A D V A N C E D M A T E R I A L S & P R O C E S S E S | J A N U A R Y 2 0 1 7

5 2

3D PRINTSHOP

THE SOUNDOF SILENCE

Inspired by feathers that suppress

flight sound, researchers developed a

3D-printed plastic attachment that can

be retrofitted to an existing airfoil design

to reduce wind turbine noise. The sci-

entists—from Lehigh University, Virginia

Tech, Florida Atlantic University, and the

University of Cambridge—modeled their

device on down from owl wings. The

down consists of hairs that rise almost

perpendicular to the feather surface,

then bend in the flow direction to form

a canopy at the top like a microscopic

forest. The canopy pushes off the noisy

air flow, suppressing frequencies over

1.6 kHz—including the range of greatest

sensitivity in human hearing. To mimic

this structure, the device consists of

small “finlets,” which can reduce turbine

noise by 10 dB without affecting aerody-

namics. This kind of noise reduction has

implications beyond wind turbines and

aircraft, and could be applied to other

aerodynamic situations such as wind

noise in automobiles.

lehigh.edu, vt.edu,

fau.edu,

www.cam.ac.uk.

GE INITIATIVE ADDS ON

GE, Fairfield, Conn., will purchase

controlling shares of Arcam AB, Swe-

den, inventor of electron beam melting

machines for metal-based additive man-

ufacturing and a producer of metal pow-

ders for the aerospace and orthopedic

industries. Arcam also operates AP&C,

Canada, a metal powders operation, and

DiSanto Technology, Shelton, Conn., a

medical additivemanufacturing (AM) firm,

in addition to sales and application sites

worldwide. The purchase comes on the

heels of GE’s $599 million acquisition of a

75% stake in Concept Laser GmbH, Ger-

many, which designs and manufactures

powder bed-base laser AM machines for

the aerospace, medical, and automotive

industries, among others. Concept Laser

processes powdermaterials including tita-

nium, nickel-base, and cobalt-chromium

alloys, as well as hot-work and high-grade

steels and aluminum. The recent acqui-

sitions dovetail with GE’s ongoing AM

efforts, which include a $1.5 billion invest-

ment in manufacturing and additive tech-

nologies at their Global Research Center

and the development of a worldwide net-

work of centers for advancing AM science.

geadditive.com.

PRINTING PREVAILS IN

MAGNET MANUFACTURE

Scientists at the DOE’s Oak Ridge

National Laboratory (ORNL), Tenn.,

demonstrated that additive manufac-

turing (AM) can produce permanent

magnets with mechanical, microstruc-

tural, and magnetic properties superior

to those of bonded magnets made

using traditional methods—all while

conserving critical materials. To fabri-

cate the isotropic, near-net-shape, neo-

dymium-iron-boron bonded magnets,

the Oak Ridge team began with com-

posite pellets made of 65 vol% isotro-

pic NdFeB powder and 35% polyamide

(Nylon-12), then melted, compounded,

and extruded them using the Big Area

Additive Manufacturing machine. While

conventional sintered magnet manu-

facturing can result in material waste of

30-50%, AM reuses that material, pro-

ducing nearly zero waste, an especially

important factor when manufacturing

magnets with neodymium and dyspro-

sium—rare earth elements mined and

separated outside the U.S. AM is also

more efficient than traditional injection

methods. “Manufacturing is changing

rapidly, and a customer may need 50 dif-

ferent designs for themagnets they want

to use,” explains researcher Ling Li. AM

allows eachmagnet to be crafted quickly

using computer-assisted design instead

of requiring individual mold making and

tooling

. ornl.gov.Feathers from (a, b) Eurasian eagle owl,

(c) great gray owl, and (d) snowy owl.

Courtesy of Ian A. Clark, et al.

