A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 6

3 5

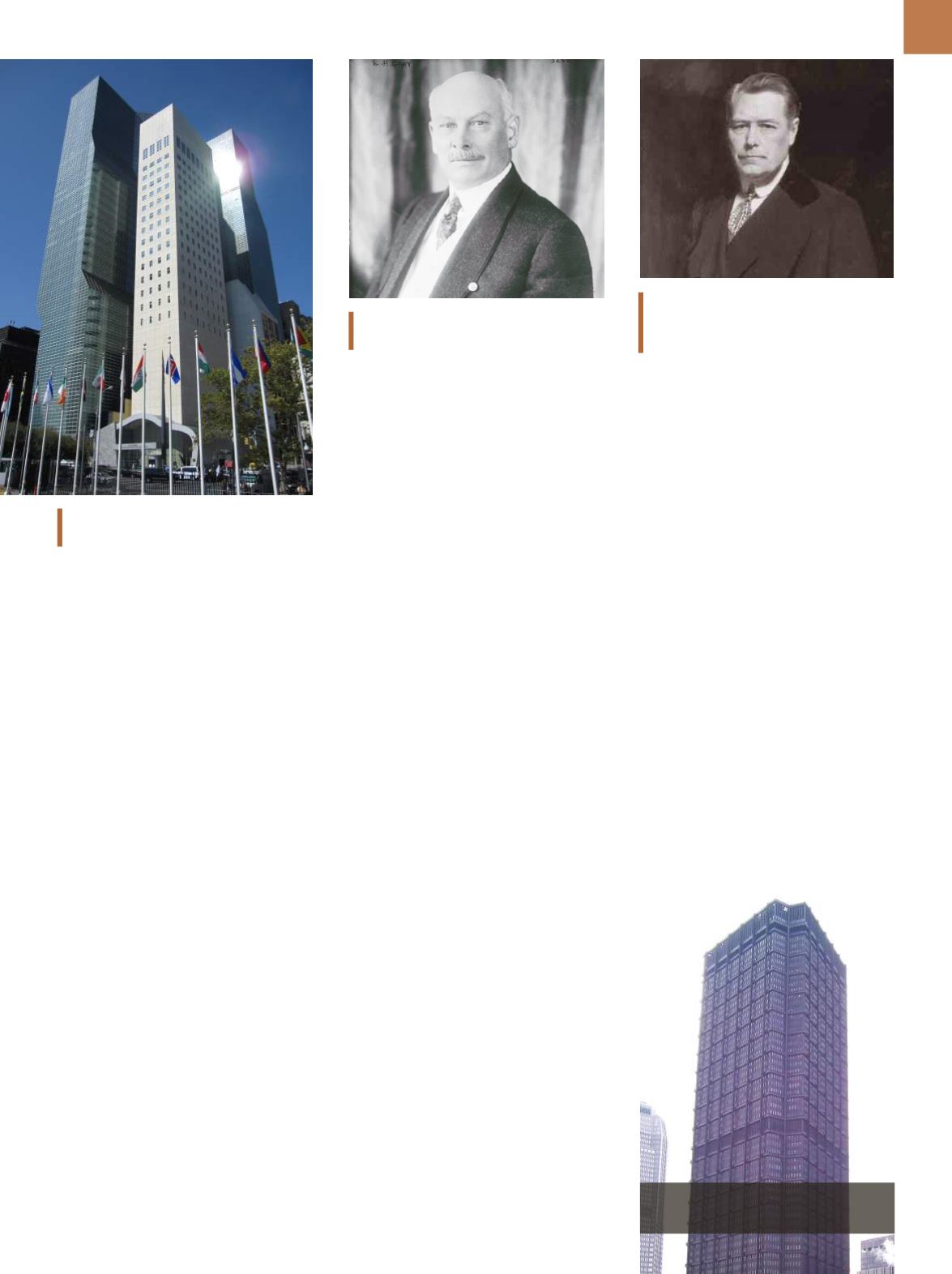

Judge Elbert Henry Gary, the first chair-

man of USS. Circa 1915.

WARTIME EFFORTS

By 1940, the defense effort in-

creased to rebuild the U.S. armed forc-

es, in addition to helping England and

France through the lend-lease program.

During the five years leading up to Ja-

pan’s surrender, the U.S. produced

$190 billion in armament with a third

of all steel made by USS. For example, a

USS mill in Lorain, Ohio, produced over

1200 miles of 24-inch-diameter pipe

for the big pipeline carrying oil from

Texas to New Jersey. The Corporation

built a new government funded steel

mill at Geneva, Utah, to supply steel for

the West Coast shipbuilding industry.

Throughout the war, the USS American

Bridge Division erected several govern-

ment funded factories and buildings.

The post war era saw the cancella-

tion of nearly all government contracts

with severe unemployment. With the

conversion back to consumer goods

and the introduction of new technol-

ogies developed during the war, the

economy soon revived with demand

for steel exceeding wartime levels. The

1950s was the most prosperous decade

since the 1920s beginning with the Ko-

rean conflict, which again increased de-

mand for armament. This resulted in the

Cold War and the continued need for a

strong defense industry. New technolo-

gies such as the nuclear powered navy

and the beginning of the nuclear power

energy industry increased demand for

steel. The auto industry was building

more and heavier cars and applianc-

es became household necessities. In

addition—for the first time since con-

struction of the Empire State Building

in 1931—a new high-rise was erected,

the United Nations headquarters in New

York. The 1950s would see the beginning

of a boom in such buildings, and the

Federal-AidHighway Act of 1956 (tobuild

the interstate highway system) added to

the steel demand as well.

STEEL INDUSTRY BOOMS

With the increasing use of steel,

USS started a program of modernizing

its older mills and adding equipment

for new products. The most ambitious

project was a new steel works at a ru-

ral site on the Delaware River in Penn-

sylvania at the New Jersey border. This

works required all the infrastructure

of rail lines, a harbor for unloading ore

ships, blast furnaces, open hearth fur-

naces, coke ovens, and rolling mills for

various products. The iron ore for this

mill would be imported from a deposit

owned by USS in Venezuela. This plant

was the largest ever built in the United

States on a new site. Also, a new town

was built several miles away to house

workers and all the related services. The

plant was named The Fairless Works

and the town named Fairless Hills after

the new chairman, Benjamin Fairless.

The Corporation built a new

headquarters in Pittsburgh in 1953—a

41-story building using steel and stone.

In 1956, they built a new research and

development campus at Monroeville

near Pittsburgh. USS had first estab-

lished a central research laboratory in

1928 at Kearny, N.J., in an unused build-

ing in the Federal Shipbuilding and Dry-

dock Co., a division of the company.

One of the first research employees was

Edgar Bain who would become world

famous for his studies on the transfor-

mation of austenite to pearlite at con-

stant subcritical temperatures. A funda-

mental research laboratory on the new

campus was named in his honor.

The 1950s would end with the

understanding that there was a great

future for steel and it would be led by

The Corporation. However, in the last

months of 1959, negotiations between

the major integrated steel industry and

the United Steel Workers Union ended

with a four-month strike that even-

tually changed the industry beyond

recognition.

For more information:

Charles R.

Simcoe can be reached at

crsimcoe1@ gmail.com.

Myron Charles Taylor, the second

chairman of USS who led the company

through the Great Depression.

United Nations Headquarters, the first

high-rise built after the Great Depression.

Headquarters of The Corporation,

erected in Pittsburgh, 1953.