6 0

A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

3D PRINTSHOP

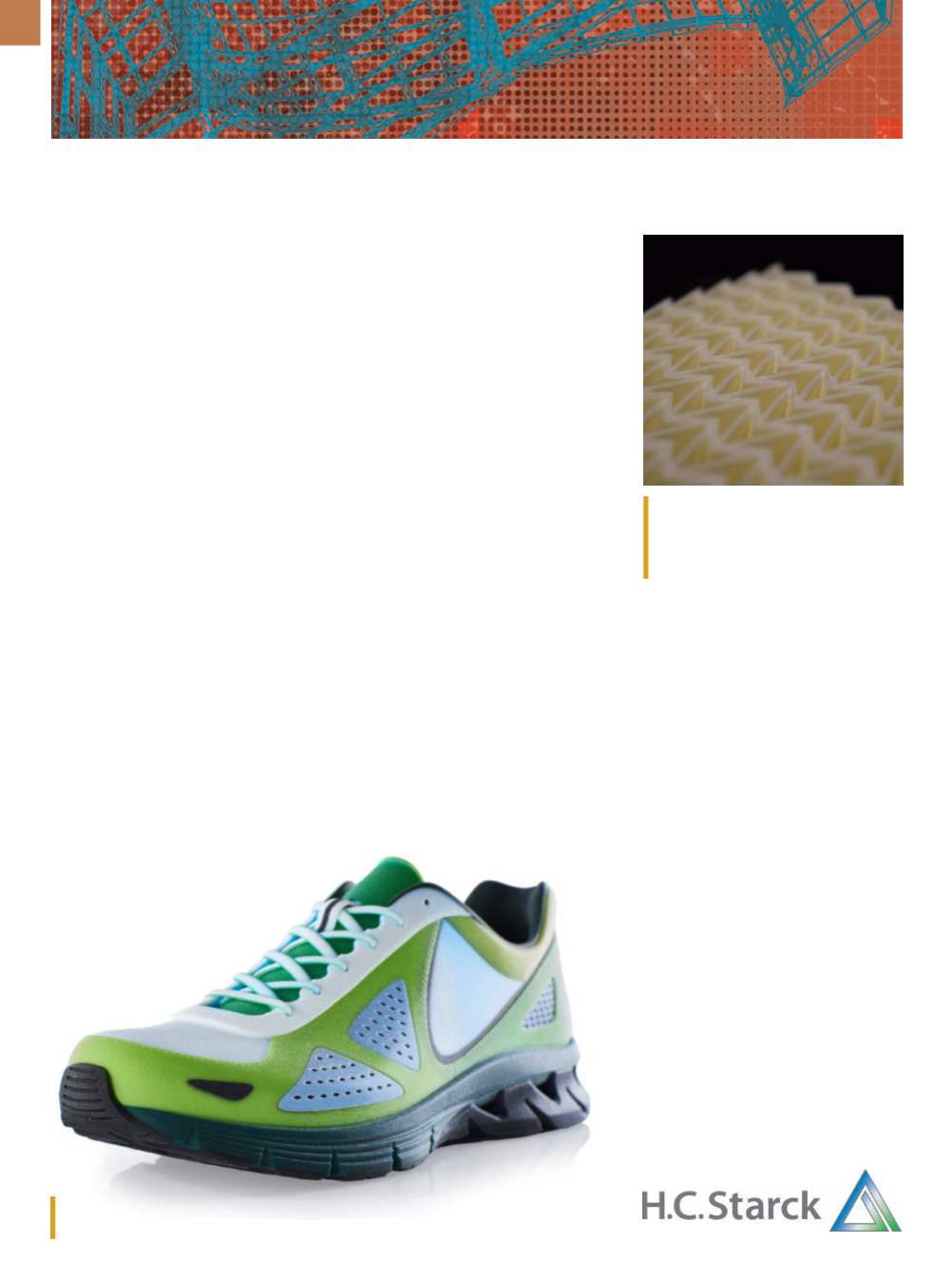

ONE-STOP PRINTER BUILDS COMPLETE ATHLETICSHOE

Prototype produced with full color, smooth surfaces, and a rubberlike sole, all in a single print

operation. Courtesy of Business Wire and Stratasys Ltd.

S

tratasys Ltd., Minneapolis, intro-

duced the J750 3D printer that

produces finished models with

colors, textures, andmultiple materials,

eliminating the need for post-process-

ing. For example, the J750 can print a

complete athletic shoe with full color,

smooth surfaces, and a rubberlike sole

in a single operation. Built-in PolyJet

Studio software is newly designed and

allows users to mix and match more

than 360,000 different colors plus mul-

tiple materials and material proper-

ties—from rigid to flexible and opaque

to transparent. Color textures can be

loaded intact via VRML files imported

from CAD tools.

The machine also offers increased

efficiency over previous models. Its

six-material capacity keeps the most

used resins loaded and ready for print-

ing, while newly designed print heads

allow simulated production plastics

such as Digital ABS to be printed in half

the time of other Stratasys PolyJet sys-

tems. Finally, the J750 is expected to

improve total cost of ownership. Design-

ers and engineers can handle product

prototypes within hours of developing

an initial concept and receive immediate

feedback, eliminating processes, time,

and resources typically required to cre-

ate product-matching prototypes.

stratasys.com.

NOVEL MATERIAL BOOSTS

BRAIN PROTECTION

Helmet manufacturer Charles

Owen Inc., Lincolnton, Ga., was

awarded $250,000 to develop a new,

energy absorbing material that could

protect athletes and military person-

nel, among others, from brain injury.

The prize will support a collaboration

between the company, which produces

equestrian, motorcycle, and military

helmets, and Cardiff University, UK, cre-

ator of the multilayered, elastic mate-

rial called C3. The project will further

develop the material, which can be

precisely designed using mathemati-

cal modeling, and then computer test

it for specific impact scenarios prior to

fabrication with a 3D printer. During C3

production, a polymer-based powder

is fused into a specific shape by a laser,

which solidifies the material to form a

strong, flexible structure.

Funding was awarded by a part-

nership of the National Football League,

Under Armour, GE, and the National

Institute of Standards and Technology

as part of

Head Health Challenge III:

Advanced Materials for Impact Mitiga-

tion.

The team is among four winners

to secure initial funding; after a year,

the most promising technology will

receive another $500,000 to support

further development.

charlesowen.com,

www.cardiff.ac.uk.

POWDER PROCESS POWERS

UP FOR AM

H.C. Starck, Germany, launched

a new process to produce specialized

refractory metal powders for additive

manufacturing (AM). The company

will apply the new process to its exist-

ing products—molybdenum, tanta-

lum, niobium, and tungsten in pure

and alloyed powder forms—offering

spheroidized refractory metal powders

with tailored chemistry and particle

size distribution. The new powders are

engineered for enhanced processability

and performance when used with stan-

dard AM techniques such as binder jet,

directed energy deposition, and pow-

der bed fusion.

hcstarck.com.

C3 material can be designed using

mathematical modeling and tailored for

specific impact scenarios. Courtesy of

Cardiff University.