R

are earth products are essential ingredients in magnets and mag-

netic powders, catalysts, metallurgical additives, polishing powders,

phosphors, glass additives, ceramics and other engineered rare earth ma-

terials, as well as batteries, motors and generators, lasers, drives, sensors,

and other components and systems used in a variety of industries. In turn,

these products are used in health care, clean energy, automotive, light-

ing, communications, audio equipment, defense, electronics, advanced

optics, oil refining, and many other sectors.

In a first-of-its-kind analysis, the Rare Earth Technology Alliance and

the American Chemistry Council recently released a free report that takes

an in-depth look at the economic impact of rare earths.

The Economic

Benefits of the North American Rare Earths Industry

analyzes the eco-

nomic footprint of the rare earth industry in terms of its direct, indirect,

and induced effects as measured by output, payrolls, jobs, and tax rev-

enue. Some highlights include:

• The rare earth industry directly contributes to the North American

economy with $795 million in shipments, employing nearly

1050 workers with a payroll of $116 million.

• Adding other upstream impacts to its direct impact, the industry

generates a total of $1.9 billion in economic output in

North America.

The industry supports $329.6 billion in economic output in down-

stream end-market products

and technologies that employ

618,800 workers (with a com-

bined payroll of $37.6 billion)

in the U.S. and Canada.

In the report,

rare earth

is

used as a generic term for the

15 lanthanides of the periodic

table as well as scandium and

yttrium. Rare earths were dis-

covered in 1787 by Karl Axel

Arrhenius, an officer in the

Swedish army, when he gath-

ered the black mineral ytter-

bite (later renamed gadolinite)

from a feldspar and quartz

mine adjacent to the hamlet of

Ytterby, Sweden. Due to simi-

larity in the elements and the fact that they occur in nature as a group, or

subgroup, without separation by natural forces, rare earth elements are

not easily isolated. The first commercial applications for rare earths arose

during the 1880s with the introduction of the Welsbach incandescent

lamp, which initially required the oxides of zirconium, lanthanum, and

yttrium. By 1900, rare earths found other applications in lighting. Over

the past 110 years or so, the use of rare earths has grown from a few hun-

dred metric tons to more than 80,000 tons consumed annually.

For more

information, visit

rareearthtechalliance.com.

