A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 5

3 5

Metals.

Hoyt describes Merica’s appear-

ance when he arrived: “One day a young

man presented himself at the laboratory

and announced he might be joining us.

His attitude seemed to say that he might

just possibly if he liked what he saw. He

wore a straw hat obviously too small

worn on the side of his head.” Merica and

Hoyt had a number of classes together

including one taught by Adolf Marten for

whom Floris Osmond named martensite

after. Here they met Guillaume Kroll,

also known as William Kroll of titanium

fame.

Upon his return, now with a Ph.D.

in physics and metallurgy, Merica

worked for a brief time at the University

of Illinois. He then joined the National

Bureau of Standards where he worked

for an older physicist and metallurgist,

George Burgess, a Massachusetts Insti-

tute of Technology graduate who also

studied under the famous Henry-Louis

Le Chatelier at the Sorbonne in Paris.

Merica led a group of metallurgists in

studying the mechanism responsible

for age hardening in duralumin. His

colleagues included Howard Scott, R.G.

Walthenberg, and J.B. Freeman.

DURALUMIN RESEARCH

PROGRAM

The Bureau’s study was designed

to examine the role of Cu and Mg in-

dependently and then combine them

in various amounts to determine how

they interacted to cause age harden-

ing. Sample alloys were made at the

New Kensington plant of the Aluminum

Company of America. They were rolled,

annealed, and rerolled until reduced to

a 0.032-in. thickness in the cold-rolled

condition. They were tested in the cold-

rolled condition and after annealing to

soften them to form a baseline mea-

surement. Other samples were solu-

tion-treated at temperatures to 520°C,

water-quenched to room temperature,

and aged for 11 days at room tempera-

ture or for three days at 100°C. All sam-

ples were tested for hardness, ultimate

tensile strength, and elongation.

Merica and his team concluded

that this supersaturated solid solution

formed a pre-precipitate that hindered

plastic deformation until higher stress

was applied to the material. Over-

aging at higher temperatures where

CuAl

2

could be seen removed the pre-

precipitate, and alsodecreasedhardness.

The work showed that duralumin might

not be unique, but amechanism for hard-

ening in other alloy systems fitting the

conclusions of Merica. Any alloy with de-

creasing solid solubility with decreasing

temperature when quenched to form a

supersaturated solid solution could form

pre-precipitates at some aging tempera-

ture. The authors stated, “If the tempera-

ture of the alloy is raised to 100°C, or even

to ordinary room temperature, according

to the theory which the authors propose,

the mobility of the molecules becomes

sufficiently great that precipitation of the

CuAl

2

takes place in the form of very fine

particles of colloidal dispersion.”

The authors finally concluded,

“Upon aging a quenched sample at

200°C, the hardness first increases to a

maximum and afterwards decreases.

During that aging there has been first a

formation of fine nuclei of CuAl

2

followed

by coalescence of these particles into

ones of larger size. There is, therefore, a

certain average size of particle of CuAl

2

for which the hardness is a maximum;

atomic dispersion of the solute is not the

dispersion that produces the maximum

hardness but some intermediate one be-

tween it and that at which the particles

become visible by ordinary means. To

this dispersion is due the hardening of

duralumin.”

Results of this study by Paul Dyer

Merica, et al., were quoted by Zay Jef-

feries as “the shot heard around the

world.” If duralumin could be hardened

by precipitation of a compound, then

this new hardening mechanism could be

applied tomany other alloy systems. The

resulting developments opened the door

to a whole newworld of strong alloys.

AWARDS AND HONORS

Merica received many awards for

his work on precipitation hardening in

duralumin including the John Fritz Med-

al, the Platinum Medal from the British

Institute of Metals, ASM’s Gold Medal,

The Franklin Institute’s Franklin Medal,

and AIME’s James Douglas Gold Medal.

Merica joined the International Nick-

el Co. in 1919 after his five years at the

National Bureau of Standards. During

the next 38 years, he advanced from re-

search metallurgist to president of the

parent company, the largest nickel com-

pany in the western world. Merica died

of a heart attack in 1957 at the age of 68.

For more information:

Charles R.

Simcoe can be reached at

crsimcoe1@ gmail.com.

