ADVANCED MATERIALS & PROCESSES •

JULY 2014

44

l i terature

products &

Dow Corning Corp., Midland, Mich., introduced two new

Silastic brand

fluoro liquid silicone rubbers

(F-LSRs)

to expand design options and provide processing effi-

ciency for fuel-resistant automotive components. Meet-

ing key market needs for both performance and cost

control, Silastic F-LSRs combine the fuel, oil, and sol-

vent resistance of fluorosili-

cone rubber (FSR) with the

processing benefits of liquid

silicone rubber (LSR). Both

Silastic F-LSRs exhibit excel-

lent resistance to nonpolar

hydrocarbon fuels, oils, and

solvents and offer process cost savings as well. Silastic

FL-60-9201 F-LSR provides flexibility for dynamic seals

such as diaphragms and membranes, while Silastic

FL-70-9201 F-LSR provides high modulus with low com-

pression set for static seals such as O-rings and gas-

kets.

dowcorning.com.

FLIR Systems, Wilsonville, Ore., introduced the FLIR

A6700sc—an economical

compact thermal imaging

camera,

which incorporates a cooled Indium Anti-

monide (InSb) detector that

operates in the 3-5 µm

waveband. A broadband

version operating on the

1-5 µm waveband is also

available. Both versions

produce crisp thermal images

of 640 × 512. Achieving a high thermal sensitivity of

<20 mK, the camera captures the finest image details

and temperature difference information. Precise camera

synchronization and triggering make it well suited to high

speed, high sensitivity applications. The camera sup-

ports image frame rates up to 480 frames per second

when operating in windowing mode.

flir.com/US.Green Belting Industries Ltd.,

Mississauga, Ontario, re-

leased a unique problem solv-

ing product—HVMT Orange

masking tape

that can sur-

vive the abrasion and heat as-

sociated with gas fueled

HVOF (high velocity oxy fuel)

coatings. It delivers clean

coating lines and no adhesive

residue. The tape is flame retardant, self-extinguishing,

highly abrasive resistant, and very flexible and conform-

able.

greenbelting.com.

Unitel Technologies Inc., Mt. Prospect, Ill., joined with

Inorganic Polymer Solutions Inc., Blacksburg, Va., to

commercialize a 100% VOC-free

inorganic coating.

Its

performance is not affected by high temperatures, oxy-

gen-deficient conditions, or marine environments. Ce-

ramiGuard provides a new option to fight corrosion with

two steps in one: An acid phosphate gel provides the

passivation layer while an alkaline colloidal gel forms the

protective refractory ceramic top-coat. Underlying

chemical reactions occur simultaneously. The unique ad-

vantage of this new coating is that the ceramic is formed

by an in situ chemical reaction and not by conventional

high temperature processing of inorganic powders.

uniteltech.com,

polymersolutions.com.

Thermo Scientific, Waltham,

Mass., introduced the UltraDry

Compact EDS

x-ray detector.

Small enough to fit in the palm

of the hand, it features a main-

tenance-free design that elim-

inates the need for liquid

nitrogen. The detector handles

collection rates up to one mil-

lion x-rays per second with de-

tection sensitivity to boron and

EDS energy resolutions of 129

eV Mn. The streamlined design

makes it suitable for tabletop SEMs, as well as a tight fit

on new SEMs or as a cost-effective replacement EDS

for existing SEMs.

thermoscientific.com.