ADVANCED MATERIALS & PROCESSES •

JUNE 2014

4

spot l ight

feedback

market

Free report explores economic

impact of rare earth industry

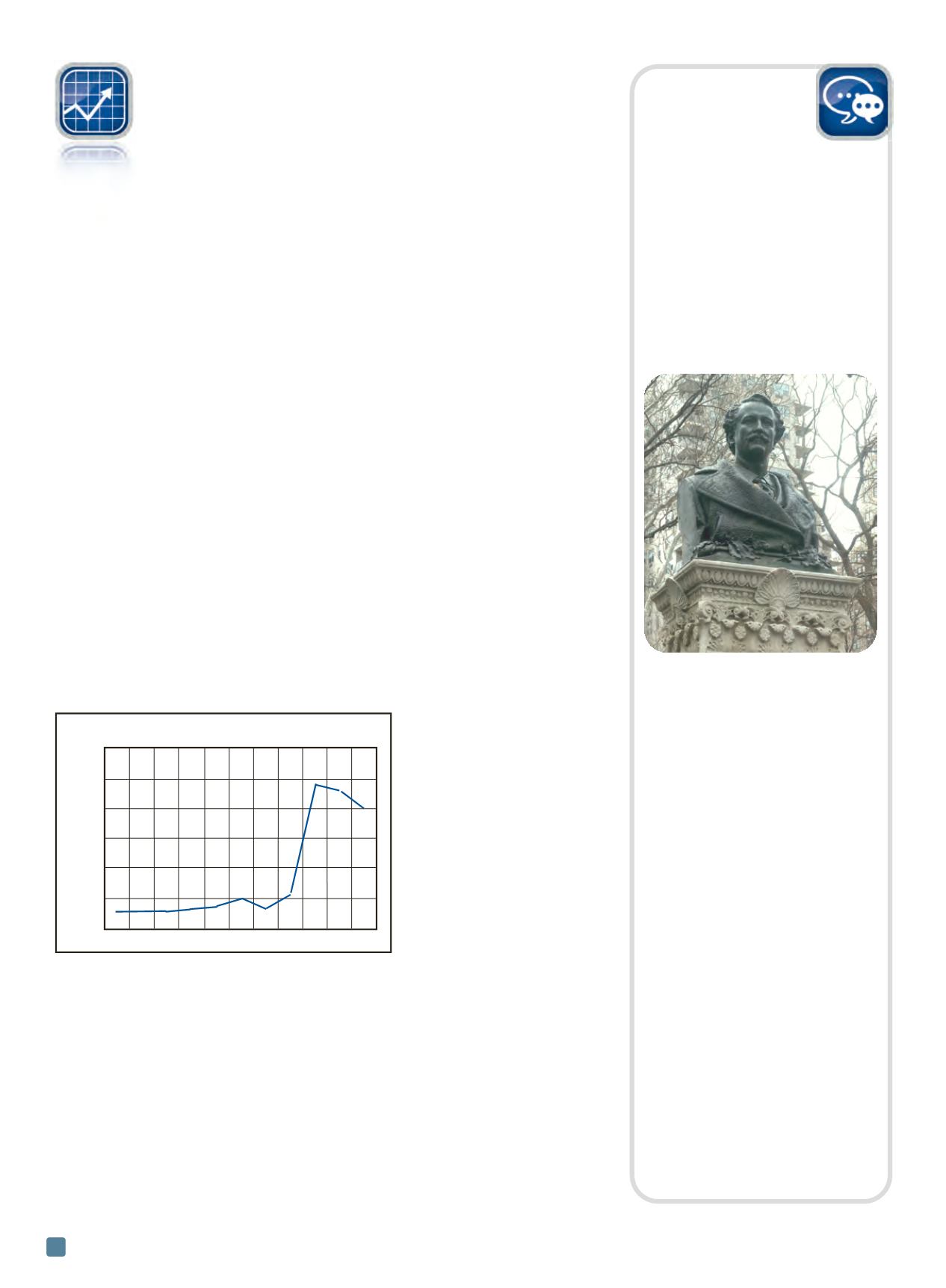

Holley needs help

I have been enjoying your articles on

“The Age of Steel.” Thank you for putting

these together. A number of years ago, I

visited the Holley monument in Washing-

ton Square Park. At the time, his name

was clearly visible but the inscription had

weathered away. I contacted ASM with

a suggestion that the Historical Commit-

tee make it a project to install a plaque

with the details of who he was. I heard

no reply, so I assume nothing was done.

Is it time to try again?

J.W. Matousek, ASM Life Member

The bust of Alexander Lyman Holley

stands in Manhattan’s Washington

Square Park, but could use an

informative plaque

.

Historical files, book available

I enjoyed the recent “Age of Steel:

Part II” article immensely (April issue).

Charles Simcoe is to be commended for

writing this article series. I have taken

an interest because I read a book on the

Homestead steel strike about 60 years

ago. I worked at U.S. Steel Homestead

Works in the metallurgy department

from 1951 to 1954. Later, I was the pri-

mary nickel specialist for an INCO nickel

distributor. During this time, I called on

U.S. Steel’s Johnstown Works where

they had the original Kelly converter in

their reception room.

After closing my company two years

ago, I’ve been disposing of my library. I

have files on the conversion of a blast

furnace from making iron to making fer-

romanganese by Pittsburgh Coke and

Chemical Co. at their plant on Neville Is-

land, Pa. I also have a small book called

Acid Electric Steelmaking

printed by

ASM in 1947. I would like these things to

go to whomever would be interested,

free of charge.

J. Gray Bossard, ASM Life Member

We welcome all comments

and suggestions. Send letters to

frances.richards@asminternational.org.

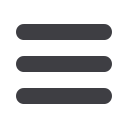

Based on data from the Census Bureau, U.S. Geological

Survey, and Statistics Canada, North American shipments

of rare earth materials were $795 million in 2013. This

includes both mining and manufacturing of basic rare

earth materials. Source: Rare Earth Technology Alliance.

Trends in North American Rare Earth Shipments

2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013

1200

1000

800

600

400

200

0

Millions ($)