news

industry

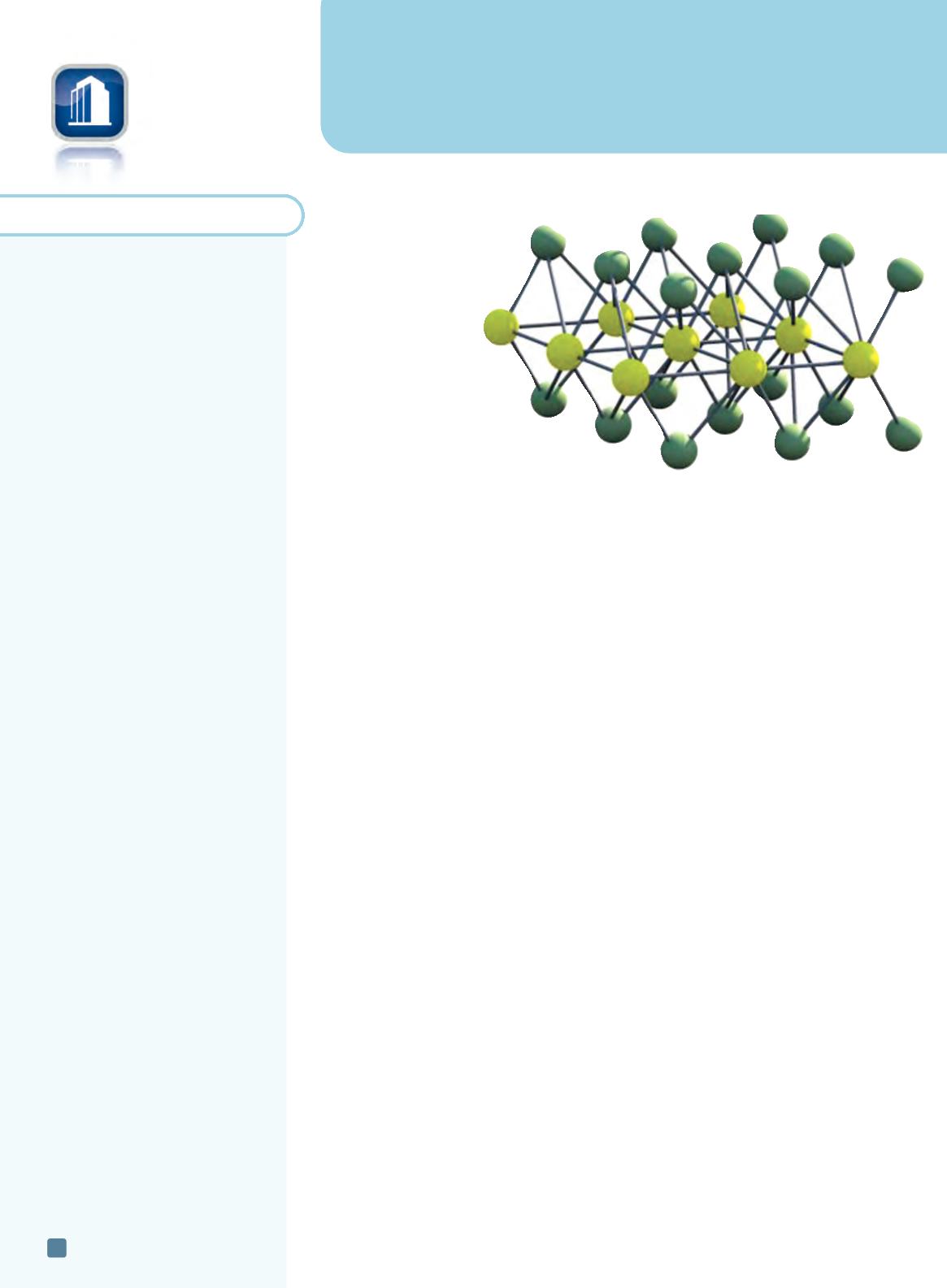

Making the thinnest solar cells

Researchers at Vienna Uni-

versity of Technology, Austria,

created a diode made of tung-

sten diselenide and experi-

ments show it could be

used to create ultrathin

flexible solar cells. Al-

though graphene is

often considered a wonder

material, it is not well suited

for building solar cells. “The

electronic states in graphene are

not practical for creating photovoltaics,”

says research leader Thomas Mueller. So he and his

team looked for other materials that can be arranged

in ultrathin layers but have better electronic properties.

