A D V A N C E D M A T E R I A L S & P R O C E S S E S | M A Y 2 0 1 6

3 8

containing a small amount of

chromium to enrich palladium and

ruthenium on the corroded surface

resulting from selective dissolution

of titanium.

•

Ti-0.5Al-0.35Si (Ti-0.9SA) and

Ti-0.5Al-0.45Si-0.2Nb (Ti-1.2ASN),

which achieve high-temperature

oxidation resistance to 750

°

C via a

combination of aluminum, silicon,

and niobium additions. Also, the

formation of silicides in the matrix

inhibit grain growth.

•

Ti-4.5Al-2Mo-1.6V-0.5Fe-0.3Si-

0.03C (Ti-9), a cold-rolled alloy,

and Ti-4.5Al-4Cr-0.5Fe-0.2C (EL-F),

a forgeable alloy with carbon for

improved high temperature strength.

•

Ti-2Al-1Sn-1Fe-1Cu-0.5Cr-0.3Si

(Ti-2111S), a near-alpha alloy con-

taining low-cost alloying elements

designed for sheet products, which

exhibits lower levels of anisotropic

properties and improved superplas-

tic properties.

Allegheny Technologies Inc. (ATI),

Pittsburgh, and Timet Metals Corp.,

Exton, Pa., developed new

α

+

β

alloys

with improved superplastic forming

(SPF) capability. TIMETAL 54M, or Ti-54M

(Ti-5Al-4V-0.75Mo-0.5Fe), demonstrates

SPF capability at temperatures as low

as 775°C, providing a significant cost

benefit during SPF processing. ATI 425

(Ti-4Al-2.5V-1.5Fe-0.25O) exhibits excel-

lent cold and hot workability, and can

be produced in various forms from coil

to forged products with SPF properties

similar to Ti-54M.

RTI International Metals Inc., Pitts-

burgh, developed a heat treatable

α

+

β

alloy, RTI-XPT (5.5Al-4.3 Zr-5.7V-1.3

Mo-0.10O2-0.06Pd), to compete with

Grade 29 titanium for use in highly

stressed tubular applications used in

high-pressure and high-temperature

corrosive environments. Its corrosion

resistance makes it suitable for sour

and sweet aerated and de-aerated

chloride media at temperatures up to

290°C. RTI-XPT is approved for sour ser-

vice under the ANSI/NACE MR01750/ISO

15156 Standard.

Timet also developed a new tita-

nium alloy for the chemical process

industry targeted for use in aggressive

environments severe enough to require

palladium or rhenium alloys or high-

end industrial nickel alloys. Corrosion

resistance of the new carbon-bearing

alloy is similar to, or better than, that of

the alloys previously mentioned. Mate-

rial costs are dramatically reduced by

not using expensive alloying elements.

Dynamet Techology Inc., Burling-

ton, Mass., developed CermeTi-10, a

titanium carbide particle-reinforced

titanium alloy for die-cast shot sleeve

liners. The alloy reportedly increases

sleeve life up to 20 times longer,

enables three times longer plunger tip

life, reduces maintenance costs, and

results in fewer defects and decreased

lubrication requirements. These lower

cost, lightweight Al components further

enable their use by the auto industry to

meet the federal government’s increas-

ingly strict standards for improved fuel

economy. In a cooperative effort with

Medtronic Inc., Dynamet used another

CermeTi alloy containing particulates

to fabricate the Prestige LP Disc, an

artificial cervical disc. These compo-

nents have been used in Europe since

2004 and are now approved for use in

the U.S. They have a lower wear rate and

produce less scatter on post-operative

MRI scans than stainless steel.

