A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 6

3 4

METALLURGY LANE

Metallurgy Lane, authored by ASM life member Charles R. Simcoe, is a continuing series dedicated to the early history of the U.S.

metals and materials industries along with key milestones and developments.

THE INTEGRATED STEEL INDUSTRY—PART I

THE BEGINNING OF THE BIG INTEGRATED STEEL INDUSTRY BEGAN WITH

THE FORMATION OF THE UNITED STATES STEEL CORPORATION IN 1901.

U

nited States Steel Corporation,

known simply as “The Corpora-

tion” for the century that followed

its debut, was initially composed of the

Carnegie Steel Co. as its biggest produc-

er and the Federal Steel Co. as number

two. Carnegie Steel was well known as

the leading steel company in the Besse-

mer steel age from 1875 to 1900. Federal

Steel was an unknown company assem-

bled by a lawyer and judge named Elbert

H. Gary from Illinois who had combined

nearly 40 plants making wire. This group

was financed by J.P. Morgan who would

eventually lead the financing of General

Electric Co., International Harvester, and

United States Steel (USS). Judge Gary

was the first chairman of USS in 1902

and Charles Schwab of Carnegie Steel

was the first president.

The new USS owned plants and fa-

cilities of iron ore, coke, wire, plate, and

tube, in addition to the American Bridge

Co. They had 213 steel mills, 41 iron

mines, 112 ore boats, and 57,000 acres

of coal mines. The company was capi-

talized at $1.4 billion and shares were

offered for sale to the public. In the first

full year of operations, revenues were

$560 million and earnings were $34 mil-

lion. After a year as president, Schwab

was forced out of the company over dif-

ferences with Gary. Schwab was used

to having free rein at Carnegie Steel

and did not fit in with the corporate

image under Gary. Schwab would later

become president of Bethlehem Steel,

which he would lead to be a major com-

petitor of USS.

EARLY 1900s

In the early 1900s, most steel

mills were still located in the east. In

1906, Judge Gary decided that The

Corporation would build a big new mill

in Indiana, bordering on Lake Michigan.

This isolated location required building

all the infrastructure needed for an inte-

grated steel mill with railroads, a harbor

for receiving raw materials, and a new

town for workers and service person-

nel. The project was enormous for the

time and this steel mill would be among

the largest in the world. By 1911, the

city—named Gary in honor of the chair-

man—had a hotel, hospital, churches,

and homes for a population of nearly

20,000. The steel plant housed eight

blast furnaces, 47 open hearth furnac-

es, hundreds of coke ovens, and rolling

mills to produce railroad rails, axles,

and bars. Later, sheet and plate mills

would be installed for the new auto and

home appliance industries.

As The Corporation grew, it relied

on immigrants for labor, just as Andrew

Carnegie had in the 1880s and 90s. In

1910, half theworkers were fromPoland

or the Slavic countries. This kept labor

costs to a minimum, but would lead to

problems in the future. In WWI, the new

supply of immigrants was closed and

recruits of African Americans from the

south filled the labor needs. There were

3000 in Gary and 4000 in Pittsburgh

by 1919. With the war over, wages and

working conditions led to strikes in

many plants. At Gary, the Indiana State

Guard was called to restore order.

