48

Vital Statistics:

In early 2012, Lockheed Martin’s Space Systems Co. began to look for ways to

improve its satellite design. The goal: Devise a satellite that more efficiently uses

the available design footprint to increase payload capacity. This effort required

testing various assembly configurations and producing several simulators and pro-

totypes to validate design changes. One of these changes involved the satellite’s

fuel tanks.

Before building the actual tanks for final use, Lockheed needed to test form,

fit, and function—and assembly—by using tank simulators. However, producing

test parts with traditional manufacturing methods was not an option given the

tight deadlines and financial constraints: Machining the larger tank at 6.75 × 3.8

× 3.8 ft and the smaller one at 3.8 × 3.8 × 3.8 ft would take longer than six months

and cost around $250,000. Recent advancements in large-scale 3D printing moti-

vated Lockheed to apply Stratasys’ fused deposition modeling (FDM) technique to the tank simulators.

Although Lockheed owns several additive manufacturing machines, this particular application involved part sizes and

project deadlines that exceeded its in-house capacity. Parts needed to be built in many pieces and bonded together, re-

quiring an army of machines and a crew of FDM finishing experts. That’s when they turned to the aerospace team at

RedEye, a division of Stratasys Inc.

Success Factors:

The larger tank was built in 10 separate pieces, and the smaller in six, using polycarbonate material. Combined, the

fuel tanks took nearly two weeks to print, requiring approximately 150 hours per section. Based on the sheer size of the

parts, customized fixtures were needed to support the structures as they were bonded together and then shipped to a ma-

chining facility to meet specifications. Once machining was complete, final

assembly took 240 hours.

“These are the largest parts we’ve ever built using FDM,” says Joel Smith,

RedEye’s aerospace and defense account manager. “We completed an exten-

sive design review to determine the best orientation and slice height to en-

sure we could accurately build and bond the sections together in post

processing to meet the dimensional requirements.”

About the Innovators:

As a division of Stratasys, RedEye is one of the world’s largest providers

of rapid prototyping and additive manufacturing services and has a network

of more than 150 3D printers worldwide. RedEye uses Stratasys’ FDM and

PolyJet 3D printing

technologies to help

companies with

all

phases of product de-

velopment, from con-

ceptual modeling to

production of end-use

parts. Lockheed Martin’s Space Systems Co. designs, develops, tests,

manufactures, and operates advanced technology systems for na-

tional security, civil, and commercial customers.

What’s Next:

The tanks went through several quality assurance and accuracy

measurements and were approved for the first concept assembly.

Next, Lockheed will take what they learned from the first phase to optimize design and assembly to print the second

iteration of tanks.

Contact Details:

Joel Smith, Strategic Account Manager for Aer

ospace and DefenseRedEye, a division of Stratasys

Inc. 8081 Wallace Rd., Eden Prairie, MN55344

866.882.6934,

godigital@redeyeondemand.com,redeyeondemand.com

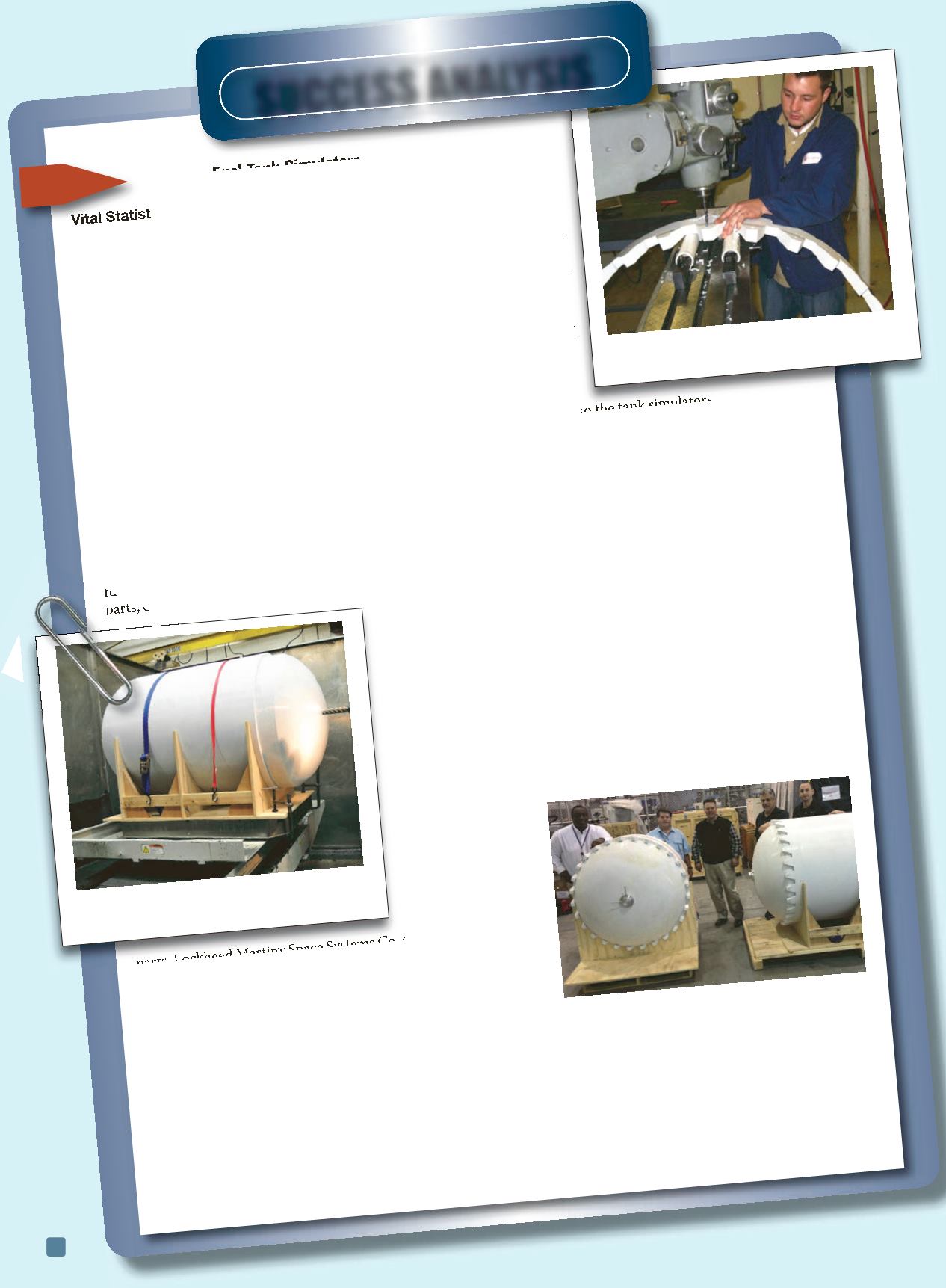

The RedEye and Lockheed Martin team with

the 3D printed tank simulations.

Adding inserts to the 3D printed tank

simulation rings.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

3D Printed Fuel Tank Simulators

Specimen

Name:

SucceSS AnAlySiS

Both 3D printing and traditional

manufacturing methods were used to machine

the 3D printed tank simulations.