A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 5

1 0

TESTING | CHARACTERIZATION

NEW TECHNIQUE REDUCES

UNCERTAINTY IN X-RAY

MEASUREMENTS

Scientists at the National Insti-

tute of Standards and Technology

(NIST), Gaithersburg, Md., developed

a new method to reduce uncertainty

in x-ray wavelength measurement that

could provide much anticipated im-

provements. Accurate measurement

of x-ray wavelengths depends on the

ability to measure angles very precise-

ly and with very little margin for error.

The new approach is reportedly the

first major advance since the 1970s in

reducing certain sources of error com-

mon in x-ray angle measurement.

X-ray wavelengths are measured

by passing a beam through special

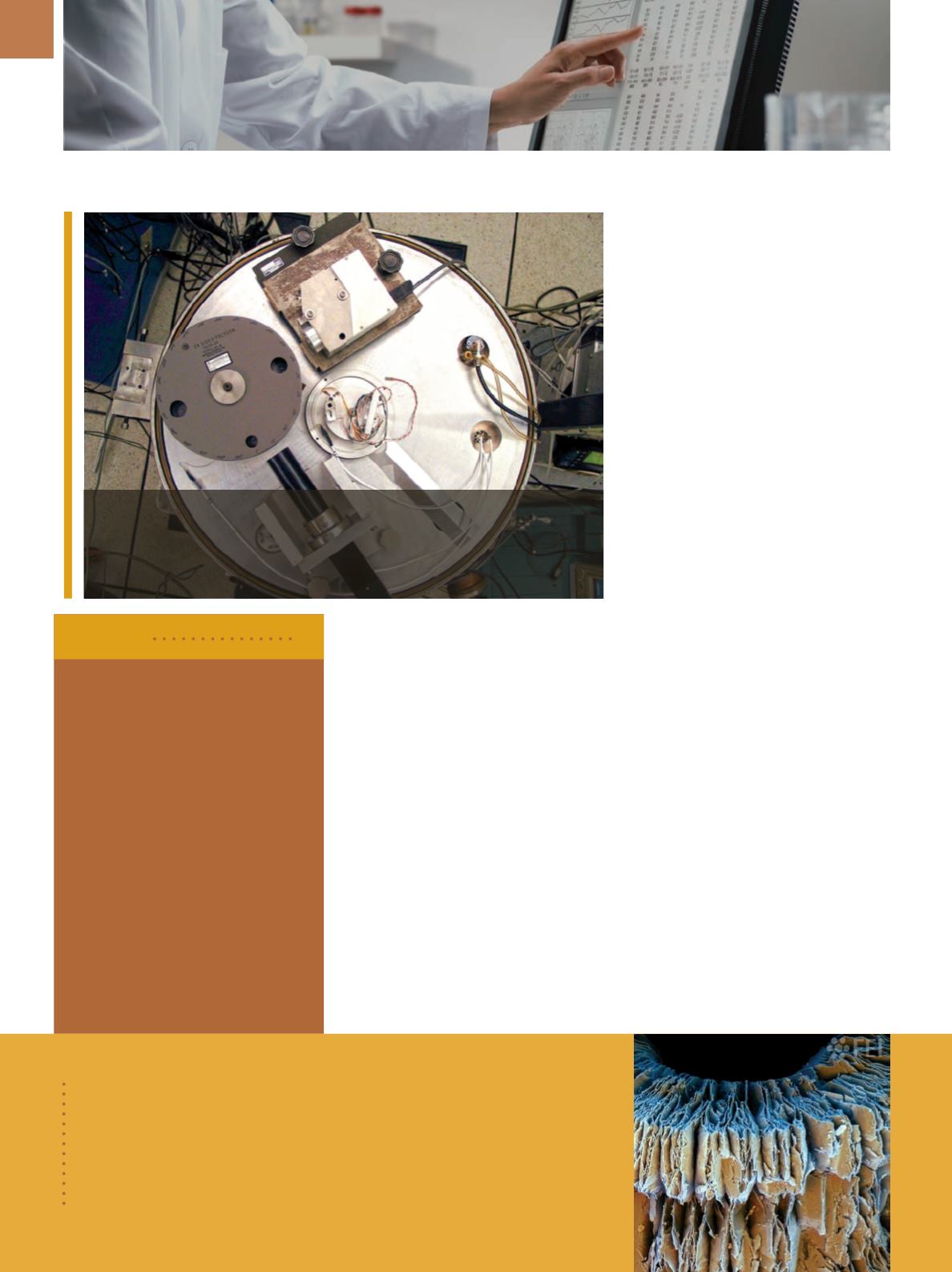

A laser from the NIST-designed autocollimator (square device at top) is beamed at

the mirrored polygon in the gray circle at left, and its reflection allows the angle of

the polygon’s faces to be precisely determined while the polygon rotates. The black

device at the bottom takes measurements that minimize wobbling by the polygon

while spinning. Courtesy of Hudson/NIST.

crystals and carefully measuring the

angle that exiting rays make with

the original beam. The crystal is typ-

ically mounted on a rotating device

that spins the crystal to two different

positions where a spectral line is ob-

served. The angle between the two

is measured, which determines the

line’s position more precisely than a

single measurement would and also

cancels out some potential errors.

However, one limit is the accuracy

of the digital encoder, which trans-

lates the crystal’s rotation to an angle

measurement.

Larry Hudson and his team found

a way to dramatically reduce the er-

ror in that measurement. Their new

approach uses laser beams bouncing

off a mirrored polygon that is rotated

on the same shaft that would carry

the crystal. The approach allows the

team to use additional mathematical

shortcuts to their advantage. With new

NIST sensing instrumentation and

analysis, x-ray angles can now be mea-

sured routinely with an uncertainty of

0.06 arcsec—an accuracy more than

three times better than an uncalibrat-

ed encoder.

Hudson describes this reduction

as significant enough to set world re-

cords in x-ray wavelength measure-

ment. “If a giant windshield wiper

stretched from Washington to New

York City (364 km) and were to sweep

out the angle of one of these errors, its

tip would move less than the width of

a DVD,” he says. Calibrating measure-

ment devices to greater precision will

Granta Design,

UK, released

new software and services that

support rigorous and auditable

composite qualification process-

es. New data were added to the

existing

GRANTA MI: Composites

software package, developed with

input from leading aerospace

companies. The software enables

management of complex data as-

sociated with composite materials,

including layup, cure cycles, direc-

tional properties, and the history

and properties of constituent parts.

grantadesign.com.BRIEFS

Francisco Rangel won

FEI Co.’s

(Hillsboro, Ore.) 2014 Image Contest grand

prize for “Expanded Vermiculite,” a hydrated magnesium-aluminum-iron

silicate. Rangel, who works at the

National Institute of Technology-INT/

MCTI Characterization Center for Nanotechnology Materials and Ca-

talysis,

won airline tickets to London or Washington, a hotel stay, travel

stipend, and two tickets to the IMAX movie,

Mysteries of the Unseen World.

fei.com/image-contest.