They used tungsten diselenide, which consists of one layer of tungsten atoms connected

by selenium atoms above and below the tungsten plane. The material absorbs light, much

like graphene, but can be used to create electricity. The layer is so thin that 95% of the light

just passes through—but a tenth of the remaining 5%, which is absorbed by the material,

is converted into electrical power. A larger portion of the incident light can be used if sev-

eral of the ultrathin layers are stacked on top of each other—but sometimes high trans-

parency is a useful side effect. “We envision solar cell layers on glass facades, which let part

of the light into the building while at the same time creating electricity,” says Mueller.

For

more information: Thomas Mueller,

thomas.mueller@tuwien.ac.at, 43 1/58801-38739,

www.graphenelabs.at.

Discovery could lead to better electric vehicle batteries

An international research team led by Western University, Ontario, investigated elec-

tric batteries and battery materials to reveal an underlying mechanical interaction that oc-

curs during the carbon coating process. The coating not only affects the conductivity and

performance of battery materials, but also alters the chemistry of the battery material’s in-

teractive surface. Using advanced measuring techniques, including scanning electron mi-

croscope (SEM) imaging, researchers discovered that the surface of the LiFePO

4

battery

materials may actually melt during the heating process (at 600°-900°C), and that this phase

change is size-dependent.

“By carbon coating at a relatively high temperature, the surface of LiFePO

4

battery ma-

terials basically becomes a liquid, creating island-shaped phases or pockets on the top of

the battery materials, which breaks its conductivity,” explains Xueliang (Andy) Sun. He also

notes the discovery has yet to solve the problem of building better electric car batteries, but

understanding the surface chemistry greatly enhances the possibility to do so.

For more

information: Xueliang (Andy) Sun, 519/661-2111 ext. 87759,

xsun@eng.uwo.ca,

www.eng.uwo.ca.

Californium could be used to safely store radioactive waste

Californium is “wicked stuff,” according to Florida State University, Tallahassee,

professor Thomas Albrecht-Schmitt. In carefully choreographed experiments, re-

searchers found that californium had amazing abilities to bond and separate other

materials. It was also found to be extremely resistant to radiation damage. The discov-

eries could help scientists build new storage containers for radioactive waste, plus

help separate radioactive fuel, which means the fuel could be recycled.

For more in-

formation: Thomas Albrecht-Schmitt, 850/645-0477,

albrecht-schmitt@chem.fsu.edu,

www.fsu.edu.

ADVANCED MATERIALS & PROCESSES •

MAY 2014

16

E

NERGY

T

RENDS

briefs

ASTM International,

West

Conshohocken, Pa., introduced a

new standard—ASTM E2956 –

14—Standard Guide for Monitoring

the Neutron Exposure of LWR

Reactor Pressure Vessels. The USA

Code of Federal Regulations

requires a surveillance program for

all operating LWRs to monitor

changes in the fracture toughness

properties of ferritic materials in the

reactor vessel beltline, which result

from exposure to neutron irradiation

and the thermal environment. This

data is then used to determine the

appropriate safety conditions used

throughout the vessel’s life.

www.astm.org.

Researchers from

North Carolina

State University,

Raleigh,

developed a new processing

technique that makes LEDs brighter

and more resilient by coating the

semiconductor material gallium

nitride (GaN) with a layer of

phosphorus-derived acid.

Researchers started with polar GaN,

composed of alternating layers of

gallium and nitrogen. To increase

luminescence, the material’s

surface was etched with phosphoric

acid. Phosphonic groups that self-

assemble into a monolayer on the

surface were also added. This layer

further increases luminescence and

improves the stability of GaN by

making it less likely to react

chemically with its environment.

www.ncsu.edu.

A key patent from

3M,

St. Paul,

Minn., for lithium-ion battery nickel-

manganese-cobalt (NMC) cathode

technology emerged from

reexamination at the

U.S. Patent

and Trademark Office (USPTO)

with all original claims being

confirmed as patentable and with

no amendments (U.S. Patent

7,078,128). NMC cathode technology

is widely used in lithium-ion

batteries for consumer electronics

and electric vehicles. The patented

technology enables lithium-ion

battery makers to design electrodes

for specific applications for

optimum balance of power, energy,

stability, and cost.

www.3M.com.

Tungsten diselenide.

Courtesy of TU Vienna.