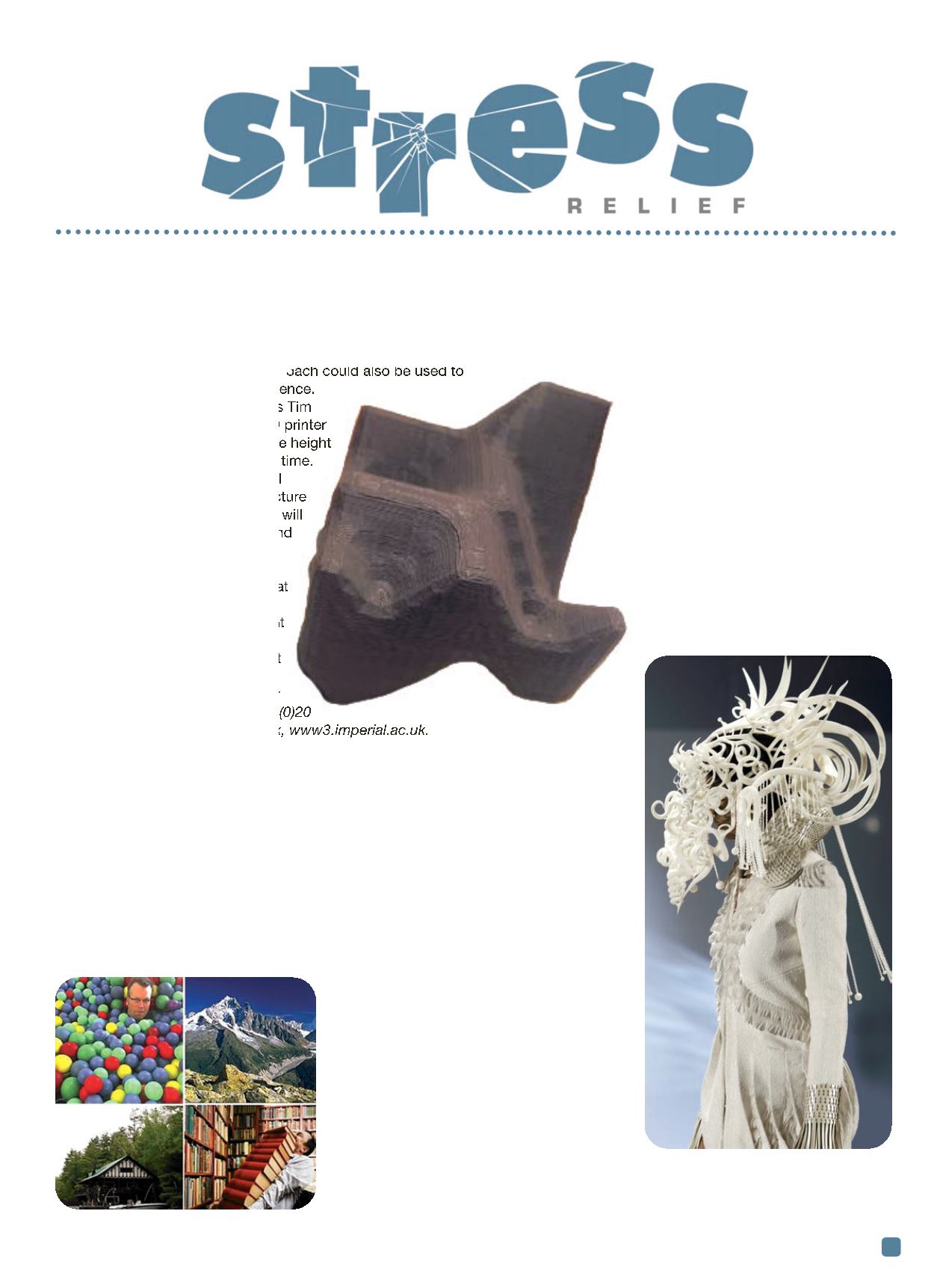

3D printing explains physics

Researchers at Imperial College London successfully demonstrated how complex

theoretical physics can be transformed into a physical object using a 3D printer. In

eight hours and at the cost of around $20 (15€), a commercially available 3D printer

created 8-cm

3

objects based on a mathematical model that describes how forest fires

can be started and how they eventually spread over time. Dubbed “sculplexity”

(sculptures of complexity), the approach could also be used to

produce works of art based on science.

“The basic idea is simple,” says Tim

Evans, theoretical physicist. “A 3D printer

builds up its object in layers, so the height

of the object can be thought of as time.

Suppose you have a mathematical

model, which defines a flat, 2D picture

that evolves in time—typically this will

be a grid with some squares full and

some empty. The mathematical

model will define at each point in

time what the printer should print at

one height. The next step in the

model will then define what to print

on top of the first layer, and so

forth. The result is a 3D object that

shows how the mathematical

model has evolved over time.”

For

more information: Tim Evans, +44 (0)20

7594 7837,

t.evans@imperial.ac.uk,

www3.imperial.ac.uk.

ADVANCED MATERIALS & PROCESSES •

MARCH 2014

59

Wearable art

Chicago-based artist and

longtime proponent of 3D-printed art

and sculpture, Joshua Harker made

his runway debut at this year’s 3D

Printshow in London and Paris. His

first piece of wearable art, a

headdress laser sintered on an

EOSINT P 760 additive

manufacturing system, served as the

anchor of the fashion show. The all-

plastic headgear, which pays homage

to traditional ceremonial headdresses

of Native American and African

tribes, consists of a variety of

interwoven and suspended

components. After Harker dedicated

almost 200 hours of design time,

EOS was able to print the entire

piece in less than 26 hours.

For more

information: Joshua Harker, 773/343-

2251,

josh@joshharker.com.

Algorithm makes faces more memorable

Faces could be instantly transformed into more

memorable ones without the need for an expensive

makeover, thanks to an algorithm developed by

researchers in Massachusetts Institute of Technology’s

Computer Science and Artificial Intelligence Laboratory, Cambridge. To develop the

algorithm, a database of more than 2000 images was fed into the software. Each

image was awarded a “memorability score,” based on volunteers’ ability to remember

the pictures, which allows the software to analyze and detect subtle trends in the

features that made them more or less memorable. The algorithm was programmed

with a set of objectives—to make the face as memorable as possible without

changing the identity of the person or

altering their facial attributes, such as age,

gender, or overall attractiveness.

Changing the width of a nose may make a

face look much more distinctive, for

example, but it could also completely alter

how attractive the person is, and so would

fail to meet the algorithm’s objectives.

For more information: Aditya Khosla,

khosla@csail.mit.edu,

www.web.mit.edu.

The top left and bottom right images are the

most memorable. Courtesy of the Oliva and

Torralba labs.

The headdress material is nylon 12

(specifically EOS PA 2201), commonly

used in manufacturing. Its properties are

analogous to traditional nylon 12.

Researchers successfully

demonstrated how

complex theoretical

physics can be

transformed into a physical

object using a 3D printer.

Courtesy of Imperial

College London/EPL.