G

lobal molybdenum production reached a new high of 539.2 million

pounds in 2013, surpassing the 2012 record of 535.2 million lb. Full

year figures from the International Molybdenum Association (IMOA),

London, also show global molybdenum usage at 537.7 million lb, break-

ing the previous year’s record high of 522.5 million lb. Molybdenum is

added to steel and cast iron to improve strength, toughness, hardenabil-

ity, and weldability for numerous applications in the automotive, ship-

building, construction, mining, chemical, oil and gas, and energy

generation industries. In stainless steels and superalloys, it improves cor-

rosion resistance and high-temperature performance and finds uses in

many industrial applications. It is also used in a variety of products from

catalysts and lubricants to pigments and paint.

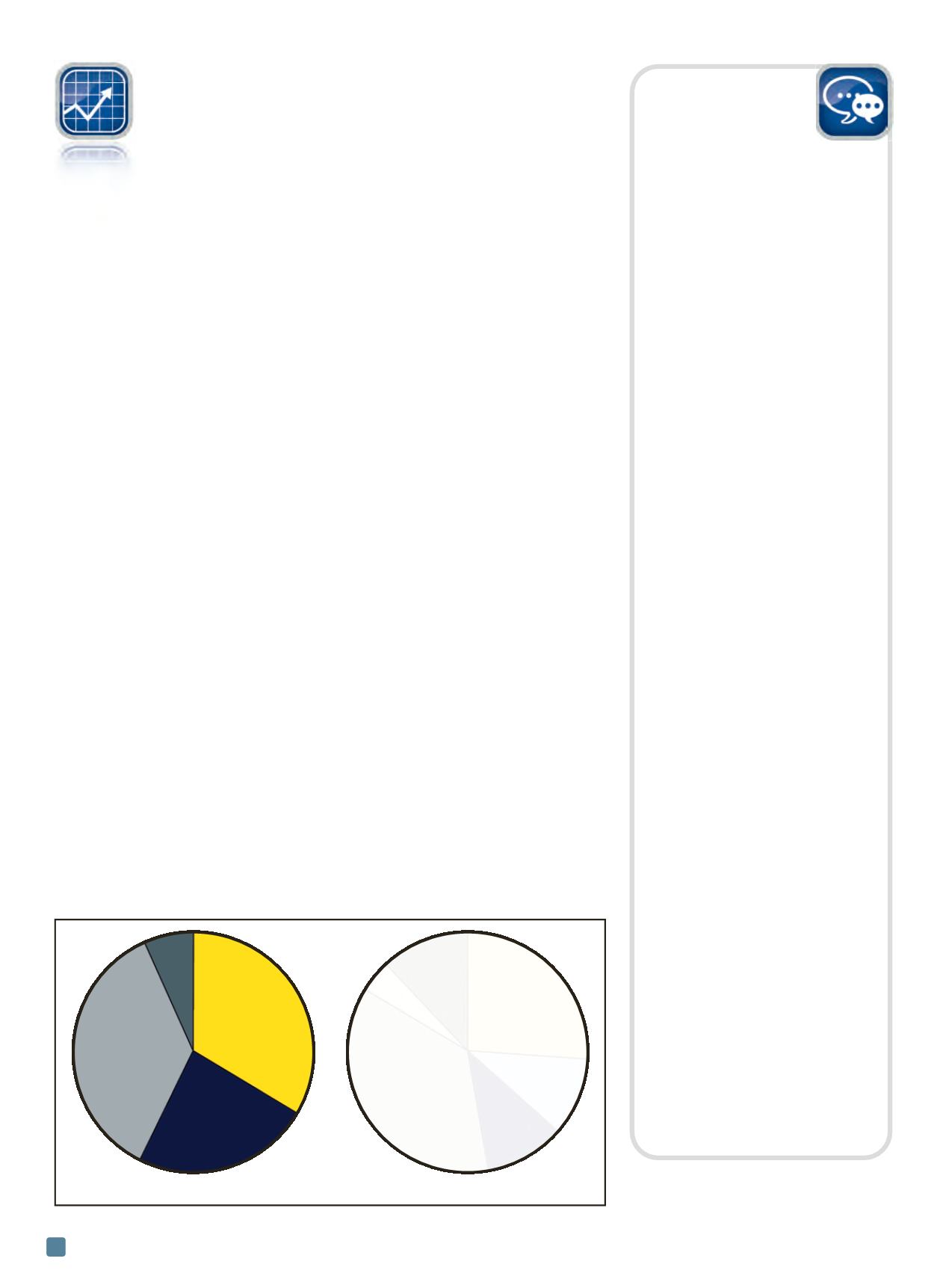

The greatest use of molybdenum in 2013 was in China, where it in-

creased from 188.4 million lb in 2012 to 196.2 million in 2013. Europe

recorded the second biggest share with 140.4 million lb, up from 135.9

million in 2012. Japan and the U.S. were the third and fourth largest users

of molybdenum by region, recording 57.4 and 56.1 million lb respectively.

Usage in the Commonwealth of Independent States (CIS) reached 23 mil-

lion lb, with other countries together totaling 64.6 million lb.

China was also the biggest molybdenum producer in 2013, although

output fell slightly to 194.9 million lb, compared to the previous year’s

record high of 207 million lb. Production in North America rose from

176.5 million lb in 2012 to 180.5 million in 2013. South America was the

third largest producer, accounting for 128 million lb in 2013, up from

118.7 in 2012. Production in other countries increased slightly from 33 to

35.7 million lb in 2013.

Global usage increased from 137.5 million lb in Q3 to 138.2 in Q4.

Usage in China decreased slightly from 52.9 million lb in Q3 to 51.6 in Q4.

In contrast, European usage increased from 34 million lb in Q3 to 35.1 in

Q4. Japan and the U.S. used 14.4 and 14.2 million lb respectively in Q4.

IMOA is a nonprofit trade association representing the interests of

most of the world’s molybdenum producers and converters, as well as

consumers and traders. For more information, visit

www.imoa.info.

ADVANCED MATERIALS & PROCESSES •

SEPTEMBER 2014

4

spot l ight

feedback

market

Global molybdenum production

