A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

M A Y

2 0 1 6

3 7

CONFERENCE HIGHLIGHTS

ADVANCEMENTS IN TITANIUM

TECHNOLOGY

Developments in titanium technology and opportunities for increased use in several

markets were highlighted at the 13th World Conference on Titanium (Ti-2015).

Vasisht Venkatesh, Pratt & Whitney, East Hartford, Conn.

Rodney Boyer (retired), Boeing, and RBTi Consulting, Bellevue, Wash.

Many of these developments were

discussed at the 13th World Conference

on Titanium, held during August 2015 in

San Diego, Calif. This article highlights

some of the major advancements pre-

sented at the conference.

NEW ALLOY DEVELOPMENT

Conventional titanium alloys are

typically limited to a maximum tem-

perature of roughly 500°-550°C due to

poor oxidation resistance. In addition,

severe grain growth in single-phase

titanium alloys at elevated tempera-

tures degrades its mechanical prop-

erties. During a few of the conference

sessions, recent titanium develop-

ments were presented to provide an

overview of the industry. For example,

Kobe Steel Ltd., Japan, developed sev-

eral titanium alloys over the past two

decades including:

•

Ti-0.4Ni-0.015Pd-0.025Ru-0.14Cr

(AKOT), a corrosion-resistant alloy

T

he aerospace sector consumes

more than 70% of all titanium

produced in the U.S., but major

opportunities exist for increased use

in the automotive and biomedical sec-

tors, as well as other industrial sectors.

This is being driven by factors such as

new process development to lower

manufacturing costs, enhancing per-

formance of existing and new titanium

alloys to meet new application require-

ments, and development of computa-

tional models to both reduce new alloy

development cycle times and acceler-

ate new process qualification times at

reduced cost.

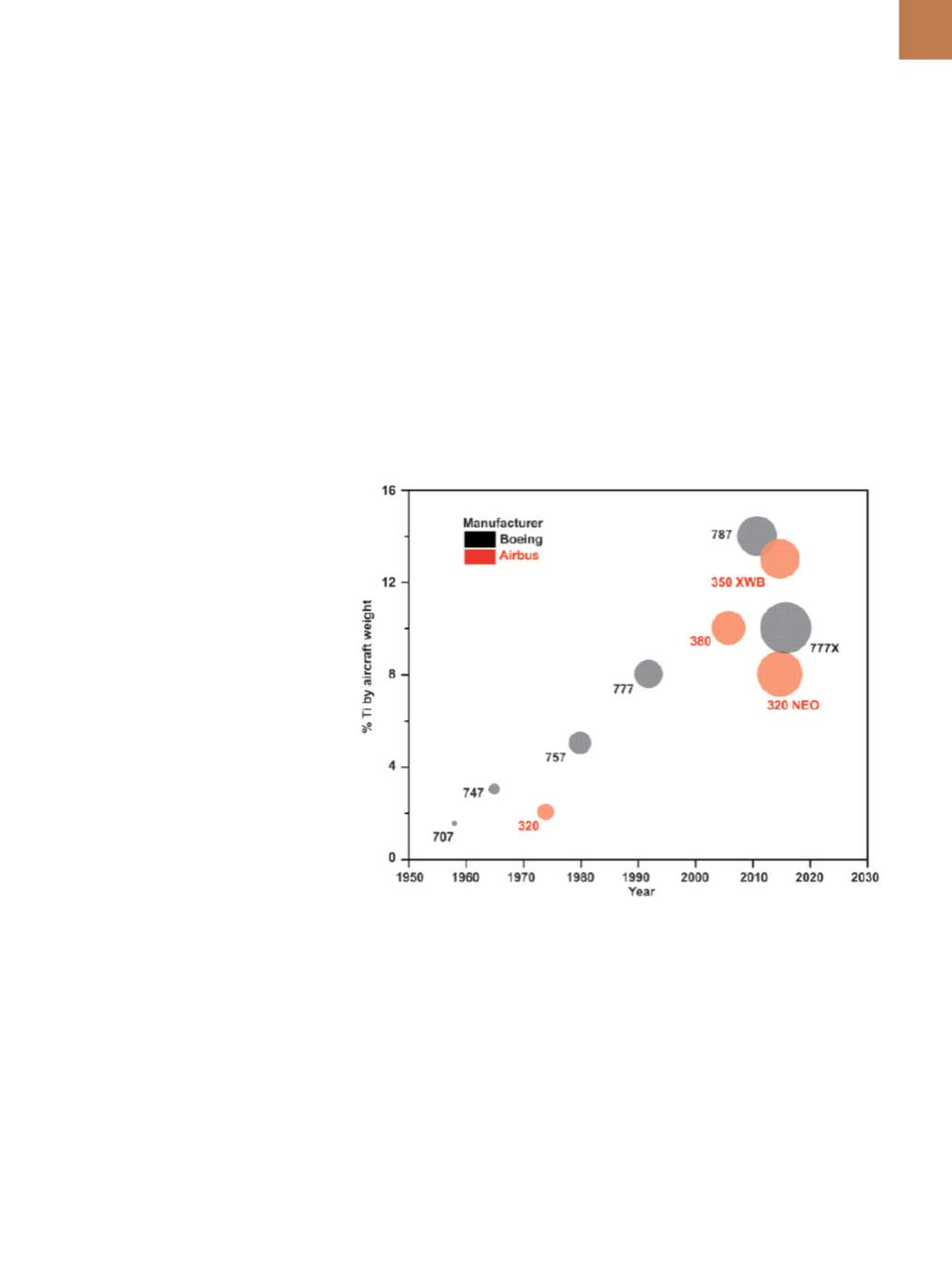

The aerospace industry is contin-

ually looking for titanium products for

next-generation airframes and engines

to meet stringent fuel efficiency stan-

dards and cost pressures associated

with large orders for new aircraft

such as the B787, B777X, B737MAX,

A320NEO, A350XWB, and A380 (Fig. 1).

Thus, some of the latest developments

focus on growing titanium use through

innovation in key capabilities and

reduced final component costs. Exam-

ples include development and qualifi-

cation of a third-generation forgeable

γ

-TiAl for low-pressure turbine blades

in the Pratt & Whitney PW1000G engine

and evaluation of new

α

+

β

alloys for

superplastically formed nacelle compo-

nents in next-generation airframes and

engines.

Fig. 1 —

Increased titanium use in aircraft over the past several decades. Bubble size indicates

aircraft passenger capacity

[1]

.