Super-strong steel suits military applications and more

Harry Bhadeshia of the Uni-

versity of Cambridge, UK, Depart-

ment of Materials Science and

Metallurgy, has spent the past

three decades researching the na-

ture of steel to develop new alloys

for a range of applications. One of

these alloys, super bainite, has

been licensed to Tata Steel, Mum-

bai, India, and is currently being

manufactured in the UK for use as

super-strong armor for military vehicles and other applications.

Using precise modeling, it was found that there is no lower limit to the temperature at

which bainite can be produced. By heat treating it at temperatures around 200°C for 10 or

more days, a new form results—super bainite. In addition, by adding elements such as sil-

icon and molybdenum, carbides and harmful impurity phases are prevented from forming

in the steel, reducing the likelihood of cracks. Super bainite features a tensile strength of

2.5 GPa, and just 1 m

2

can support a weight equivalent to that of 2.5 billion apples. It has

a higher density of interfaces than any other metal, and is the world’s first bulk nanostruc-

tured metal. The strength of super bainite derives not only from its lack of carbides, but also

from the its tiny iron crystals. These crystals are between 20 and 40 nm thick, comparable

to the width of carbon nanotubes. In comparison, the crystals in conventional bainite are

between 200 and 500 nm thick.

For more information: Harry Bhadeshia,

hkdb@cam.ac.uk,

www.cam.ac.uk.

Protecting helicopters and boats with newmaterials

Emerging global trends impact the environment of light tactical interdiction vehicles

for military, law enforcement, and homeland security operations, particularly helicopters

and patrol boats. As these vehicles engage in higher-risk scenarios, they require enhanced

armor protection that will not compromise their speed, agility, range, and payload capac-

ity. Simply adding armor made from traditional materials such as ceramics, glass, aramid,

and even polyethylene is no longer enough. Innovative lightweight materials that can de-

liver reliable protection and optimize vehicle performance, fuel efficiency, capacity, and

maneuverability are necessary. DSM Dyneema, Stanley, N.C., announces Dyneema Force

Multiplier Technology, which reportedly combines breakthroughs in polymer science,

next-generation UHMWPE fiber technology, and unique unidirectional engineering. The

new material reduces the weight of hard ballistics armor by up to 25%, offering greater ve-

hicle agility, speed, fuel efficiency, and capacity.

dyneema.com.

Shape memory alloys for buildings

Researchers at the Swiss Federal Laboratories for Materials Science and Technology

(Empa) demonstrate that shape memory alloys (SMAs) can be used in the building indus-

try. SMAs have the ability to return to their original shape after being severely deformed,

either spontaneously or following the application of heat,

making them useful not just for making eyeglass frames, but

also for technical applications such as thermostats, stents, and

micro-actuators. Other applications in the construction in-

dustry are possible as well, such as bridge reinforcement.

The nickel titanium alloys used to make eyeglass frames

and stents are not suitable for use in the construction in-

dustry. Iron-based SMA products are much more attrac-

tive, because both the raw materials and processing costs

are far less expensive.

news

industry

briefs

SAE International,

Warrendale,

Pa., is teaming with the

University

of Michigan,

Ann Arbor, to

combine classroom and laboratory

learning in the

Automotive

Composites Technology

Engineering Academy.

The five-

day course will be held November

10-14 at SAE International’s Troy,

Mich., office and will provide an

overview of composite materials in

terms of material types such as

carbon, glass, and natural fibers.

The focus, however, will be on

carbon fiber processes, typical

applications, benefits, and

shortcomings. Participants will

learn about terminology, quality

issues, costs and automotive

market needs, and will gain a

holistic understanding of

automotive carbon fiber

and its applications.

training.sae.org/academies/acad08.Engineers at

Massachusetts

Institute of Technology,

Cambridge, Mass., and

Lawrence

Livermore National Laboratory

(LLNL),

Calif., devised a way to

translate the Eiffel tower to the

microscale—designing a system

that could be fabricated from a

variety of materials, such as

metals or polymers, and that may

set new records for stiffness for a

given weight. The design is based

on the use of microlattices with

nanoscale features, combining

great stiffness and strength with

ultralow density, say researchers.

