A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 6

1 0

METALS | POLYMERS | CERAMICS

through surface environments,” says

Frank Reith, at the University of Ade-

laide’s School of Biological Sciences

and visiting researcher at CSIRO Land

and Water, both in Australia. “This re-

search reveals the key role of bacteria

in these processes. This improved bio-

geochemical understanding is not only

important from a scientific perspective,

but we hope will also lead to new and

better ways of exploring these metals.”

“Traditionally it was thought that

these platinum group metals only

formed under high pressure and tem-

perature systems deep underground,

and that when they were brought to

the surface through weathering and

uplift, they just sat there and noth-

ing further happened to them,” says

Reith. “We’ve shown that is far from the

case. We’ve linked specialized bacterial

ORNL’s tough new plastic is made with 50% renewable content frombiomass.

Courtesy of ORNL. Conceptual art by Mark Robbins.

ConstelliumN.V.,

Amsterdam,

signed a contract with

Airbus,

France. Under the new agreement,

Constelliumwill supply Airbus with a

broad range of advanced aluminum

rolled products for airframes includ-

ing wing skin panels, aero-sheets for

fuselage panels, as well as rectan-

gular and pre-machined plates for

structural components

. constellium. com, airbus.com.

Dutch startup

Eurekite

developed

a new kind of ceramic, one that

is both flexible and easily made

at varying degrees of thickness.

The company, affiliated with the

University of Twente in the Neth-

erlands, is initially marketing the

new product as a replacement for

traditional printed circuit board

materials.

eurekite.com.

BRIEFS

Alcoa Inc.,

Pittsburgh, received a

five-year contract from the

U.S. Army

worth up to $50 million for R&D projects

focused on developing lightweighting

solutions for ground combat vehicles,

such as the monolithic hull for combat

vehicles shown here.

alcoa.com,

tardec. army.mil.

RENEWABLE MATERIALS MAKE

STRONGER PLASTIC

Researchers at the Department of

Energy’s Oak Ridge National Laboratory,

Tenn., made a better thermoplastic by

replacing styrene with lignin, a brittle,

rigid polymer that, with cellulose, forms

the woody cell walls of plants. In doing

so, they invented a solvent-free produc-

tion process that interconnects equal

parts of nanoscale lignin dispersed in

a synthetic rubber matrix to produce a

meltable, moldable, ductile material at

least 10 times tougher than acryloni-

trile, butadiene, and styrene (ABS). The

resulting thermoplastic—called ABL for

acrylonitrile, butadiene, lignin—is recy-

clable, as it can be melted three times

and still performwell.

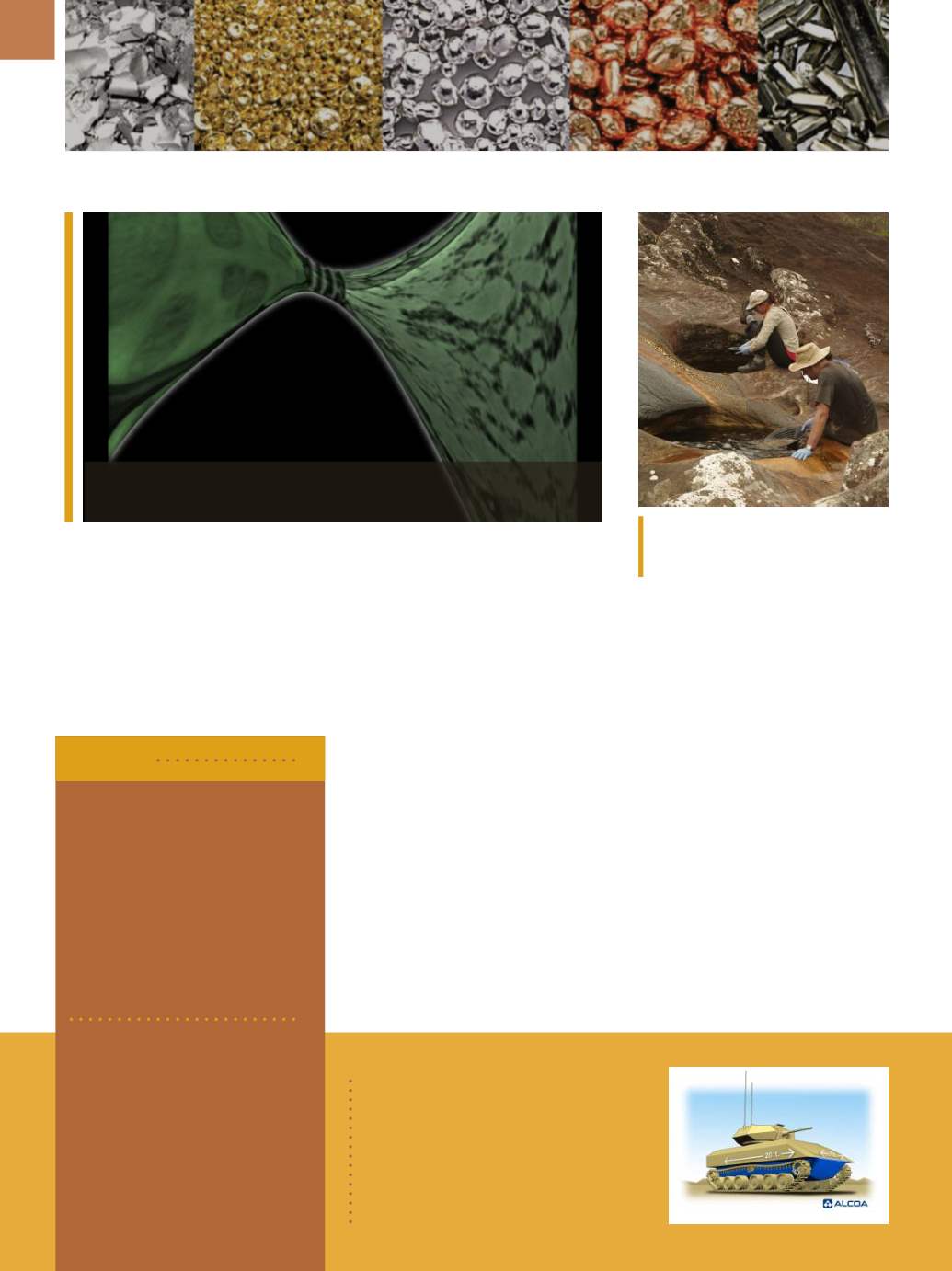

ornl.gov.BACTERIA HELPS

PLATINUM FORM

Scientists uncovered the import-

ant role of specialist bacteria in the

formation and movement of plati-

num and related metals in surface en-

vironments. “These platinum group

elements are strategically important

metals, but finding new deposits is be-

coming increasingly difficult due to our

limited understanding of the process-

es that affect the way they are cycled

Panning for platinum grains in Brazil:

Frank Reith and Barbara Etschmann.

Courtesy of University of Adelaide.