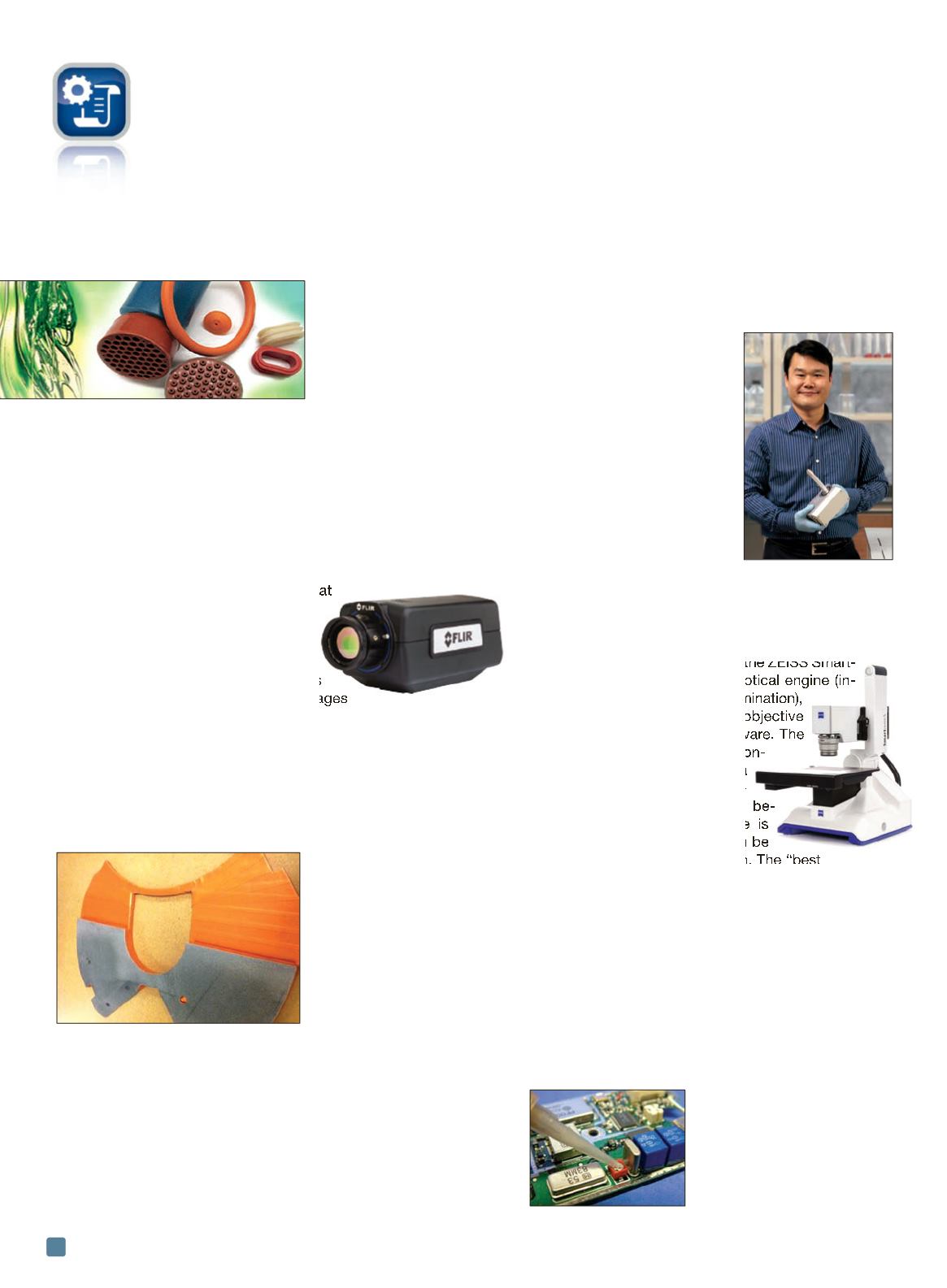

Carl Zeiss Microscopy, Peabody, Mass., released its first

automated digital microscope,

the ZEISS Smart-

zoom 5. It is comprised of an optical engine (in-

cluding a zoom, camera, and illumination),

a stand with sample stage, objective

lenses, operating unit, and software. The

microscope is well suited to con-

ducting failure analyses. Once a

sample is placed under the de-

vice, switching back and forth be-

tween the device and software is

unnecessary as all the steps can be

completed directly on the screen. The “best

image” feature allows users without any prior knowledge

to achieve optimal results—the system shows a preview

of different illumination options and the user selects the

best one. The device is factory calibrated and can be

used immediately.

zeiss.com.

Master Bond, Hackensack, N.J., introduces MasterSil

152, a two-component,

condensation curing system

that only requires air for complete cross-linking. It was

developed for potting and encapsulation applications

where additional cured silicone cannot be used. The sys-

tem fully cures at room temperature in 24-48 hours, has

low exotherm and low shrink-

age upon curing, and features

a 10:1 mix ratio by weight.

MasterSil 152 combines low

viscosity and electrical insula-

tion properties with the ability

to cure in sections exceeding