Fore! Glass golf clubs are playing through

What do some high-end golf clubs and a

living room window have in common? The

answer is glass, but the clubs use metallic

glass, which can be bent considerably and

spring back to original form. An interna-

tional team of scientists hopes their discov-

eries will lead to glass that is both stronger

and more ductile.

“We used an experimental technique

called nanoindentation to repeatedly sample

the initial formation of shear bands,” says Seth

Imhoff at Los Alamos National Laboratory,

N.M. “Essentially it uses a tiny needle to push

on the surface of a sample in a very controlled

way. Even though the force is small, the tip of

the needle concentrates stress in one small

region until a single shear band is generated

in order to relieve some stress.”

By repeating this process many times, scientists sample many local atomic arrange-

ments and their specific critical stress levels. This evidence challenges the current assump-

tion of only a single type of initiation site, or STZ (shear transformation zone).

Identification of multiple types of STZs could lead to new opportunities for controlling

the strength and ductility of bulk metallic glasses and, of course, more durable high-per-

formance golf clubs.

www.lanl.gov.Manufacturing a solution to planet-clogging plastics

Researchers at Harvard’s Wyss Insti-

tute, Boston, developed a method to carry

out large-scale manufacturing of every-

day objects—from cell phones to food

containers and toys—using a fully

degradable bioplastic isolated from

shrimp shells. The objects exhibit many

of the same properties as those created

with synthetic plastics, without the envi-

ronmental threat. It also trumps most

bioplastics on the market today in posing

no threat to trees or competition with the

food supply.

The bioplastic was developed from

chitosan, a form of chitin, a long-chain

polysaccharide responsible for the

hardy shells of shrimps and other crus-

taceans, armor-like insect cuticles,

tough fungal cell walls, and flexible but-

terfly wings. The majority of available

chitin in the world comes from dis-

carded shrimp shells, and is either

thrown away or used in fertilizers, cos-

metics, or dietary supplements.

The Wyss team, led by Javier Fernan-

dez and Don Ingber, developed a new way

to process the material so that it can be

news

industry

briefs

S

teelhead Composites,

Denver,

purchased and installed a heavy-

duty CNC neck forming machine

made by

MJC Engineering and

Technology,

Huntington Beach,

Calif. It is designed to manufacture

high-pressure cylinders, including

aluminum vessels to 42 cm (16.7

in.) in diameter and to 3 m (10 ft)

in length. A seamless aluminum

tube is shaped to form a bottle

with a domed end and port

openings. The bottle is then

wrapped with carbon fiber

composite using state-of-the-art

filament winding capabilities.

Composite overwrapped pressure

vessels are available as high

pressure, light weight gas storage

containers for high-pressure

compressed natural gas and

hydrogen, for example. The

machine can also manufacture

lightweight hydraulic

accumulators.

www.steelheadcomposites.com,

www.mjcengineering.com.

Exelis Inc.,

Salt Lake City, received

a contract worth more than $34

million from

Sikorsky Aircraft

Corp.

to produce major structural

airframe components for four

production-representative CH-53K

heavy lift helicopters. Designated

as system demonstration test

articles, the aircraft will enable the

U.S. Marine Corps to evaluate the

new helicopter system in 2017.

Exelis will fabricate and assemble

the composite sponsons, tail rotor

pylon, and horizontal stabilizer.

www.exelisinc.com,

www.sikorsky.com.

The first flight test CH-53K

aircraft being delivered for

evaluation. Courtesy of Sikorsky

Aircraft Corp.

M

ETALS

P

OLYMERS

C

ERAMICS

ADVANCED MATERIALS & PROCESSES •

MAY 2014

10

A piece of metallic glass was bent around

onto itself with a 1-mm radius and glued into

place. It would spring back to a flat piece if

the glue were removed.