and use hits record high

Touting titanium for implants

With regard to the recent article

link in the July 23

AM&P

eNewslet-

ter—Microscopic Analysis of Frac-

tured Screws Used as Implants in

Bone Fixation featured in a recent

Journal of Failure Analysis and Pre-

vention

—who published this tripe?

A stainless bone screw that

didn’t

fail would be more newsworthy! I

have published data from 40 years

ago stating that 90% of stainless

onlay plate screws show corrosion

after seven days. This problem was

well known in 1943, when the Army

started using stainless for implants.

If the ham-handed MDs don’t twist

them off during installation, the

chlorides will soon get them. Thread

rolling or machining also introduces

stress into the metal, making it even

more of a risk. Friction (fretting) with

the implant itself destroys the thin

protective skin on the stainless. If it

lives through that, a crevice corro-

sion condition will exist between the

parts. Three strikes, you’re out.

Easy solution: Switch to Ti 6-4 alloy

for all implants. The cost of any

material is a tiny fraction of the

final cost of any device, Pt or Pb, it

makes no difference.

Chuck Dohogne

Mitigating magnesium mayhem

I was pleased to see the excellent

article by Frank Czerwinski on mag-

nesium ignition [Overcoming Barri-

ers of Magnesium Ignition and

Flammability, May]. It does not try to

dodge around the actual flammabil-

ity of this material, especially in the

commonly used alloys, but instead

systematically reports on the re-

search that looks at the fundamen-

tals of what is happening and what

ameliorative steps can be taken.

The connection made between oxi-

dation associated with combustion

and oxidation associated with cor-

rosion seems obvious once made,

but would not have occurred to me

before I read this article. I have

some personal knowledge of this

subject because another participant

in the gas grill industry unwisely

substituted magnesium die casting

alloy for aluminum die casting alloy

in the fireboxes of their gas grills

with rather unfortunate results. A

pity they didn’t belong to ASM!

Alex Gafford

We welcome all comments and

suggestions. Send letters to

frances.richards@asminternational.org.

Other 12%

Europe 26%

China 37% USA 10%

Japan 11%

Other 12%

North America

33%

China 36%

South America 24%

CIS 4%

Molybdenum Production, 2013

Molybdenum Usage, 2013