A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 5

4 8

SUCCESS ANALYSIS

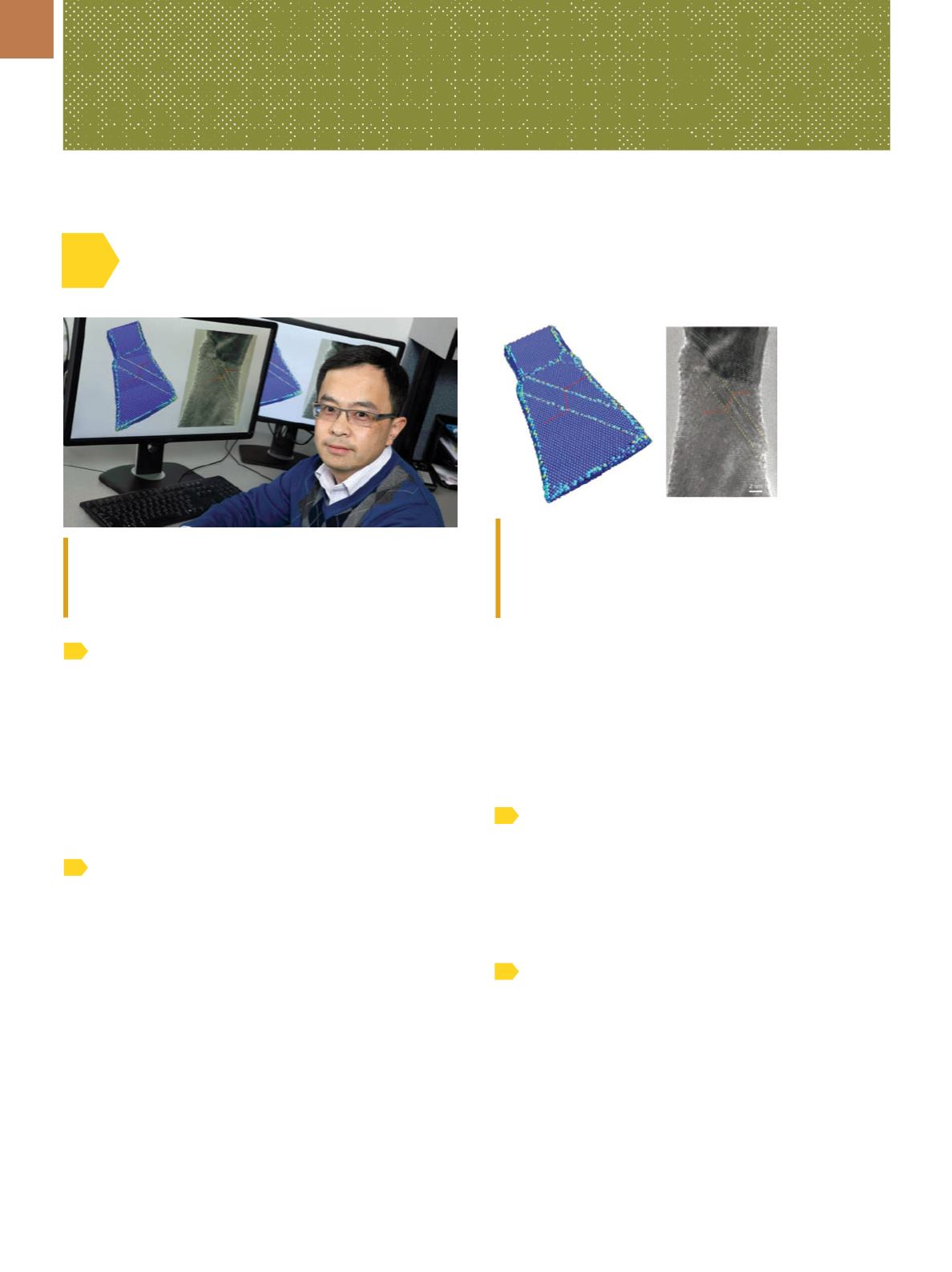

SPECIMEN: TUNGSTEN NANOCRYSTALS

VITAL STATISTICS

Researchers at the University of Pittsburgh, Drexel Uni-

versity, and the Georgia Institute of Technology designed a

new way to study atomic-scale deformation mechanisms,

revealing an interesting phenomenon in tungsten. The group

is reportedly the first to observe atomic-level deformation

twinning in bcc tungsten nanocrystals. Twinning has been

observed in large-scale bcc metals and alloys during deforma-

tion. However, whether twinning occurs in bcc nanomaterials

was unknown until now.

SUCCESS FACTORS

Observation of atomic-scale twinning was made inside

a transmission electron microscope (TEM). This kind of study

was previously impossible because TEM imaging requires

samples less than 100 nm in size and it is difficult to make

bcc samples that small. Graduate student Jiangwei Wang and

Professor Scott Mao, both at the University of Pittsburgh, de-

signed a novel way of making bcc tungsten nanowires. Under

a TEM, two small pieces of individual nanoscale tungsten crys-

tals were welded together, creating a wire about 20 nm in di-

ameter. This wire was durable enough to stretch and compress

while the twinning phenomenon was observed in real-time

using a high-resolution TEM.

Next, Christopher Weinberger, an assistant professor at

Drexel University, developed computer models that show the

mechanical behavior of the tungsten nanostructure at the

atomic level. Along with Weinberger’s modeling, Ting Zhu,

an associate professor at Georgia Tech, conducted advanced

computer simulations, using molecular dynamics to study

deformation processes in 3D. Zhu’s simulation reveals that

tungsten’s strength behavior is not without problems. “If you

reduce the size to the nanometer scale, strength can be in-

creased by several orders or magnitude,” says Zhu. “But there

is a dramatic decrease in the ductility. We want to increase

strength without compromising ductility, so we need to under-

stand the controlling deformation mechanisms.”

ABOUT THE INNOVATORS

Scott Mao is a professor in the Swanson School of Engi-

neering at the University of Pittsburgh and Jiangwei Wang is

a graduate student. Christopher Weinberger is an assistant

professor in Drexel’s College of Engineering and Ting Zhu is an

associate professor in the Woodruff School of Mechanical En-

gineering at Georgia Tech.

WHAT’S NEXT

Results should lead to further investigation of deforma-

tion mechanisms in nanoscale metals and alloys, ultimately

enabling the design of nanostructured materials to fully real-

ize their latent mechanical strength, say researchers.

Contact Details

Scott Mao, University of Pittsburgh

Swanson School of Engineering

3700 O’Hara St.

Pittsburgh, PA 15261

412.624.9602,

sxm2@pitt.edu, www.engineering.pitt.eduTing Zhu of Georgia Tech, worked with colleagues at the University

of Pittsburgh and Drexel University to develop a better under-

standing of a key deformation mechanism in nanoscale tungsten.

Courtesy of Candler Hobbs.

The computer model (left) and experimental image (right) reveal

atomic-level deformation twinning in a tungsten nanowire under

axial compression. The lattice of the deformation-induced twin

band (between yellow lines) is a mirror image of that of the parent

crystal. Courtesy of Ting Zhu.