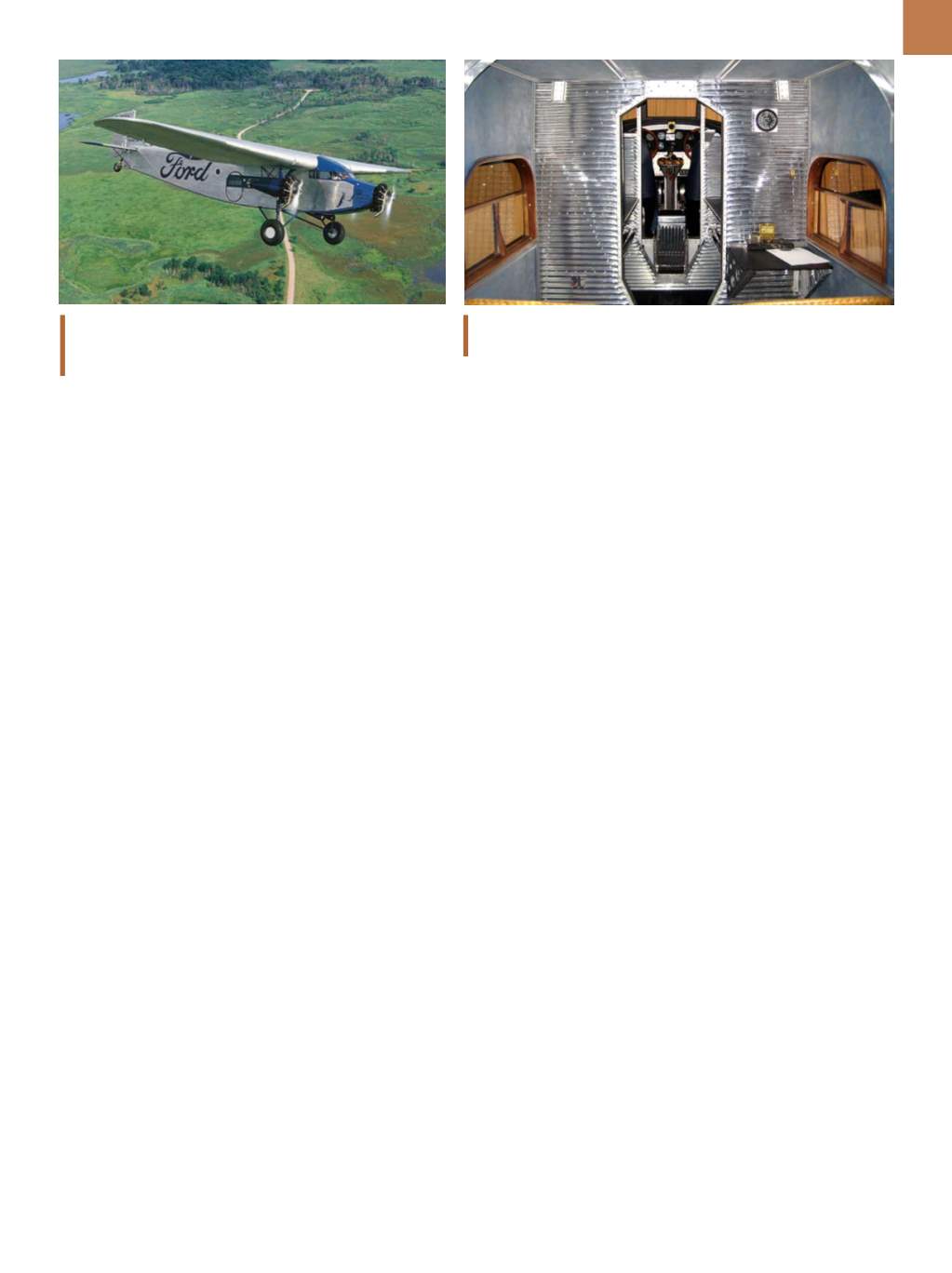

The Ford Trimotor was the first commercial plane built in the

U.S. with a duralumin type alloy produced by Alcoa. Courtesy

of

goldenwingsmuseum.com.

Interior of the Trimotor, which only held a dozen passengers. Courtesy of

goldenwingsmuseum.com.