6 4

A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 6

3D PRINTSHOP

PRINTED COMPONENT

ACES FLIGHT TEST

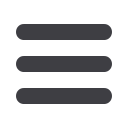

Naval Air Systems Command,

Patuxent River, Md., completed its first

successful flight test of a safety-crit-

ical aircraft component produced

by additive manufacturing (AM). The

component, a titanium link and fit-

ting assembly 3D printed at Naval Air

An MV-22B Osprey equipped with a

3D-printed titanium link and fitting inside

an engine nacelle maintains a hover

during a July 29 demonstration at Patux-

ent River Naval Air Station, Md. Images

courtesy of U.S. Navy.

Warfare Center Aircraft Division, Lake-

hurst, N.J., is one of four that secure

a V-22’s engine nacelle to the primary

wing structure. It will remain on the

test aircraft—an MV-22B Osprey—for

continued evaluation. Prior to this

flight, multiple V-22 components built

at Lakehurst and at Penn State Applied

Research Laboratory, Arlington, Va.,

were tested at Patuxent.

“AM is a game changer,” says Liz

McMichael, AM Integrated Product

Team lead. “We’ll be working with V-22

to go from this first flight demonstra-

tion to a formal configuration change

to use these parts on any V-22 aircraft.”

McMichael and her team have identi-

fied six safety-critical parts they plan

to build and test over the next year for

three U.S. Marine Corps rotorcraft plat-

forms including the V-22, H-1, and CH-

53K. Three of the parts will be made

out of titanium, while the other three

will be stainless steel. Naval aviation

has employed additive manufacturing

as a prototyping tool since the early

1990s and has recently begun print-

ing non-flight-critical parts and tools.

navy.mil.GUINNESS RECORD HOLDER

HEADS TOBOEING

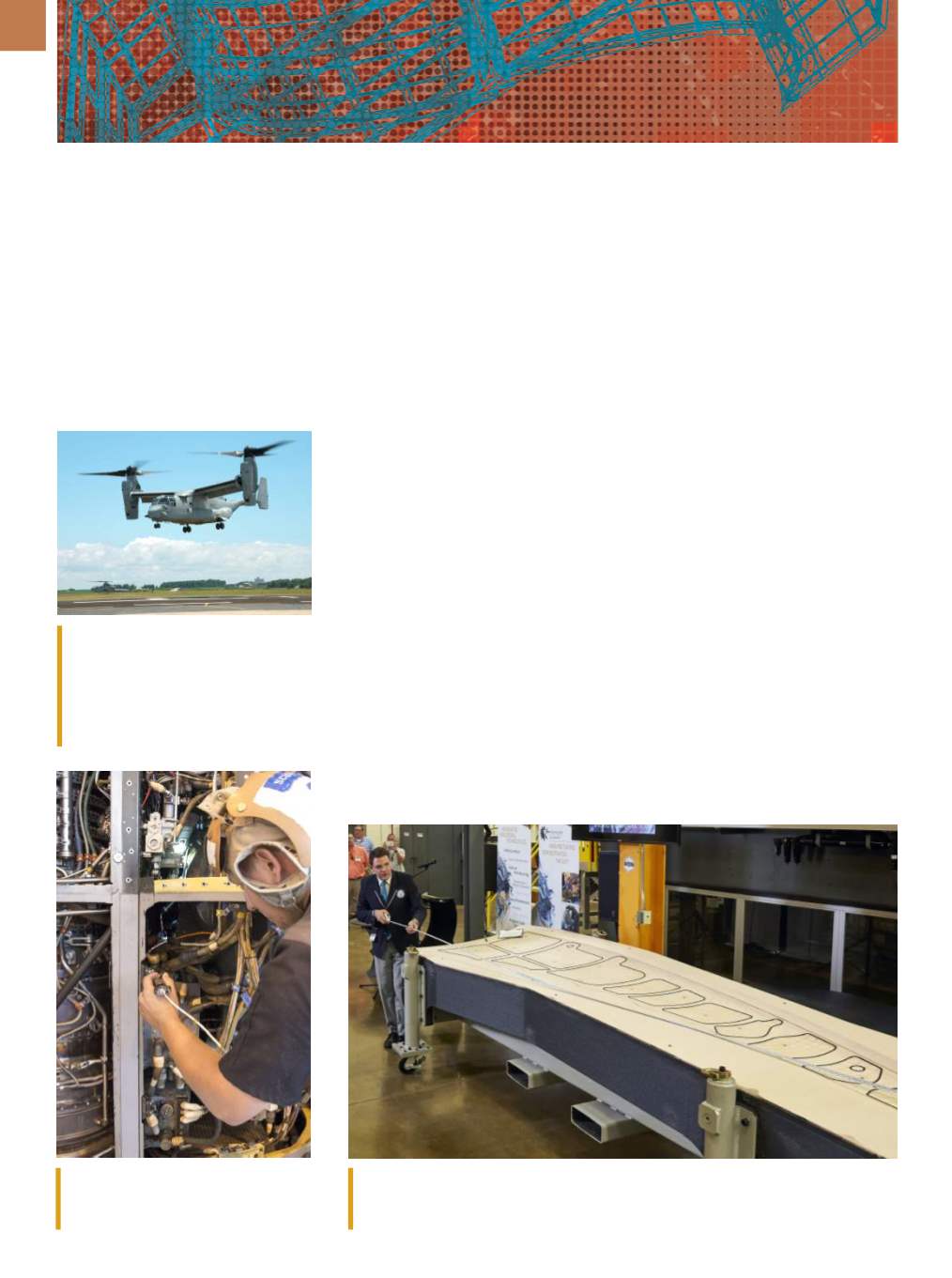

A trim-and-drill tool, developed

by researchers at the DOE’s Oak Ridge

National Laboratory (ORNL), Tenn., was

named the largest solid 3D-printed item

by Guinness World Records. Measuring

17.5 x 5.5 x 1.5 ft and weighing approx.

1650 lb, the tool will be tested for use

in building the Boeing 777X passen-

ger jet. “The more expensive metallic

tooling option we currently use comes

from a supplier and typically takes three

months to manufacture using conven-

tional techniques,” says Leo Christodou-

lou, Boeing’s director of structures and

materials. The new tool was printed on

ORNL’s Big Area Additive Manufacturing

machine in just 30 hours using carbon

fiber and ABS thermoplastic composite

materials. After ORNL completes verifi-

cation testing, Boeing plans to use the

record-setting trim-and-drill tool in its

new St. Louis production facility to se-

cure the jet’s composite wing skin for

drilling and machining before assembly,

providing feedback toORNL on the tool’s

performance along the way.

ornl.gov.Aviation mechanic Cody Schwarz works

to install the 3D-printed link and fitting on

the MV-22B Osprey engine nacelle.

Official measurement of the 3D-printed trim tool co-developed by ORNL and Boeing exceed-

ed the requiredminimum size to achieve the Guinness World Records title of largest solid

3D-printed item.