60

Specimen Name:

NIST Center for Automotive Lightweighting (NCAL)

Vital Statistics:

Today’s automakers lack the necessary tools to easily

incorporate lightweight materials (e.g., aluminum alloys, high-

strength steels, and polymer composites) due to inadequate data

and material models. As a result, the U.S. auto industry spends

hundreds of millions of dollars per year reworking metal forming

dies that do not make correct parts.

NCAL is developing the measurement methodology,

standards, and analysis techniques required by auto

manufacturers and base metal suppliers to transition to advanced

materials for auto body components.

The center developed a technique to measure the stress-strain

response of sheet metal along nonlinear multiaxial paths. The

team also measures the sheet’s evolving crystallographic texture

to develop a microstructural understanding of deformation response.

Success Factors:

By directly measuring the mechanical

response of sheet metal being deformed along a

complex path, NCAL is providing the data

needed to develop next-generation models that

will accelerate the use of advanced lightweight

materials in vehicles. This high strain rate data helps ensure safe

performance in collisions and reduces the need for costly physical crash

tests, according to researchers.

Equipment includes a high-rate servohydraulic mechanical testing

machine; next-generation cruciform metal formability system

designed to test sheet metal along any path in strain space relevant to

metal forming operations; a Marciniak testing system with two

punch sizes, x-ray diffraction, and digital image correlation;

SEM, TEM, EBSD, XRD, OIM, optical and neutron diffraction;

computational facilities; and a sample preparation area that

includes plasma cutting and welding.

About the Innovators:

NCAL is led by Tim Foecke and NIST researchers Mark

Iadicola, Thomas Gnaeupel-Herold, Adam Creuziger, Bill Luecke,

Dave Pitchure, and Mark Stoudt. Consortium partners include

Ford, General Motors, Chrysler, ThyssenKrupp, US Steel Corp.,

ALCOA, Carnegie Mellon University, and several others.

What’s Next:

Beyond model generation, there is ongoing work to measure the actual

stress-strain state within the neck of an ASTM E-8 tensile specimen to

determine mechanical properties beyond instability. This high strain data

helps forming simulations, as the constrained deformation during forming

often exceeds that reached by traditional tensile tests.

Contact Details:

Tim Foecke, NCAL Director

NIST Material Measurem

ent Laboratory10

0 Bureau Dr., Gaithersburg, MD 20899-8553

301/975-6592,

timothy.foecke@nist.gov, www.nist.gov/lightweighting

Close-up of x-ray stress measurement

mounted on the cruciform system,

positioned above a deforming sample.

SucceSS AnAlySiS

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

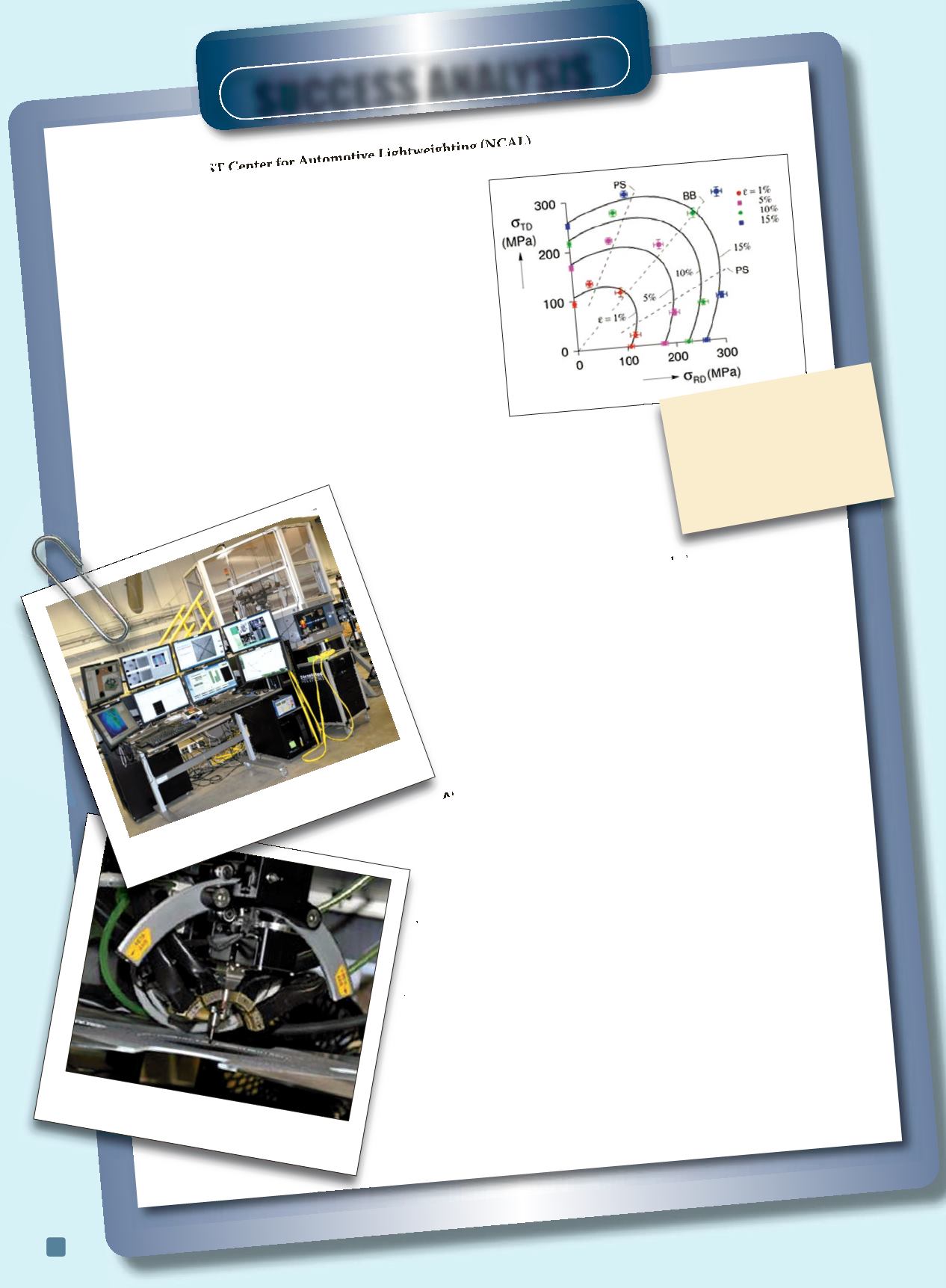

For the first time, the

tensile multiaxial yield

surface of 5754 aluminum

alloy sheet was measured

from initial yield up to

failure. Graph shows the

flow stress of 5754 Al

as a function of strain.

Control center and overview of NCAL’s

metal formability system.