The actual production of such

materials is made possible by a

high-precision 3D printing process

called projection microstereo-

lithography, as a result of the joint

research.

mit.edu,

llnl.gov.Microscope image of a

single unit of the structure

developed by the team,

called a stretch-dominated

octet truss unit cell, made

from a polymer using 3D

microstereolithography.

M

ETALS

P

OLYMERS

C

ERAMICS

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

8

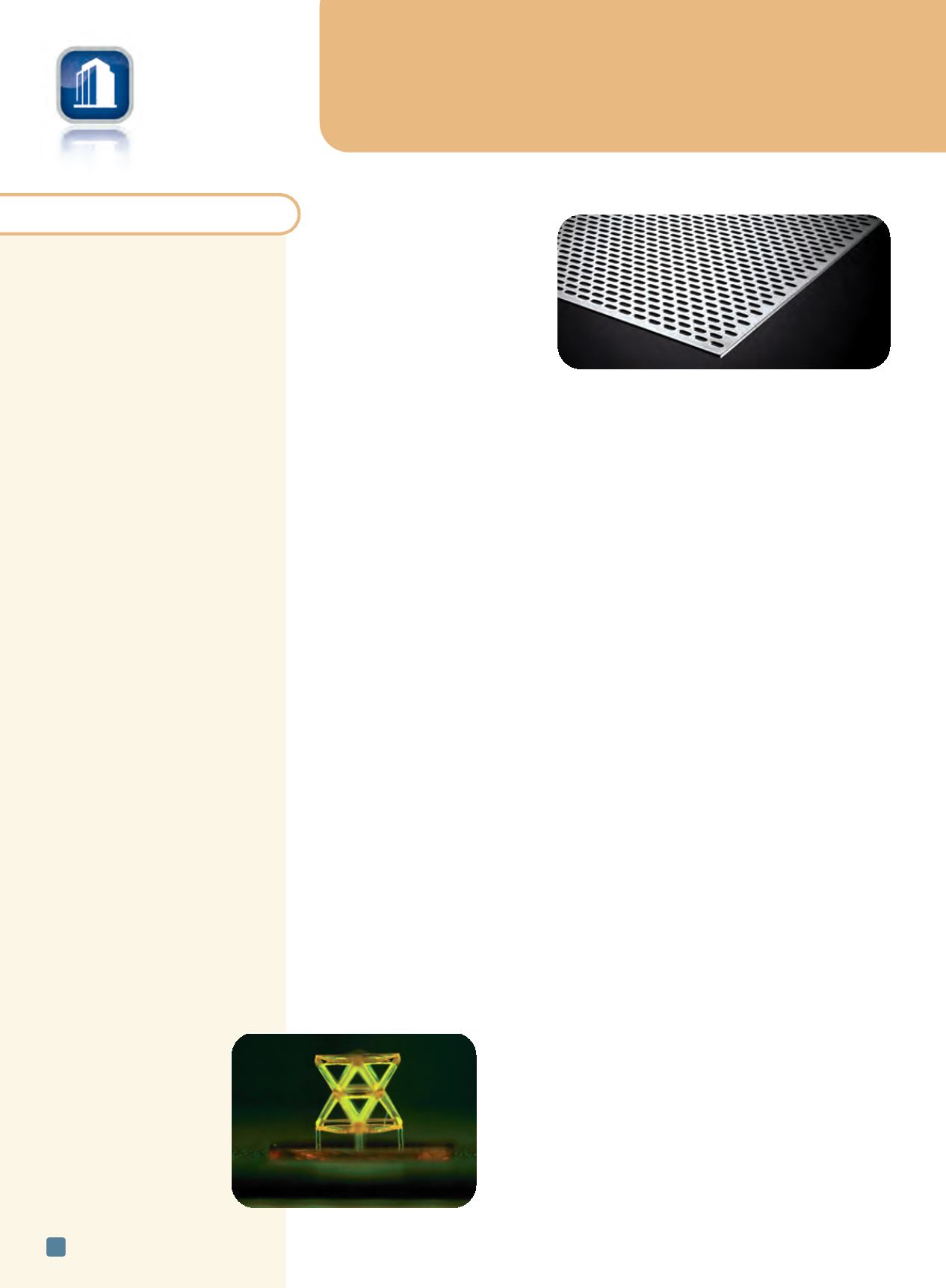

Perforations in super bainite make the material even

better at protecting armored vehicles from projectiles.

Courtesy of Tata Steel.