A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 6

1 2

TESTING | CHARACTERIZATION

polyimide tape through the cavity, the

change in resonance frequency corre-

sponded to the tape’s thickness.

Because polyimide’s electrical

properties are well known, this method

of cavity resonance could be used on

production lines to monitor whether or

not tape is being produced at a consis-

tent thickness. Real-time testing could

be used to tune the manufacturing

process without shutting it down or to

discard faulty product before it leaves

the factory. The entire product—not

just a sample—can be measured, and

because the method is nondestructive,

a batch that passes the test could be

sold.

nist.gov.HANDHELD NANOFIBER

SCANNER SEEKS LEAKS

Engineers at the University of

Utah, Salt Lake City, developed a fiber

composite material for a handheld

scanner that can detect small traces

of alkane fuel vapor, an odorless and

colorless ingredient in combustible

materials such as airplane fuel and oil.

The composite contains two nanofibers

that transfer electrons to each other.

When alkane is present, it blocks the

electron transfer, alerting the scanner.

Until now, there has been no way to

sniff out alkane in the field. Detection

required an oven-sized instrument in

a lab. Uses for the new device include

early leak detection on oil pipelines

and aircraft fuel tanks as well as secu-

rity applications. Many homemade

explosives, such as those used in the

REAL-TIME RESONANCE

TESTING ON A ROLL

Physicists at the National Institute

of Standards and Technology (NIST),

Gaithersburg, Md., developed a fast,

nondestructive testing method for roll-

to-roll manufacturing that can be used

in real-world conditions. A roll-to-roll

setup was used to run a strip of polyim-

ide plastic tape through a microwave

cavity. Electromagnetic waves build

up inside the metal cavity at a specific

resonance frequency determined by its

dimensions, but when an object enters

the cavity, the resonance frequency

changes according to the object’s size,

electrical resistance, and dielectric

constant. When researchers passed the

Thermo Fisher Scientific,

Tewks-

bury, Mass., acquired

Inel Inc.,

France, a provider of real-time x-ray

diffraction systems. The business

will be integrated into Thermo

Fisher’s analytical instruments

segment.

thermofisher.com.

Ceralink Inc.,

Saint Clairsville,

Ohio, expanded its materials test-

ing lab and will serve the aerospace

industry’s metal testing programs,

putting 16 new MTS Landmark

Generation test frames to work on

metals.

ceralink.com.

Zwick/Roell AG,

Germany, will

supply 19 testing systems to

Sapa

Extrusions North America,

Rose-

mont, Ill., an aluminum extrusion

producer. Sapa recently conducted

an internal audit of its North Amer-

ican tensile testing labs to enhance

product quality and standardize

testing procedures.

zwick.com,

sapagroup.com.

BRIEFS

The founders of

Jeol Ltd.,

Peabody, Mass., were hon-

ored at Pittcon 2016, held during March in Atlanta. The

Pittcon Heritage Award was presented to Gon-emon

Kurihara, Jeol president, “In recognition of their sci-

entific vision and pioneering leadership, directing the

post-World War II effort in Japan to build an electron

microscope and founding one of the greatest Japa-

nese instrumentation companies.”

jeolusa.com.

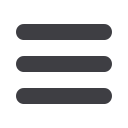

Electrical property measurements of a plastic tape (yellow) were taken using a

specially designedmicrowave cavity (white cylinder at center) and accompanying

electrical circuit. Courtesy of N. Orloff/NIST.

From left, Carsten Reinhardt,

Gon-emon Kurihara, and

William Sharpe. Courtesy

of Roy Engelbrecht.