Exclusive color developed for company’s 75th anniversary

Axalta Coating Systems, Glen Mills, Pa., developed a special formulation of

Diamond Red exclusively for Peterbilt, Denton, Tex. Peterbilt is celebrating its

75th anniversary this year by unveiling a limited production Model 579 truck

featuring state-of-the-art aerodynamics, distinctive styling, and coated with a

two-tone paint design that is a modern version of the Diamond Red color

on its original 1939 model. The Imron Elite paint line is the exclusive

topcoat used at Peterbilt manufacturing facilities in the U.S.,

Canada, and Mexico. An identical product is used in the

commercial vehicle aftermarket by Peterbilt dealers and repair

centers to ensure customer satisfaction and repair-in-kind quality.

axaltacoatingsystems.com,

peterbilt.com.

Peterbilt’s exclusive new color, Diamond Red, is formulated to bring

out the lines and details of the truck, while showcasing new effect

pigments in the Imron Elite paint line from Axalta Coating Systems.

ADVANCED MATERIALS & PROCESSES •

JULY 2014

47

3D printing old milk jugs

A study led by Joshua Pearce of Michigan

Technological University (MTU), Houghton, shows that

making plastic 3D printer filament from milk jugs uses less

energy—often a lot less—than recycling them

conventionally. The team did a life cycle analysis on a

typical milk jug made from high-density polyethylene

(HDPE) plastic. After cleaning it and cutting it in pieces, it

was put through an office shredder and a RecycleBot,

which turns waste plastic into 3D printer filament.

Compared to an ideal urban recycling program, which

collects and processes plastic locally, turning milk jugs

into filament at home uses about 3% less energy.

“Where it really shows substantial savings is in smaller

towns, where you have to transport the plastic to be

collected, then again to be recycled, and a third time to be

made into products,” says Pearce, associate professor of

materials science and engineering. In this scenario, energy

savings skyrocket to 70-80%. And, recycling your own

milk jugs uses 90% less energy than making virgin plastic

from petroleum.

For more information: Joshua Pearce,

906.487.1466,

pearce@mtu.edu,

mtu.edu.

Old milk jugs can be recycled into filament for 3D printing, saving both

money and the environment. Courtesy of Sarah Bird/MTU.

National Geographic Kids

claimed its ninth

Guinness World Records title for the smallest

magazine cover, using patented technology

from IBM, Armonk, N.Y.

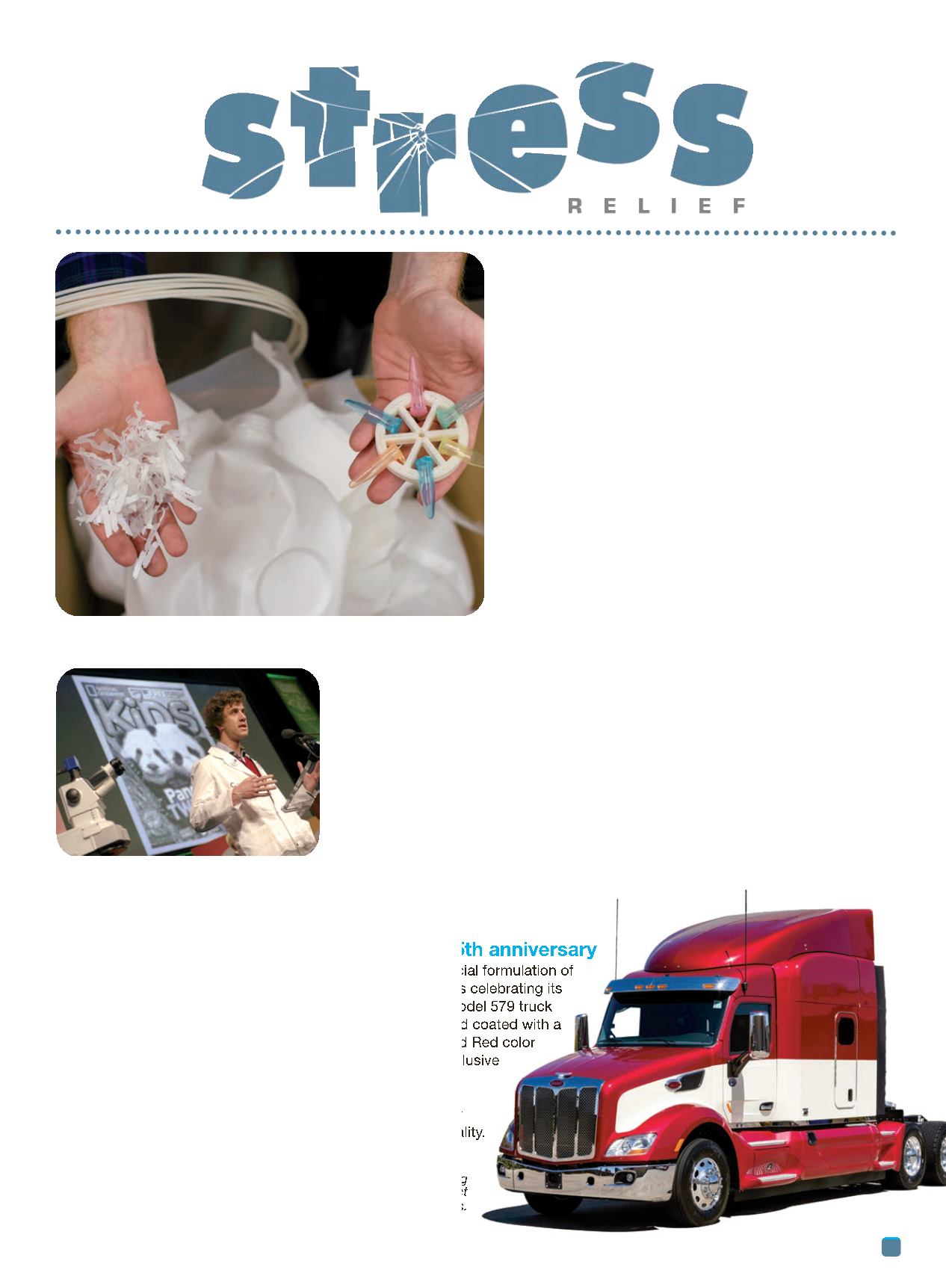

The world’s tiniest magazine cover

National Geographic Kids

claimed its ninth Guinness World Records title for the

smallest magazine cover, using patented technology from IBM, Armonk, N.Y., at the

USA Science & Engineering Festival in Washington. To create the record-setting

cover, IBM scientists invented a tiny “chisel” with a heatable silicon tip 100,000

times smaller than a sharpened pencil point. Using this nanosized tip, which

creates patterns and structures on a microscopic scale, it took scientists just 10

minutes and 40 seconds to etch the magazine cover onto a polymer. The resulting

magazine cover measures 11 × 14 µm.

National Geographic Kids

let its readers vote online for their favorite design and

they chose the March 2014 cover, which earned the honor of a microscopic

version, visible through a ZEISS Axio Imager 2 microscope

.

research.ibm.com,

guinnessworldrecords.com,

kids.nationalgeographic.com.