6

MARKET SPOTLIGHT

FEEDBACK

A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 5

REPORT ASSESSES CRITICALITY OF

ALL METALS ON PERIODIC TABLE

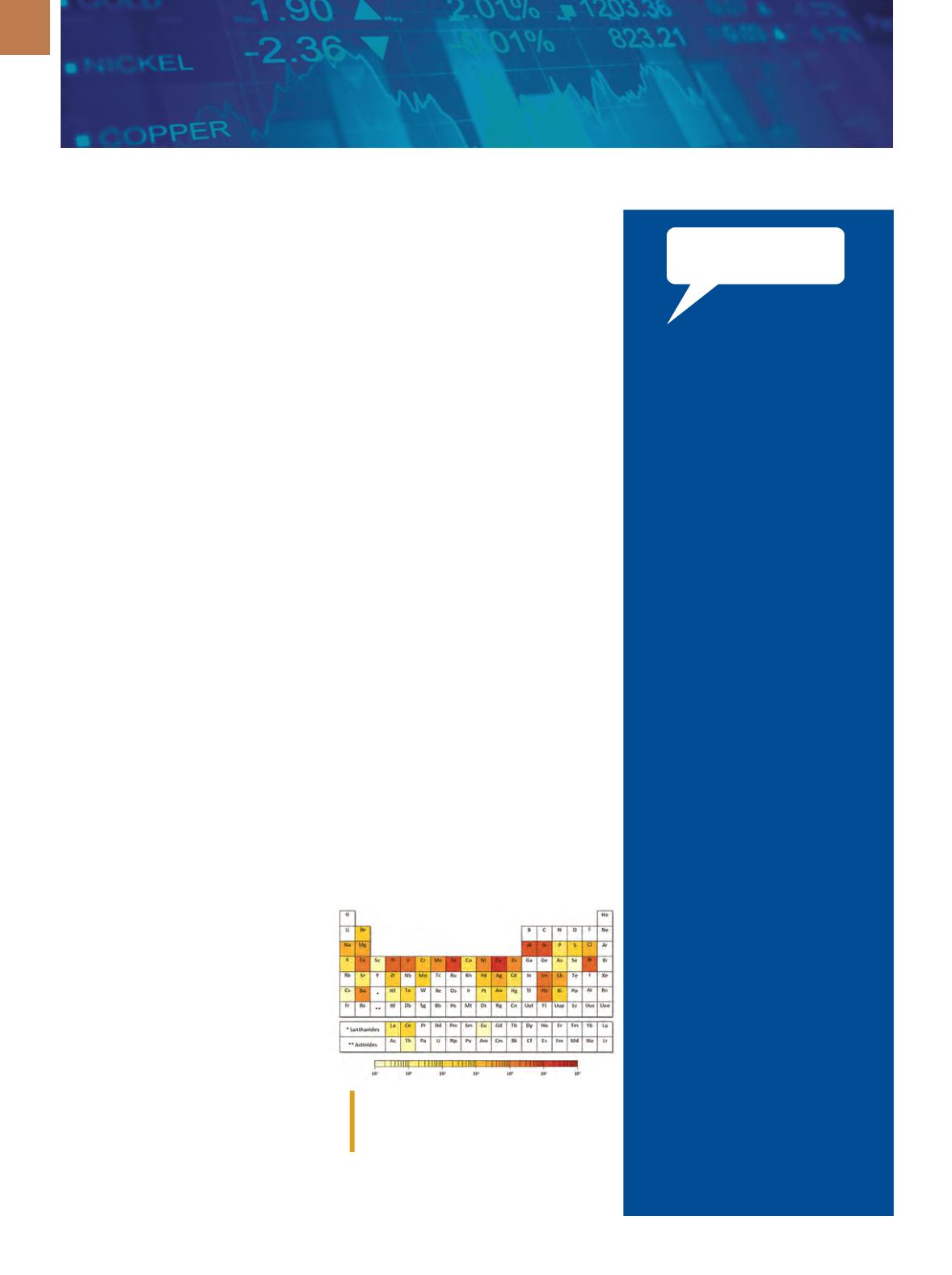

In a new report, researchers from

Yale University, New Haven, Conn., as-

sess the criticality of all 62 metals on the

periodic table, providing key insights

into which materials might become

more difficult to find in the coming de-

cades, which ones will exact the highest

environmental costs, and which ones

cannot be replaced as components of

vital technologies. Many of the metals

traditionally used in manufacturing,

such as zinc, copper, and aluminum,

show no signs of vulnerability. But oth-

er metals critical to the production of

newer technologies like smartphones

may be harder to obtain in coming

decades, says Thomas Graedel, pro-

fessor of industrial ecology at the Yale

School of Forestry & Environmental

Studies. The study represents the first

peer-reviewed assessment of the crit-

icality of all of the planet’s metals and

metalloids.

“The metals we’ve been using for a

long time probably won’t present much

of a challenge,” says Graedel. “But

some metals that have been deployed

for technology only in the last 10 or 20

years are available almost entirely as

byproducts. You can’t mine them spe-

cifically and they don’t have any decent

substitutes.”

According to researchers, critical-

ity depends on more than geological

abundance. Other factors include the

potential for finding effective alter-

natives in production processes, the

degree to which ore deposits are geo-

politically concentrated, the state of

mining technology, regulatory over-

sight, geopolitical initiatives, regional

instabilities, and economic policies.

In order to assess the state of all met-

als, researchers looked at supply risk,

environmental implications, and vul-

nerability to human-imposed supply

restrictions.

Supply limits for many metals crit-

ical to the emerging electronics sector

(including gallium and selenium) are

the result of supply risks. Environmen-

tal implications of mining and process-

ing present the greatest challenges

with platinum-group metals, gold, and

mercury. For steel alloying elements

(including chromium and niobium) and

elements used in high-temperature al-

loys (tungsten and molybdenum), the

greatest vulnerabilities are associated

with supply restrictions.

Among the factors contributing

to criticality challenges are high geo-

political concentration of primary pro-

duction, lack of available substitutes,

and political instability. For example, a

significant portion of tantalum, wide-

ly used in electronics, comes from the

war-ravaged Democratic Republic of

the Congo.

For more information, visit

environment.yale.edu.Yousay ALUMINUM,

I say ALUMINIUM

I recently read the two historical

articles on the Hall-Heroult process

used to make aluminium (“Metallur-

gy Lane,” September and October

2014). It was particularly interesting

to read about Charles Hall’s devel-

opmental work and the evolution of

the appropriately named Pittsburgh

Reduction Co. I did a literature search

several years ago and found that the

word for the element stems from its

presence in the mineral alum. Refin-

ing of the ore produced a derivative

of its name—alumina. The reduction

process resulted in what was initially

called aluminum.

Then, in the late 19th century,

an agreement was reached with the

predecessor of the International

Union of Pure and Applied Chemistry

to add the letter “i” to its name to

bring its spelling into line with the

other elements, e.g., helium, lithium,

and sodium. The icing on the cake to

the “Metallurgy Lane” articles would

have been to answer the question of

why the American Chemical Society,

in 1927, reverted to the 19th century

name for aluminium, i.e., aluminum.

Tony Wells, Australia

[Attention metal history buffs:

If you have a theory or an answer

to this naming puzzle, please drop

us a line.—Eds.]

We welcome all comments and

suggestions. Send letters to

frances. richards@asminternational.org.

Concentrations (in parts per million)

of elements on a printed circuit board.

Courtesy of Thomas Graedel, et al.