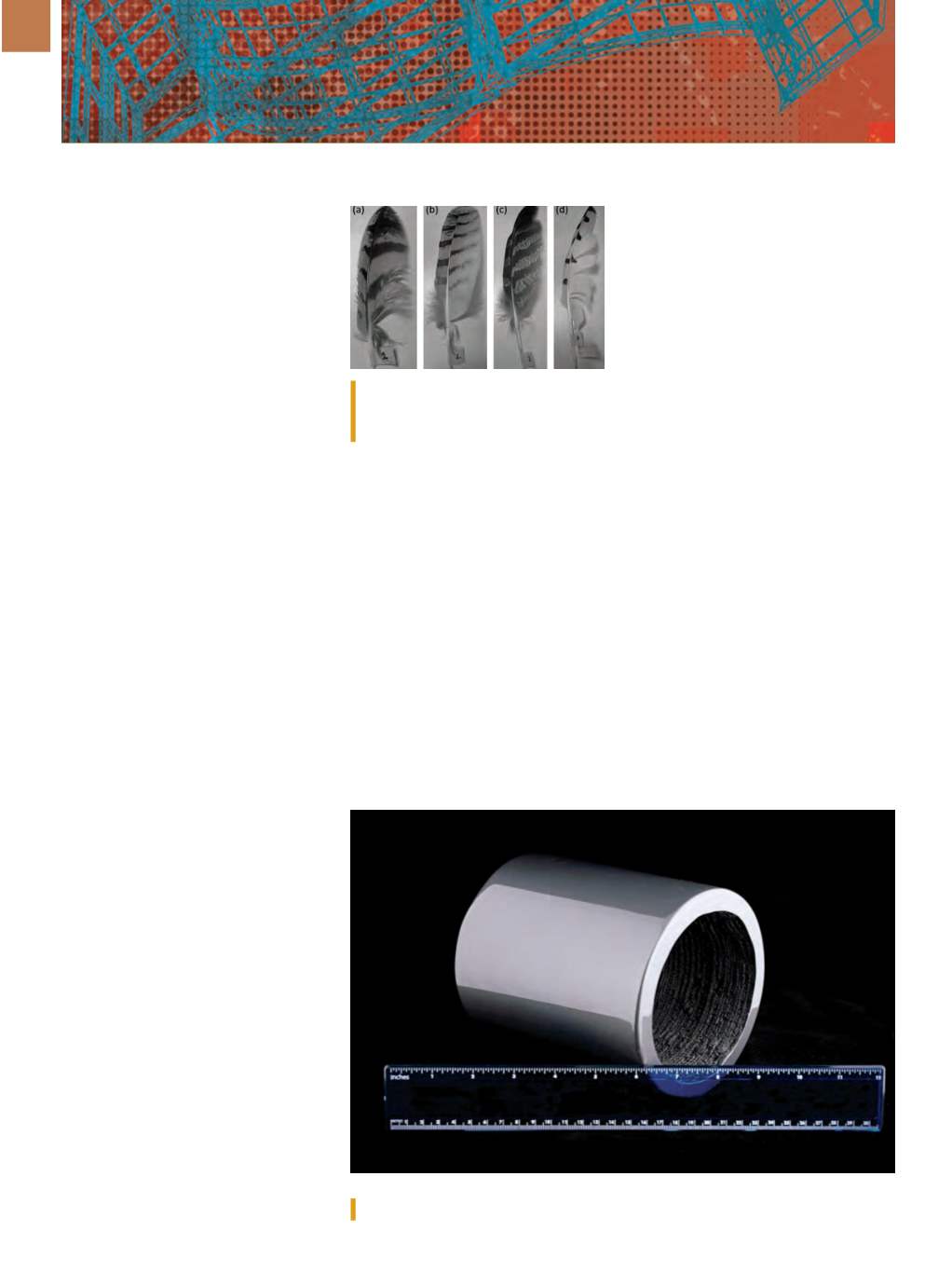

This isotropic, NdFeB bonded permanent magnet was 3D-printed at ORNL.