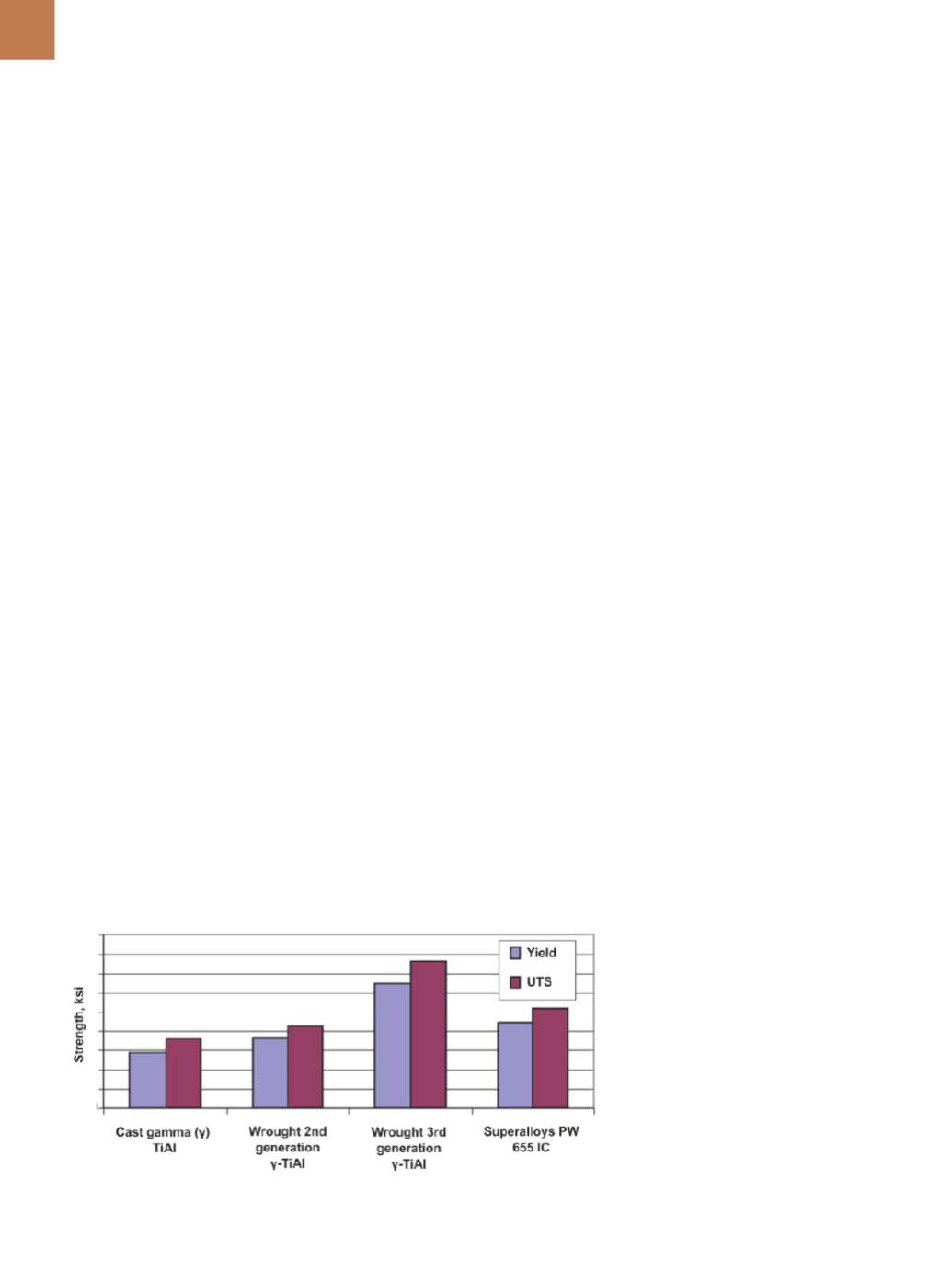

Next-generation aeroengine archi-

tectures challenge the properties of

traditional materials with higher engine

core temperatures and turbine speeds,

which led to development of a third-gen-

eration

γ

-phase containing Ti-aluminide

alloy (Fig. 2). Alloy TNM combines good

processability with required mechanical

properties, resulting in the first appli-

cation of forged

γ

-TiAl turbine blades

jointly developed by Pratt &Whitney and

MTU Aero Engines, Munich.

NEW CHARACTERIZATION

METHODS

Advanced characterization meth-

ods such as atomic-force spectroscopy

(AFS), high resolution digital image

correlation (DIC), and scanning trans-

mission electron microscopy (STEM)

provide the means to understand phase

transformations and deformationmech-

anisms under a variety of external condi-

tions. These techniques were discussed

during several conference sessions.

For example, researchers at Univer-

sity of Manchester, UK, are combining

electron backscatter diffraction (EBSD)

orientation maps and high resolution

DIC to observe nanoscale strain behav-

ior in Ti-6Al-4V with varying degrees

of microtexture. Two extreme micro-

structures show noticeable differences

in strain heterogeneity, with the strong

microtexture sample exhibiting a higher

density of slip traces with increased

maximum shear strains. Nanoscale

deformation studies provide more

detailed insight into the actual extent of

the strain heterogeneity, with maximum

shear strain intensities of approximately

10 times the applied strain.

Spatially resolved acoustic spec-

troscopy (SRAS), a laser-basedultrasonic

method that resolves crystal orientation

in titanium, was developed at Univer-

sity of Nottingham, UK. The technique

is based on local surface acoustic wave

velocity in different directions to image

Fig. 2 —

Comparison of room-temperature strength of third-generation forged

γ

-TiAl alloy with

other materials used as low-pressure turbine blades in the PW1000G engine.