48

Specimen Name:

NIST nSoft Consortium

Vital Statistics:

“Soft materials” are the basis of plastics and composites—critical

for producing everything from consumer goods to automobiles,

but the light elements in these materials are difficult to observe and

study with traditional tools. Neutrons, however, interact strongly

with these light elements and are ideal for studying soft materials.

The NIST Center for Neutron Research (NCNR) operates facilities

designed for users from both industry and academia to study

neutron interactions with matter.

The goal of NIST’s nSoft Consortium is to bring together

companies and enable them to use neutron measurements to

improve products made from soft matter. NIST scientists share

their experience with member companies and together they work

to identify and develop new measurement tools for understanding

soft materials. Members participate in experiments, training

programs, and meetings that enable them to adopt neutron-based

tools into their research plans and conduct their own proprietary research using NIST facilities.

Success Factors:

Formal operations at nSoft started with a kickoff meeting on August 14, 2012, and included a

dozen companies from industries such as petroleum-based energy products, basic chemicals,

consumer goods, and pharmaceuticals. The consortium’s main technical objectives are to explore

material morphology and topology, materials characterization under flow and strain, and shear and structure of soft

material interfaces.

Molecular topology is a critical parameter of manufacturing soft

materials. nSoft is developing neutron scattering and imaging methods

to measure the spatial position and shape of long-chain branched

polyolefins, used to control the flow rate and mechanical properties of

the commodity plastics industry.

Incorporating a Couette rheometer on a SANS instrument (“rheo-

SANS”) demonstrates the capacity of neutrons to probe soft materials

under dynamic conditions. nSoft will build on this effort at the NCNR to

develop in situ measurements using a Sentmanat extensional rheometer,

large amplitude oscillatory shear technology, and hyperbolic inlets to

measure materials under high shear rates (approaching 1 million s-1).

About the Innovators:

The consortium is led by nSoft director Ronald Jones and NIST

researchers Eric Lin, Dan Neumann, and Robert Dimeo. Members

include Dow Chemical, DuPont, Genentech, Kimberly-Clark,

MedImmune, Solvay, Chevron Phillips, ExxonMobil, and several others.

What’s Next:

Soft materials are defined by their interfaces, including surfactants at an

oil/water interface, polymer adsorbtion at a filler interface in composites, and

the interphase between amorphous and crystalline regions in polyolefins.

Depth penetration and sensitivity to contrast variations at internal interfaces

allow neutrons to probe soft material interfaces, even during application of

shear. Methods such as the overflowing cylinder, dynamic Langmuir trough,

and time-resolved SANS are in development to probe this key component of

material design for manufacturing.

Contact Details:

Ronald Jones, nSoft Director

NIST Material Measur

ement Laboratory and Center for Neutron Research

100 Bure

au Dr., Gaithersburg, MD 20899-8553

301/975-4624,

ronald.jones@nist.gov, www.nist.gov/nSoft

A flow cell being developed for

interfacial studies of soft materials and

fluids.

SucceSS AnAlySiS

ADVANCED MATERIALS & PROCESSES •

APRIL 2014

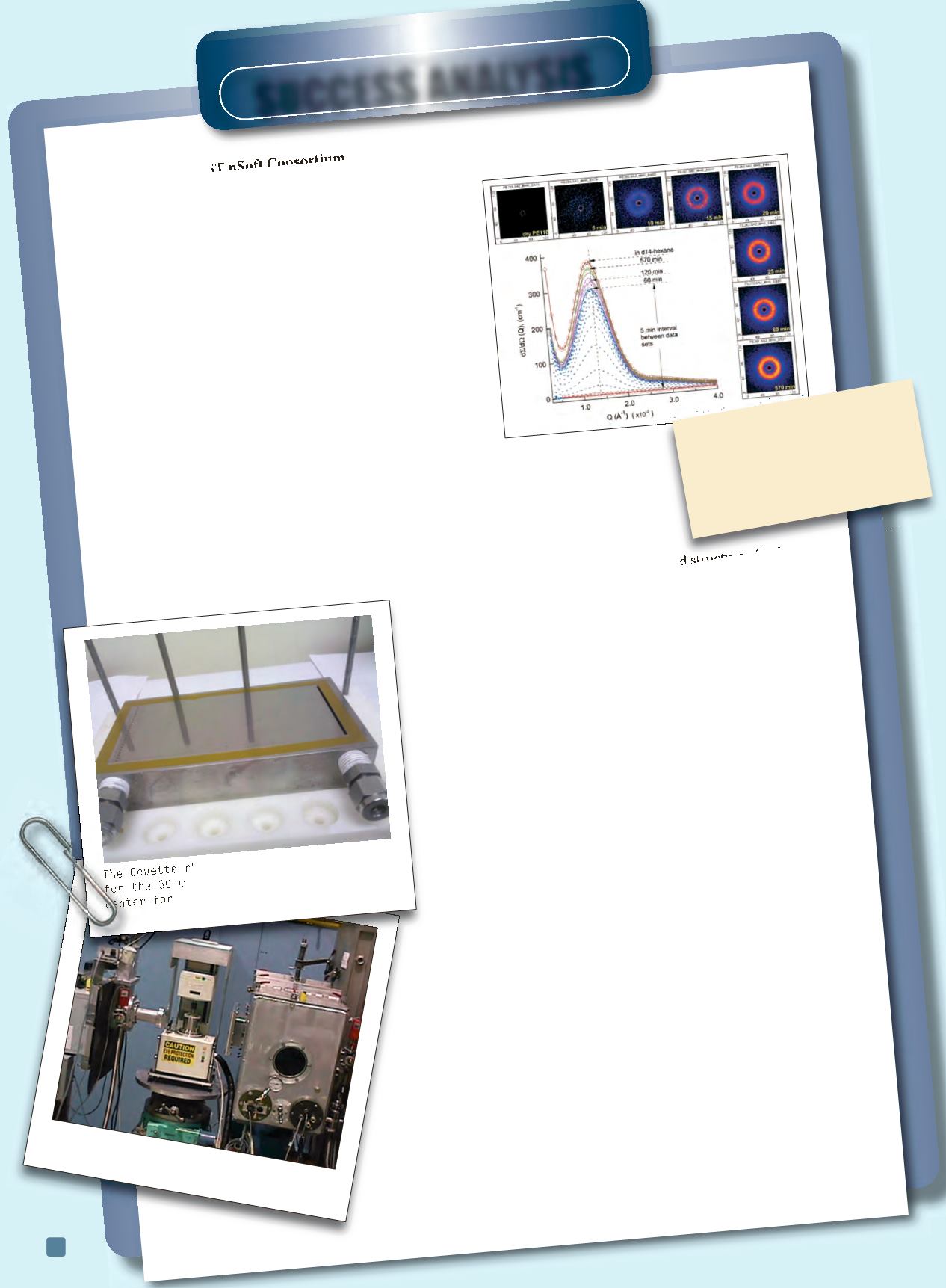

The Couette rheometer sample environment

for the 30-m SANS instrument at the NIST

Center for Neutron Research.

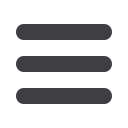

Small angle neutron scattering

(SANS) data demonstrate

increasing contrast of the long

period of a linear polyethylene

with increasing exposure time

to d-cyclohexane vapor (from

Kim and Glinka, 2009).