ROARING TWENTIES AND THE

GREAT DEPRESSION

The Corporation enjoyed success-

ful years during the 1920s. With the

booming auto industry’s need for steel,

they built sheet mills in Gary, as well as

Pennsylvania, Ohio, and Alabama. They

also built pipe mills to supply the ever

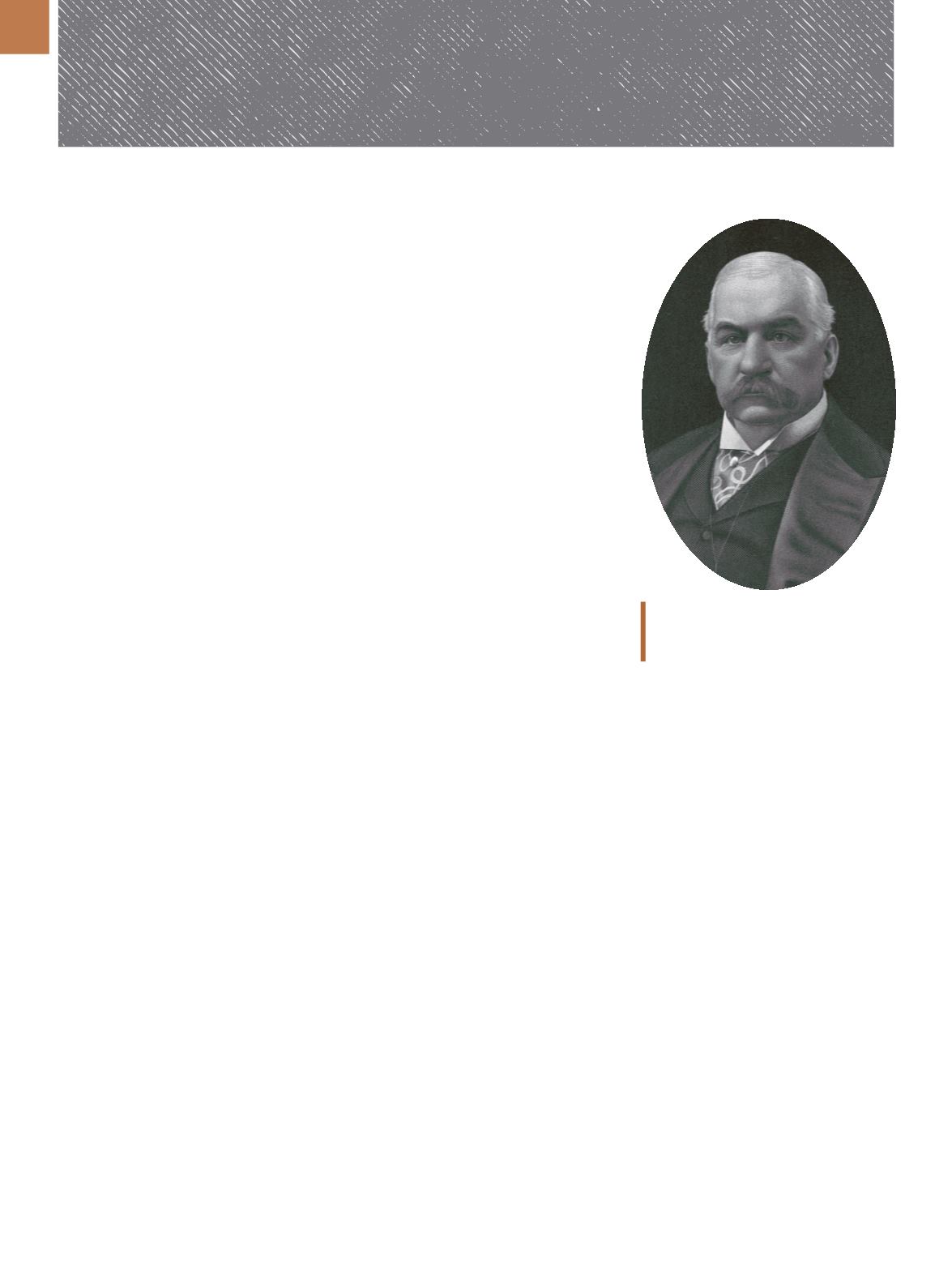

John Pierpont (J.P.) Morgan, the financier

who assembledmany companies to form

United States Steel Corp. Circa 1918.

increasing oil production. During this

10-year period, total earnings reached

$1 billion with two-thirds of that paid

in dividends. All of this success was ac-

complished under Judge Gary who con-

tinued to work until he was 80 years old.

With the depression of the 1930s,

steel demand plummeted. The Corpo-

ration produced 14 million tons of steel

during the peak year of 1929. In 1933,

they only produced 3.8 million. The loss

that year was $91 million with 80,000

workers compared with 240,000 during

the 1920s. At the lowest point in 1933,

plants were operating at 9% capacity.

Production increased as government

programs began construction under

the Works Progress Administration

(WPA) and auto sales increased during

the 1930s. USS appointed Myron Taylor

as its new chairman in 1932 to replace

Judge Gary. Taylor would lead the com-

pany through the difficult times and

build five million tons of new capacity

while eliminating the same amount of

obsolete production.