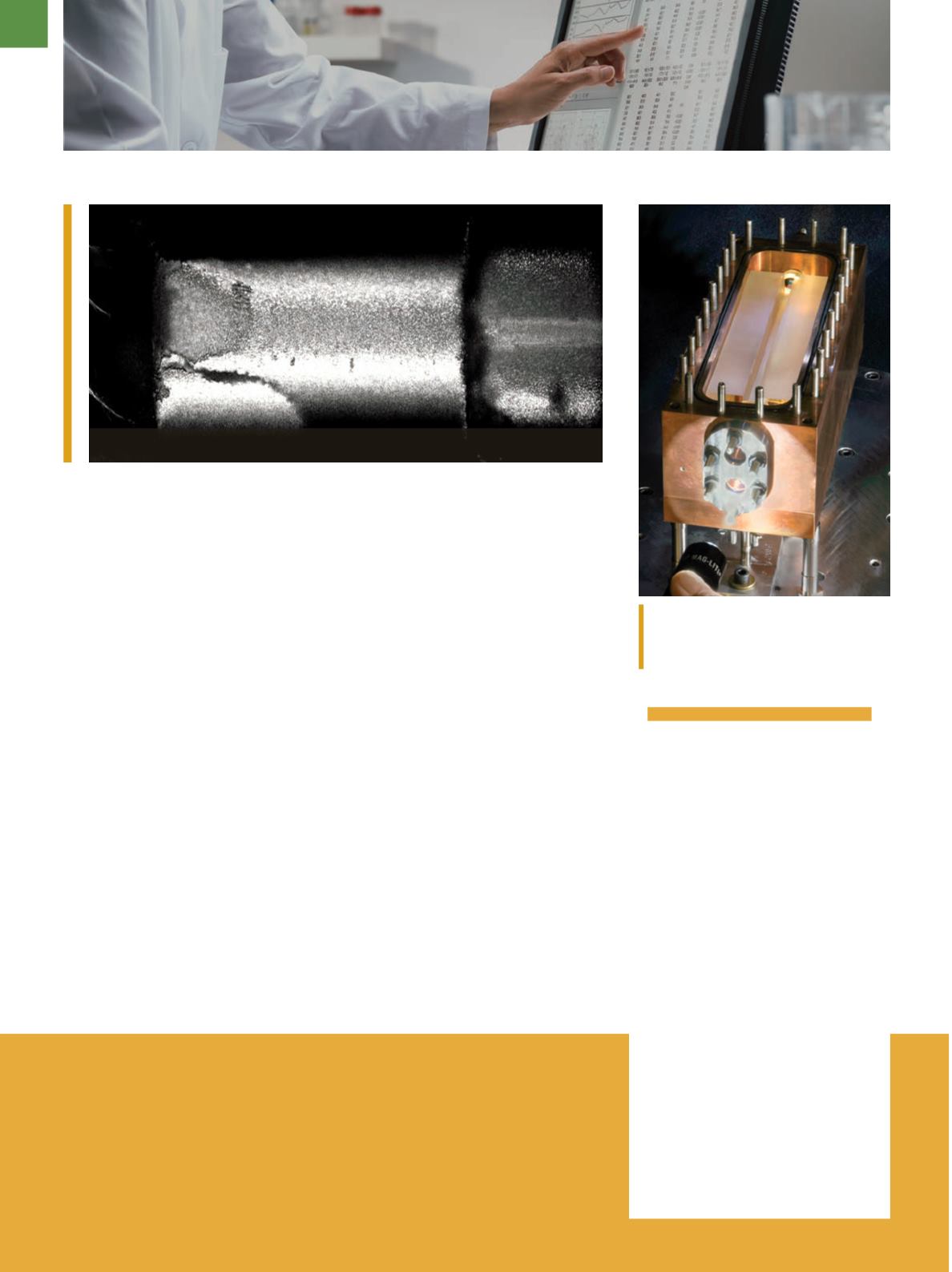

Microscope image of a micropillar failing after the formation of a shear band.

Sigma Labs Inc.,

Santa Fe, N.M., a

developer of inspection

systems for metal-based

additive manufacturing

technologies, received a

contract from Honeywell

Aerospace as part of a

Defense Advanced

Research Project Agency

(DARPA) Phase II award

to develop an integrated

computational materials

engineering (ICME)

framework to

accurately predict the

properties of metal

components produced

using additive

manufacturing.

sigmalabsinc.com.

FLOC gauges pressure by detecting

subtle differences in the wavelength

of light resonating in two channels.

Courtesy of NIST.

A D V A N C E D M A T E R I A L S & P R O C E S S E S | F E B R U A R Y 2 0 1 5

1 0