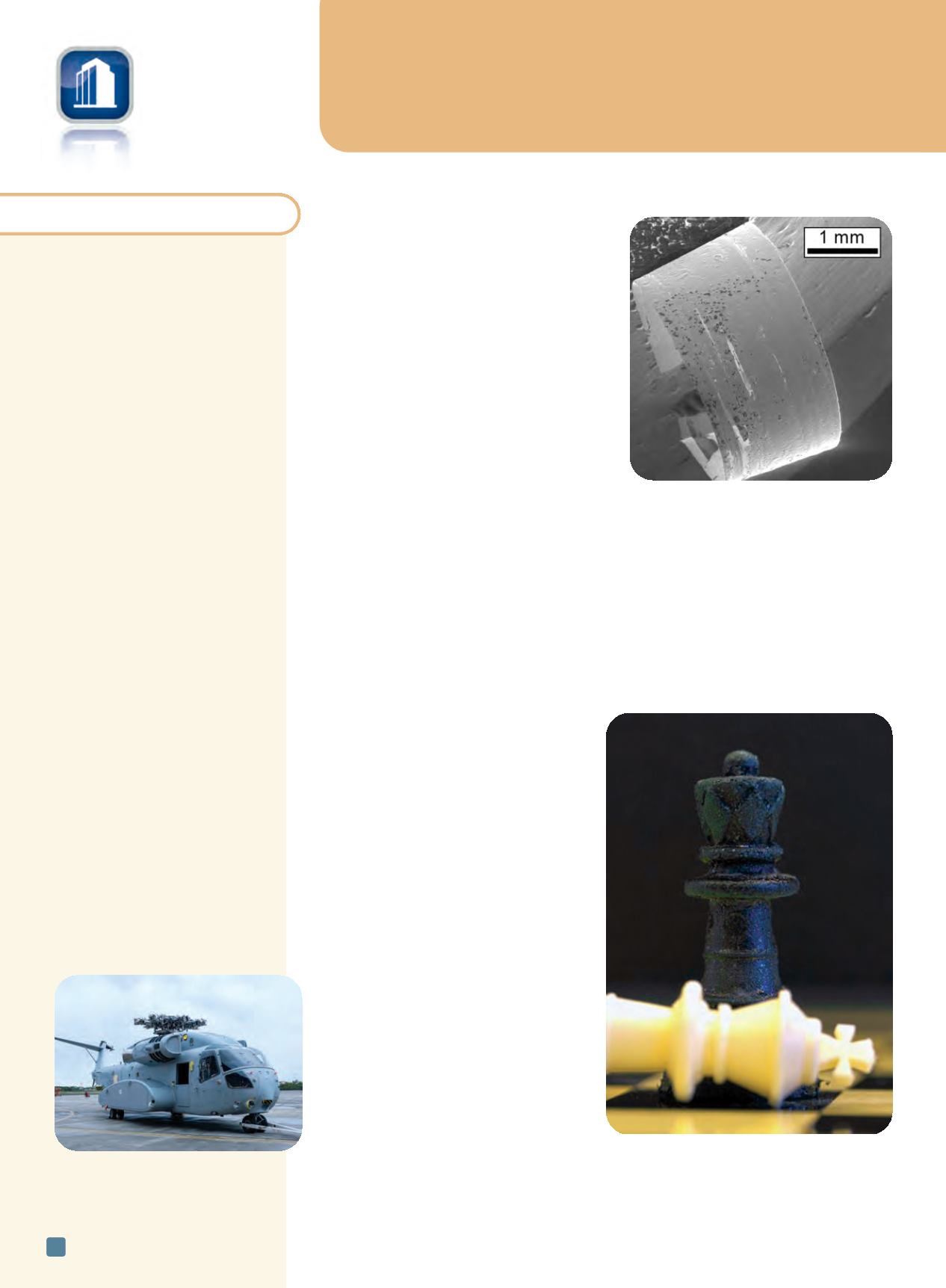

A series of chess pieces made of chitosan

bioplastic demonstrates a new way to

mass-manufacture large, 3D objects with

complex shapes made of fully compostable

materials. Courtesy of Harvard’s Wyss Institute.